Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

Vision Systems for the Machine Tool Industry

Explore our Machine Tool Industry-focused vision systems designed to streamline tool wear monitoring, dimensional measurements and surface finish detections.

Vision systems, made up of special types of cameras, lenses, and processing software, serve as “eyes” for machines, enabling them to interpret the world around them, analyze, and make decisions based on visual inputs.

KEYENCE has revolutionized the manufacturing industry with its innovative range of vision systems. By incorporating advanced vision technology into machine tools, KEYENCE has helped businesses achieve higher levels of precision, reliability, and productivity.

The VS Series is an AI vision system for the machine tool industry that analyzes and interprets sophisticated visual data. It streamlines inspections, boosting efficiency while saving time and resources.

Applications of Machine Tool Vision Systems

Tool Wear Monitoring and Inspection

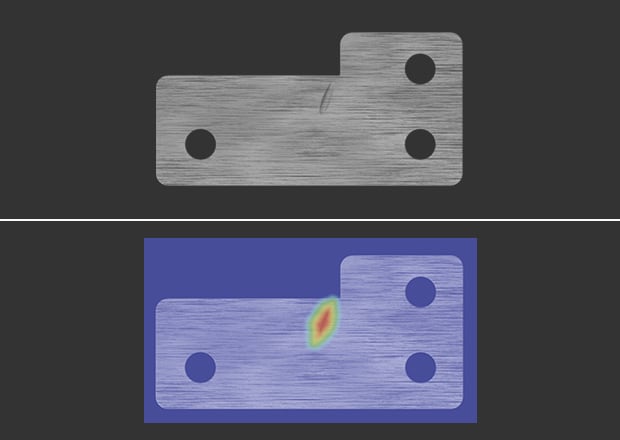

High-resolution cameras and advanced image-processing algorithms detect the subtlest changes in tool conditions that might not be visible to the human eye, preventing defective parts, replacement costs, and machine downtime.

Dimensional Measurement in Machining

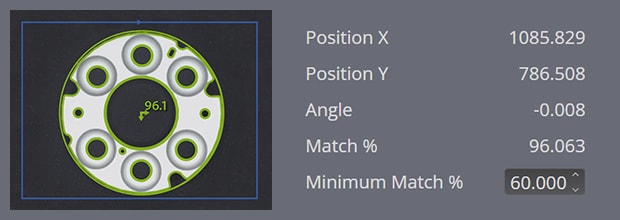

Vision systems for the machine tool industry ensure dimensional precision and a non-contact means of measuring the dimensions of machine tools in real time, ensuring the workpiece is produced within specified tolerances.

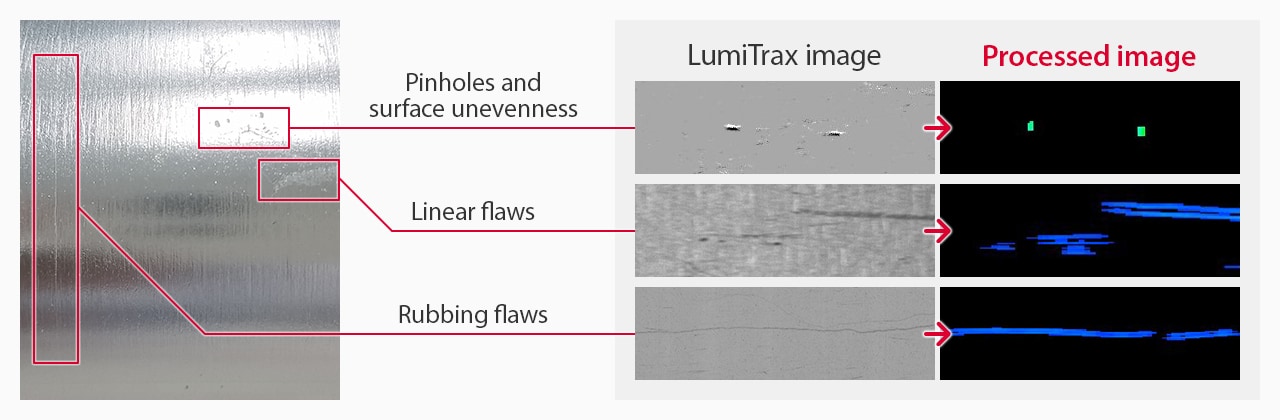

Surface Finish Inspection in Machine Tool Processes

Sophisticated imaging and processing software analyzes the patterns and textures of a particular surface and provides a detailed assessment of surface quality in a fraction of the time required in traditional machine tool defect inspections.

We’re here to provide you with more details.

Reach out today!

Introducing Our AI-Powered Vision System for the Machine Tool Industry

The machine tool industry is evolving with AI and advanced vision systems, transforming manufacturing by improving accuracy and efficiency. Introducing the VS Series, an AI-powered smart camera designed for modern manufacturing challenges. With user-friendly software and adaptive learning, it enables fast, accurate AI vision inspections in the machine tool industry.

Here are some of its core features:

- Accurate Inspection: Detects defects and deviations in real-time during production.

- Adaptive Learning: Continuously enhances accuracy by adapting to new data and recognizing evolving patterns.

- Optical Zoom: Mechanical zoom lenses enable optical zooming without any loss of image resolution.

- Ease-of-use: The interface is intuitive, well-organized, and straightforward, offering flexibility and ease of use.

Upgrade inspections with the VS Series, AI-powered vision systems for unmatched precision and efficiency. Contact us today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Vision Systems in the Machine Tool Industry

What Are the Benefits of Using Vision Systems for the Machine Tool Industry?

Thanks to their exceptional precision, vision systems for the machine tool industry offer a whole range of advantages beneficial to the production process. This includes enhanced precision and quality, increased efficiency and productivity, reduced costs, improved safety, and support for complex manufacturing.

What Types of Vision Systems Are Commonly Used in Machine Tool Manufacturing?

Vision systems for the machine tool industry are often composed of different types of advanced imaging systems, such as 2D vision systems, 3D vision systems, infrared and thermal imaging systems, and hyperspectral and multispectral imaging systems.

What Challenges Do Vision Systems Help Address in the Machine Tool Industry?

Machine tool vision systems address a range of challenges associated with the machine tool industry. They enhance quality control, optimize various manufacturing processes, monitor and report on the physical condition of cutting tools, and facilitate the precision necessary for manufacturing complex parts and components.

How Do Vision Systems Support Traceability and Compliance Requirements in the Machine Tool Industry?

Machine tool vision inspection systems support traceability and compliance in the machine tools industry by documenting production processes and enabling part and batch identification, which helps quality assurance and makes supply chain and inventory management easier.

What Are the Primary Considerations When Selecting Vision Systems for the Machine Tool Industry?

Selecting a vision system for the machine tool industry depends on the specifics of your production process and the application of said vision systems. Factors you should consider are resolution and accuracy requirements, environmental conditions, integration with existing systems, and cost and ROI.

Related Downloads

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace