Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

What is Anti-Static ESD Testing and Why is It Important?

Key Takeaways

- Anti-static ESD testing prevents immediate and latent electronic failures by verifying static control measures.

- Human contact, triboelectric charging, and insulated surfaces commonly generate damaging ESD events.

- Two testing levels: system-level (IEC 61000-4-2 contact/air discharge) and component-level (HBM, MM, CDM).

- Regular, documented testing ensures compliance with IEC 61000-4-2, ANSI/ESD S20.20, ISO 10605.

Electrostatic discharge (ESD) may be invisible, but its impact on electronics is immediate and often irreversible. In production environments where even minor faults can lead to costly failures, anti-static ESD testing serves as the first line of defense, verifying that control measures are in place, functioning properly, and ready to prevent damage before it occurs.

The Essential Role of Anti-Static ESD Testing in Electronics Manufacturing

Anti-static ESD testing is a non-negotiable requirement for maintaining the integrity of electronic assemblies. A single uncontrolled discharge, often imperceptible, can quietly damage circuit-level components, resulting in failures that may not surface until days or months later. In manufacturing environments, those failures translate to higher return rates, unnecessary rework, and real risks to product reliability. Testing helps prevent these losses from becoming routine; it protects the assembly process, confirms environmental controls are working, and helps organizations spot vulnerabilities before product quality is compromised.

While workplace safety and process documentation play their part, what matters most is the ability to identify, control, and respond to ESD threats as they occur. Testing is what makes that level of vigilance possible. It validates the entire static control program from grounding systems and protective garments to EPA workstation integrity. Without testing, static mitigation is guesswork, and the importance of ESD testing becomes clear only after product failures occur.

We’re here to provide you with more details.

Reach out today!

Basics of Electrostatic Discharge (ESD)

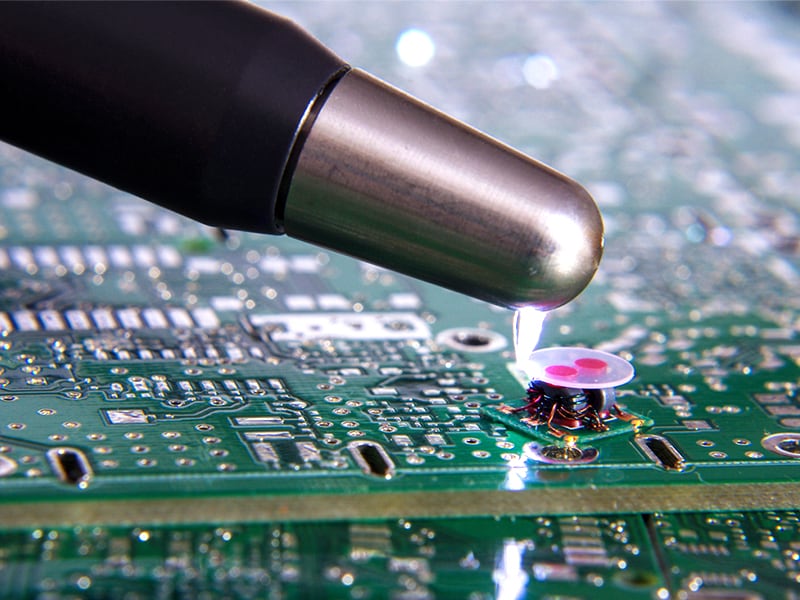

Static buildup can occur from everyday motion, tool contact, or material handling. When released, that energy can instantly damage sensitive electronics and lead to long-term product instability.

What Causes ESD?

Electrostatic discharge occurs when two objects with differing charge levels equalize through a rapid transfer of energy. This energy can come from the contact and separation of materials, triboelectric charging, induction, or simply the buildup of voltage on insulated surfaces. In practice, this means that a charged person touching a PCB, a powered component interacting with another, or even a tool making contact with a connector can release an ESD event.

Human contact is one of the most common sources of discharge. Even walking across a floor with improper footwear or handling a tray without grounding can build thousands of volts of potential energy, enough to instantly damage microelectronics. In high-mix environments, these events can happen repeatedly unless controls are actively monitored.

Consequences of Unchecked ESD

The cost of ignoring ESD isn’t limited to catastrophic damage, as latent failures are just as dangerous, often more so. A device might pass functional tests, ship to a customer, and then degrade in the field. These intermittent or delayed failures increase warranty claims, erode brand confidence, and inflate support costs. In sectors like medical devices or automotive systems, even minor degradation can trigger significant liability.

Beyond electronics failure, discharges also pose a risk in areas with flammable materials or cleanrooms, where a spark can create safety hazards or contamination. Static control programs without testing leave these systems vulnerable, unable to verify that grounding paths or shielding procedures remain effective under real-world conditions.

Discover more about this product.

Click here to book your demo.

Overview of ESD Testing Procedures

Anti-static ESD testing depends on calibrated equipment and proven methods to identify weak points and confirm that mitigation systems perform reliably under real-world conditions.

Common Testing Methods

There are two primary approaches to ESD testing: system-level and component-level.

System-level testing evaluates entire devices or assemblies in conditions that mimic real-world interaction. These include contact and air discharge methods, based on standards such as IEC 61000-4-2. Contact discharge provides consistency by applying current directly to the unit under test (UUT), while air discharge simulates field-like conditions using a small air gap between the simulator and the UUT.

Component-level testing examines individual elements like ICs or connectors, using models such as the Human Body Model (HBM), Machine Model (MM), and Charged Device Model (CDM). These simulations determine the voltage threshold at which components fail, helping engineers define safe handling limits.

System-level testing assesses how an entire product responds to discharge in its intended operating environment. Component-level testing helps set material requirements and manufacturing parameters.

Equipment Used in ESD Testing

A typical ESD testing setup includes simulators, discharge tips, and RC networks tailored to the appropriate standard. Simulators are configured to deliver both polarities, adjustable voltage levels, and specified waveforms with precise rise and fall times.

Workplace testing equipment, on the other hand, is designed to verify control systems, wrist straps, heel grounders, conductive flooring, and EPA surfaces. Resistance meters and continuous monitors provide ongoing visibility, sounding alerts when static protection degrades.

KEYENCE static ionizers, such as the SJ-E, SJ-LM, and SJ-LG Series, can also play a role in verification. These ionizers neutralize surface charges across work areas while providing visibility into performance through remote control functions. Teams can monitor ion balance in real time and quickly identify when static levels begin to drift. By linking monitoring tools directly to the production environment, operators can confirm whether passive ESD control measures are holding up under actual working conditions.

Importance of Regular ESD Testing

ESD controls aren’t one-and-done. Without consistent testing, even well-designed systems can drift out of spec, exposing components to preventable damage and compliance failures. Materials degrade. Ground paths break. Operators change routines. Regular testing keeps the system honest.

More importantly, consistent testing minimizes preventable yield loss. When grounding paths fail or materials lose conductivity, product quality suffers. Periodic testing catches these failures before they leave the production line.

Frequent testing also supports audit-readiness. Many industries, especially those regulated under medical or automotive guidelines, mandate documentation proving consistent ESD control. Without a record of verification, even strong static protection measures carry limited credibility.

Compliance with Standards

Routine ESD testing is the foundation for meeting international standards, including IEC 61000-4-2, ANSI/ESD S20.20, and ISO 10605. These frameworks define how to measure charge levels and verify device immunity under both normal and extreme conditions.

Real-world conditions, like shifting humidity, aging equipment, or changes to workstations, can weaken static control over time. Static control standards require more than a one-time implementation. Regular calibration and retesting account for those variables, confirming that protection systems are still doing their job long after they’re installed. It also helps catch process drift early, before it affects product quality or operator safety.

Don’t let ESD damage disrupt your line! Ensure product reliability with KEYENCE ESD testing solutions.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Often Should ESD Testing Be Performed?

Daily checks for wrist straps and footwear are common. Surfaces, ionizers, and equipment should be tested on a regular schedule based on risk and industry standards.

What is the Difference Between Anti-Static and ESD-Safe?

Anti-static materials slow the buildup of static charge, while ESD protection materials actively prevent discharge by providing a controlled path to ground, reducing the risk of damaging sensitive components.

Can ESD Testing Be Automated?

Yes. Continuous monitoring systems can track grounding performance, static levels, and ionizer output in real time, reducing the need for manual checks and improving overall visibility.

What Types of Equipment Require ESD Testing?

Any item involved in handling or assembling sensitive electronics (including work surfaces, mats, wrist straps, ionizers, garments, and packaging) should be tested to confirm ESD control compliance.

What are the Consequences of Non-Compliance with ESD Standards?

Failing to meet ESD compliance requirements can result in field failures, audit violations, and contract penalties, particularly in regulated industries.

We’re here to provide you with more details.

Reach out today!