Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

Vision Systems for the Commodities Industry

Vision systems are often used in the commodities industry, which encompasses metals, plastic, energy, agricultural products, and more.

KEYENCE's vision systems for the commodities industry utilize state-of-the-art cameras, lighting, and image-processing algorithms to perform tasks such as inspection, measurement, and tracking. These systems are designed to operate in challenging industrial environments and provide highly accurate and reliable results.

Simultaneous reading and vision inspection

Auto-teach inspection tool

Multi-camera hardware

We’re here to provide you with more details.

Reach out today!

Applications in the Commodities Industry

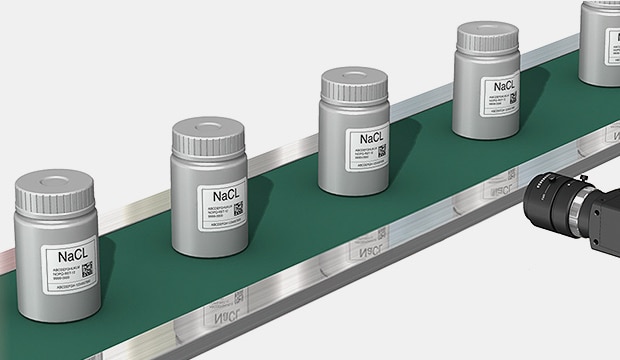

Detecting Misaligned Labels

Misaligned labels due to shrinkage or improper application can disrupt inventory tracking and logistics. KEYENCE's vision systems detect and alert operators to prevent potential issues.

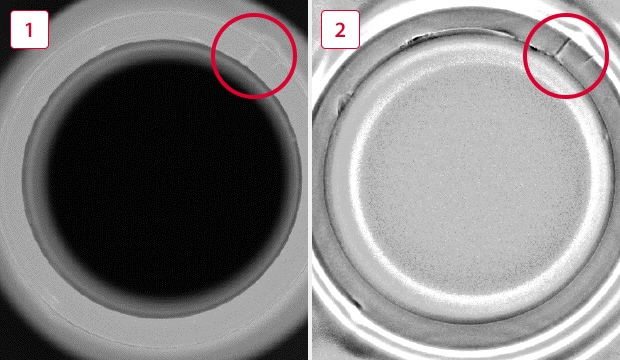

Detecting Chipping of a Bottle Mouth

Damaged bottle mouths can lead to contamination and affect product quality. High-resolution cameras capture detailed images of bottle mouths, allowing for precise detection of any chips or defects.

-

1Normal lighting

-

2LumiTraxTM lighting

Inspecting the Appearance of Aluminum Can Bottoms

Damage or contamination during the production process can occur with aluminum cans.

KEYENCE's vision systems detect defects like dents and scratches on aluminum cans using advanced algorithms.

Inspecting the Appearance of Media Disks

KEYENCE's vision systems ensure media disks meet quality standards by detecting defects such as scratches or incorrect labeling, guaranteeing delivery of only high-quality products.

Discover more about this product.

Click here to book your demo.

FAQs About Vision Systems in the Commodities Industry

What Are the Benefits of Using Vision Systems in the Commodities Industry?

Thanks to their accuracy and reliability, vision systems offer many benefits, such as enhanced quality control, increased production efficiency and productivity, improved traceability, waste reduction and associated costs, and support for compliance with regulatory standards.

What Types of Vision Systems Are Commonly Used in Commodities Manufacturing?

Vision systems in the commodities industry use 2D, 3D, and thermal imaging, as well as multispectral and glare-reducing lighting techniques to catch hard-to-see defects.

What Challenges Do Vision Systems Help Address in the Commodities Industry?

Vision systems for the commodities industry address various challenges, such as maintaining consistent quality standards, identifying bottlenecks and inefficiencies in the production process, enhancing traceability throughout the supply chain, and reducing the risks associated with compliance issues.

How Do Vision Systems Support Traceability and Compliance Requirements in the Commodities Industry?

Vision systems for commodities enhance traceability by capturing detailed records of each product that goes through the supply chain and automating the detection and documentation of quality parameters and inspection results. This allows for a faster response to quality and compliance issues and facilitates faster elimination and removal.

What Are the Primary Considerations When Selecting Vision Systems for the Commodities Industry?

The primary considerations when selecting vision systems in the commodities industry are tailored to the application needs for resolution, lighting, and specific defects they are programmed to detect. Additionally, they must have the ability to integrate with your current systems and maintain cost-effectiveness.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace