Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

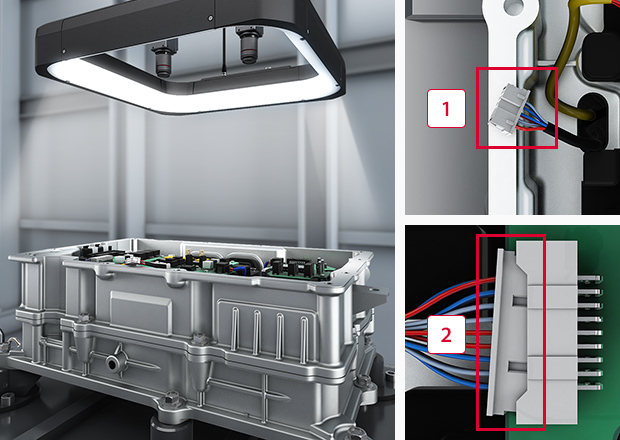

Vision Systems for the Electric Vehicle Industry

Explore our Electric Vehicle industry-focused vision systems designed for battery inspection, inverter inspection, and overall quality control.

The electric vehicle manufacturing industry has unique challenges, including the assembly of high-voltage battery packs, electric motors, and intricate electronic control units necessary for the electric vehicle's operation. Vision systems for the electric vehicle industry address this by enabling high-precision manufacturing and precise quality assurance throughout the manufacturing process.

KEYENCE offers cutting-edge vision systems with advanced features, such as high-speed data processing, high-resolution imaging capabilities, and customizable inspection algorithms to meet the unique demands of electric vehicle production.

-

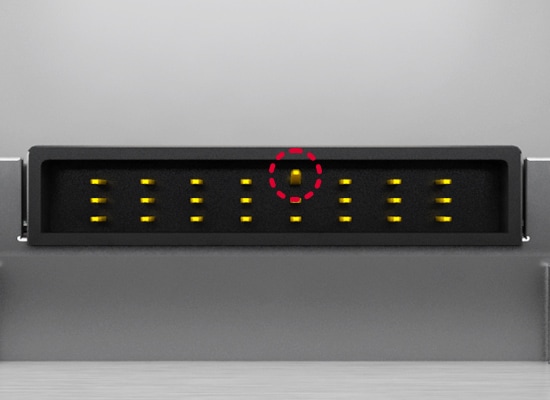

1Obstruction

-

2Engagement failure

The VS Series uses AI powered analysis and an intuitive interface to enhance inspection efficiency on assembly lines. Its adaptable design enables quick deployment, real-time quality control, and data-driven decisions.

Vision System Applications for Electric Vehicles

Pre-welding insulation film inspection

Battery Assembly Verification

Electric vehicle vision systems can detect misalignment and other anomalies that occur during the assembly process, such as improper welding spots and inconsistent spacing between battery cells.

Normal image

Protruding insulation film.

LumiTraxTM image

Bent connector terminal inspection

Quality Inspection for Electric Vehicle Components

Vision systems for the electric vehicle industry offer sophisticated quality assurance and quality control inspections through high-resolution imaging analysis.

Acceptable product

Defective product

Bent terminal.

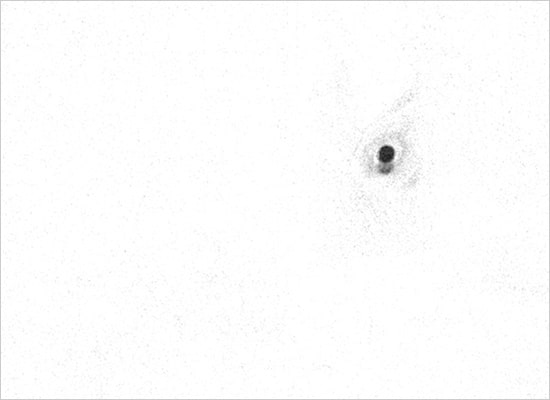

Appearance inspection of positive and negative electrode materials

Surface Defect Detection in EV Manufacturing

Identify a wide range of surface imperfections that can compromise the vehicle's safety and performance by scanning the surfaces at various stages of production and manufacturing.

Conventional image

Foreign particle.

Processed image

We’re here to provide you with more details.

Reach out today!

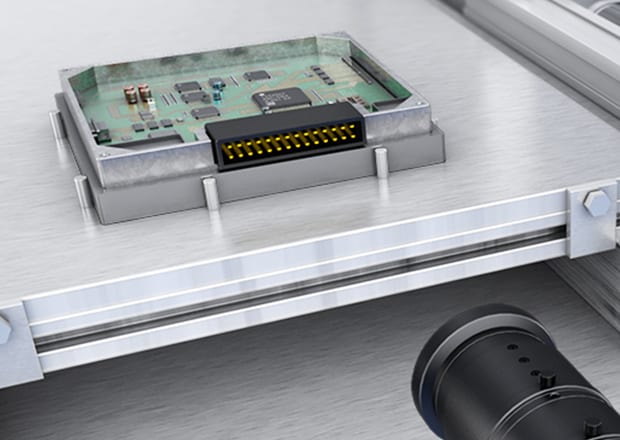

Introducing Our AI-Powered Vision System for the Electric Vehicle Industry

As demand for electric vehicles grows, efficient quality control is more critical than ever. Our VS Series AI vision system for the electric vehicle industry offers a transformative solution. Using advanced AI algorithms, our smart camera performs rapid, precise AI vision inspections in the electric vehicle industry. This is typical of key EV components like batteries, motors, and charging systems. Its high-speed processing detects even the smallest defects, ensuring every vehicle’s performance and reliability.

Core Features:

- Ease-of-use: The interface is intuitive, well-organized, and user-friendly, offering flexibility and ease of use.

- Multi-Format Compatibility: Easily adapts to a wide range of packaging types and sizes while maintaining high performance.

- AI-Powered Analysis: Utilizes advanced auto-focus algorithms to accurately read codes and identify flaws with precision.

- Optical Zoom: Mechanical zoom lenses enable optical zoom without any loss in resolution.

Learn how our AI vision systems for the electric vehicle industry can transform your production line. Contact us today to schedule a consultation.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Vision Systems in the Electric Vehicle Industry

What Are the Benefits of Using Vision Systems in the Electric Vehicle Industry?

The integration of electric vehicle vision inspection systems brings plenty of benefits that provide enhanced quality control, increased manufacturing efficiency, safety improvements, cost reductions, and support for automated and autonomous features.

What Types of Vision Systems Are Commonly Used in Electric Vehicle Manufacturing?

The EV manufacturing process employs several types of electric vehicle vision systems, including 2D vision systems, 3D vision systems, infrared and thermal imaging, and hyperspectral imaging.

What Challenges Do Vision Systems Help Address in the Electric Vehicle Industry?

Vision systems for the electric vehicle industry help overcome several industry-specific challenges, such as complex assembly verification, battery safety and performance, high-volume production with quality, and adaptation to new materials and technologies.

How Do Vision Systems Support Traceability and Compliance Requirements in the Electric Vehicle Industry?

Besides immensely benefiting the EV industry, electric vehicle defect inspection supports traceability by documenting inspections and associating them with specific components or batches, adhering to regulatory requirements.

What Are the Primary Considerations When Selecting Vision Systems for the Electric Vehicle Industry?

When choosing vision systems for the electric vehicle industry, several factors should be considered, including resolution and accuracy needs, the system's integration capability, environmental conditions, and associated costs.

Related Downloads

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace