CMM (Coordinate Measuring Machine)

Portable Measurement and What it Means for Manufacturing

Portable measurement devices entered the manufacturing scene in recent years and have been revolutionizing inspection processes since. In the following, you’ll explore the details of portable measurement and its implications for the manufacturing industry.

The Evolution of Measurement in Manufacturing

Although the beginnings of modern manufacturing may have taken a while to evolve, this isn’t the case today. With each passing year, technology continues to propel manufacturing processes into a more efficient and productive era.

This can clearly be seen with the help of portable CMMs, as they’ve made shop floor measurements, a once-impossible process for high tech measurement devices, entirely seamless.

Manual measurements with subjective tools used to be the only solution, but once inspection graduated from basic tool measurements and isolated CMMs in QC labs to the invention of handheld coordinate measuring machines, it produced a completely different output. Measurements in manufacturing aside, it helps to look at the details of portable measuring instruments to understand the true impact on the industry.

Get detailed information on our products by downloading our catalog.

View Catalog

Understanding Portable Measurement

The finest measurements are crucial in any form of manufacturing to ensure consistency, accuracy, and a quality product. For decades, this reliance on quality has stemmed from manual expertise. While this is still needed today and has achieved amazing feats, it still comes with the issue of human error.

Portable measurement systems are becoming a growing norm in manufacturing and quality control processes to help mitigate and eliminate this error.

Some of the key benefits of portable CMM machines include:

- Improved accessibility around the shop floor

- Easier monitoring of ongoing processes

- Reduced costs around labor and resources

- Automated Reporting

- Accurate Results

Of the notable points, portable CMMs for manufacturing processes can be utilized anywhere on the shop floor, but they can also be kept in a QC lab if desired. They have multiple mounting options, so these systems can truly go anywhere, whether it be on a tripod on the floor, or mounted on the ceiling.

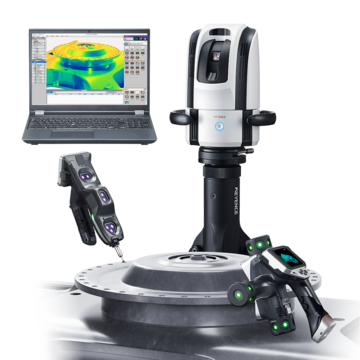

The head unit of the portable CMM works by locating a probe in a given space using cameras, delivering degrees of freedom that no other CMM experiences. Regarding the device itself, it is helpful to note that there are different portable CMM types on the market, with an impressive range of capabilities.

We’re here to provide you with more details.

Reach out today!

What are Portable Measurement Devices?

So far, it is clear that portable measurement devices are made for manufacturing, but what exactly do they do? From a technical perspective, it can get convoluted, but what they do and what they can accomplish is relatively straightforward.

The primary focus of portable CMMs is to take measurements and create inspection reports to convey accurate results. These measurements include all geometrical and dimensional features of an object. Modern CMMs have also made significant advancements in reverse engineering practices. Reporting and output are more accurate, and portable CMMs are much more efficient than other related tools.

The Advantages of Portable Measurement in Manufacturing

Many of the points mentioned so far focus on measurement capabilities and how they work. Now, it is time to delve into their advantages in the manufacturing process as a whole.

While efficiency, productivity, and quality are high on the list of focal points, manufacturing has a lot more to gain than this alone. Below is a brief look at the numerous advantages portable measurement devices have brought to the manufacturing industry.

- Flexibility as to where measurements are taken on the shop floor

- Unbeatable cost efficiency that clearly trumps traditional methods

- Increased productivity with plenty of data-backed examples to prove it

- Improved accuracy of measurements over hand tools

Not only does this technology make the job easier, but it can also create a safer and more profitable working environment. However, manufacturers are compelled to keep their eyes set on the prize, which is efficiency.

Boosting Manufacturing Efficiency Through Portable Measurement

From in-process inspections to quicker setup times and reporting, portable measurement offers efficiency levels that can't be matched. Couple this with human direction, and you will have a pretty good system.

This reality has been made possible by handheld CMMs, as faster inspection leads to better end results for businesses and consumers. Better yet, this technology's portability allows it to be applied to essentially every stage of the manufacturing process.

Any time a measurement is needed, the portable CMM can do the job. This increases efficiency without compromising the safety or careers of those on the floor. It is the perfect blend of automation, as it empowers employees to keep operations as streamlined as possible.

Why Portable Measurement is a Game-Changer for Modern Manufacturers

It's evident that portable measurement devices are improving many aspects of manufacturing processes, but to what extent? Every technology has its limits, but CMMs offer much more than a completed final inspection. They make way for innovations, technology, products, and manufacturing processes that benefit the end user and businesses alike.

It goes without saying that manufacturers benefit as well, as it leads to optimized business growth, brand awareness, and longevity in the market. Many business owners see this as a second wind because manufacturing was long overdue for such innovations.

There is always room for improvement, as this is just the beginning of CMM technology. Although its feats are amazing, to say the least, technology has a way of evolving at a surprisingly rapid rate.

KEYENCE’s Portable CMMs

Utilizing extensive in-house and external research, KEYENCE has spent years developing modern technology solutions in the manufacturing industry. We aim to lead with the most efficient and accurate measurement tools and guide manufacturers into the new age of manufacturing and quality control processes.

Our portable CMMs, the XM Series, and WM Series deliver unparalleled accuracy and adaptability in measurements, data reporting, and quality control efficiency.

If you’re looking for ways to improve your manufacturing processes from start to finish, contact us to see how we can help.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.

Brochure for the WM-6000 series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

![WM-6000 series Measurement / Application Examples [System Versatility Examples]](/img/asset/AS_116820_L.jpg)