Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

Vision Systems for the Food and Beverage Packaging Industry

Explore our food and beverage packaging industry-focused vision systems designed to streamline packaging inspection, label verification, and quality control.

The food and beverage packaging industry relies on packaging that can often times be easily deformed or damaged during production. KEYENCE’s machine vision for the food and beverage packaging industry is ideally suited for quality assurance in packaging operations, as they ensure your packaging is free of tears, burrs, or surface imperfections.

The KEYENCE VS Series is an AI-powered vision system that improves food and beverage packaging by utilizing quality checks, detecting defects immediately, and ensuring compliance, enhancing efficiency and reducing waste.

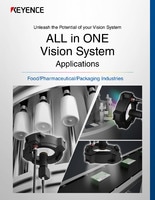

Food tray inspection

Presence inspection for seasoning packets

Juice box straw inspection

Pasta contamination and hole inspections

Label alignment inspection

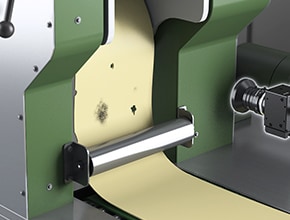

Chocolate bar inspections

Inspection for foreign particles in jelly after filling

Can side appearance inspection

Applications of Food Vision Systems

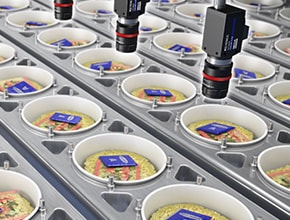

Packaging Inspection for Food Safety

Damaged packaging may introduce foreign particles that may contaminate your product, so it’s important to inspect the product before and after sealing. Utilizing on multi-spectrum lighting, the CV-X Series sensor can detect and extract slight color variations to detect only defective products.

Quality Control in Packaging Processes

Food vision systems verify the presence or absence of items and components in packaging, ensuring the completeness of packaged products before they’re shipped to consumers. For example, the VS Series Camera with built-in AI allows for stable imaging, even for targets in various states, including hot melts.

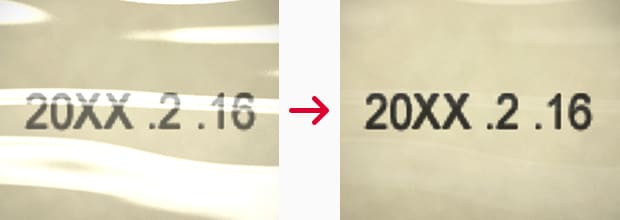

Printed character inspection on a film surface

Label Verification on Food and Beverage Products

The gloss and background color of the target packaging can cause difficulties in text and marking identification in conventional inspections. However, the CV-X Series' LumitraxTM lighting mode helps accurately detect and extract texts and markings, even from uneven and glossy surfaces, resulting in stable, accurate, and reliable inspections.

We’re here to provide you with more details.

Reach out today!

Introducing Our AI-Powered Vision System for the Food and Beverage Industry

Elevate your quality control processes with our AI-driven vision system, specifically engineered for the food and beverage industry. Leveraging state-of-the-art technology, our system enhances packaging inspections, ensuring compliance and safety while optimizing efficiency. Experience unmatched precision that empowers you to deliver superior products to your customers, all while minimizing waste and reducing operational costs.

Core Features:

- AI-Powered Analysis: Uses advanced auto-focus algorithms to read codes and detect flaws with high accuracy.

- Multi-Format Compatibility: Adapts easily to various packaging types and sizes without sacrificing performance.

- Optical Zoom: Mechanical zoom lenses allow for optical zoom with no loss in resolution.

- Ease-of-use: The interface is simple, organized, and easy to understand, making it flexible and capable of use.

Discover how our AI-powered vision systems for food and beverage manufacturing can elevate your packaging quality. Contact us today for a consultation!

Applications and Examples

FAQs About Vision Systems in the Food and Beverage Packaging Industry

What Are the Benefits of Using Vision Systems for the Food and Beverage Packaging Industry?

Vision systems for food and beverage packaging have several benefits that lead to customer satisfaction and brand protection, including:

- Precise inspections and consistency for enhanced quality control

- Speed and automation integrations for increased efficiency and productivity

- Reduced downtime

- Early defect detection for better waste reduction

- Improved traceability and compliance

What Types of Vision Systems Are Commonly Used in Food and Beverage Packaging Manufacturing?

Vision systems for food and beverage packaging rely on several imaging technologies, each suited to a specific application. This includes:

- 2D and 3D laser sensors

- Stereoscopic cameras

- Infrared and thermal imaging cameras

- Hyperspectral and multispectral imaging systems

- Optical character recognition

- Optical character verification

- Color vision systems

What Challenges Do Vision Systems Help Address in the Food and Beverage Packaging Industry?

Food vision inspection systems address several challenges within the industry. This includes the detection of a wide range of defects:

- Misalignments

- Incorrect labeling

- Improper sealing

- Packaging damage

They also ensure that the food/beverage containers are filled to the correct levels and provide an autonomous, high-speed inspection, which not only boosts efficiency, but also leads to waste reduction.

How Do Vision Systems Support Traceability and Compliance Requirements in the Food and Beverage Packaging Industry?

Vision systems for food and beverage packaging also play a rather crucial role in supporting traceability and compliance requirements by ensuring product tracking through the supply chain. These systems read barcodes and QR codes printed on the packaging, enable more efficient inventory and storage management, verify that the labels contain all the necessary information, and inspect the integrity of the packaging itself.

What Are the Primary Considerations When Selecting Vision Systems for the Food and Beverage Packaging Industry?

Selecting the right vision systems for food and beverage packaging operations mostly depends on the application itself. Different vision systems are better suited to specific materials, shapes, and sizes, which plays a crucial role in the selection process. The same applies to quality assurance and inspection requirements. However, you should also consider the ease of use, integrability, and the initial costs.

What Are the Applications for Vision Systems in the Food and Beverage Packaging Industry?

Vision systems for food and beverage packaging have found their use in numerous applications crucial to the production process, such as quality control, label and packaging verification, product and packaging safety, sorting and classification, and traceability and compliance.

How Do Vision Systems Effectively Detect Contaminants or Foreign Objects in Food and Beverage Packaging?

Vision systems detect contaminants and foreign objects in food and beverages by using a combination of advanced imaging technologies, machine learning, and AI algorithms. These systems are specifically designed to identify materials and objects that don’t belong inside a particular product, ensuring the safety and quality of products before they reach the end-consumer.

What Are the Unique Features of Vision Systems for the Food and Beverage Industry That Enable Precise Defect Detection?

It depends on the type of vision system used. These features typically involve the use of high-resolution cameras, sensors, advanced imaging techniques, artificial intelligence and machine learning, and real-time processing and feedback.

Related Downloads

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace