Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

AI-Driven Vision-Guided Robotics for Enhanced Industrial Automation

As manufacturing shifts toward a greater mix of products, higher speeds, and tighter tolerances, vision-guided robotics has reshaped factory automation. These modern vision systems for robotics give production teams the tools required to handle it all without slowing down. AI robotics vision systems are improved now that robots can identify, interpret, and manipulate, forming the foundation for dependable vision-guided robotic automation in real-world conditions. These systems also help teams adapt to changing product schedules and more frequent design updates without major workflow disruption.

In the following, we explore the key features of these innovative systems, their applications across industries, and how they are transforming the landscape of robotics and automation.

We’re here to provide you with more details.

Reach out today!

What Is Vision-Guided Robotics?

Vision-guided robotics integrates imaging hardware, advanced software tools, and robot motion control into a unified workflow, so, instead of relying on fixed positions or rigid fixturing, a Vision-guided robotics setup uses cameras to identify part shape, orientation, and location at the moment of action. This approach supports Automated robotic guidance systems by giving robots the data needed to react to shifts in part presentation, surface differences, or orientation changes. The result is a system that handles complex assemblies, mixed production, and unpredictable layouts with steady performance across long runs.

How AI-Powered Vision Enhances Robotic Precision

AI robotics vision systems introduce greater stability when lighting, contrast, or surface conditions vary. Machine learning tools can interpret more of each image, allowing robots to locate details that standard rule-based imaging might miss. Subtle edges, reflective parts, and flexible materials become easier to identify, which keeps guidance reliable during high-speed tasks.

When paired with 2D and 3D vision systems for robotics, AI-driven inspection and guidance deliver consistent results even when parts differ in color, thickness, or texture. This supports high-throughput production lines that depend on accurate pick points, precise tool alignment, or reliable inspection before and after handling.

Key Features of Keyence Vision-Guided Robotics

KEYENCE vision-guided robotic automation combines imaging performance with fast processing and straightforward integration. The VS Series combines high-speed inspection and robot guidance on a single platform, reducing setup time while supporting multiple tasks. High-resolution cameras deliver clean images across wide fields of view, and built-in 3D tools detect part height and depth for accurate gripping, stacking, and sorting.

Get detailed information on our products by downloading our catalog.

View Catalog

Applications of Vision-Guided Robotics in Manufacturing

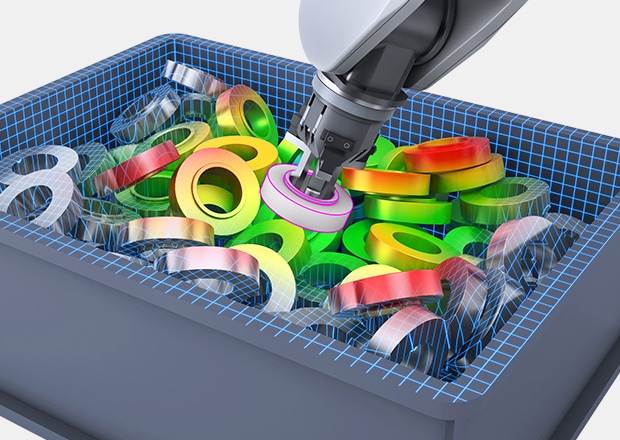

Vision-guided robotics appears across many production lines because it handles variation without slowing the cell. In assembly, visual feedback helps a robot position parts that shift slightly from cycle to cycle. For bin picking, 2D and 3D tools read depth and orientation so mixed parts can be pulled from a tote with steady precision. Material handling cells also benefit when parts drift on conveyors, since guidance adjusts the robot’s approach in real time. Inspection tasks use the same vision data to verify features or placement before products move downstream. These capabilities support electronics, automotive components, packaging, and other high-mix operations.

Vision-Based Navigation for Robots

KEYENCE’s CV-X Series offers unmatched detection performance and usability, allowing automatic calibration from the vision system to the robot. This leads to a significant reduction in labor hours for creating robot programs, improves cycle times, eliminates waste from poor designs, and offers a dramatic improvement in success rate and unparalleled safety.

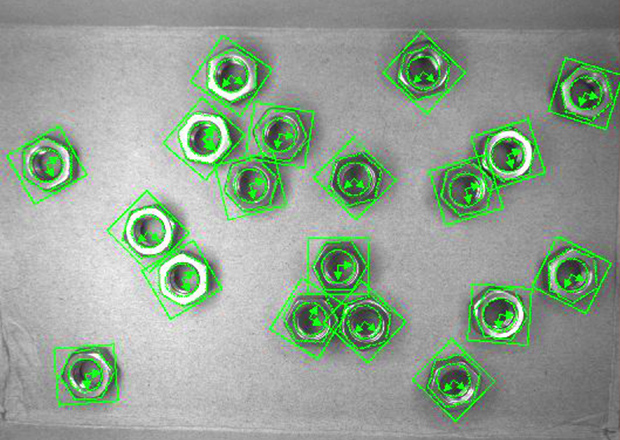

Bin-Picking

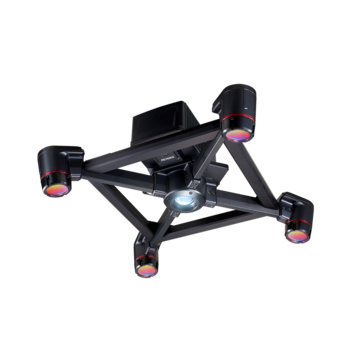

KEYENCE developed 3D search algorithms and optical systems that deliver high precision and high-speed performance for bin-picking applications. These systems rely on four separate 3D cameras to create a 3D image free of blind spots, providing the robot with optimum detection results. These are further backed by functions such as HDR image processing and multiple reflection suppression.

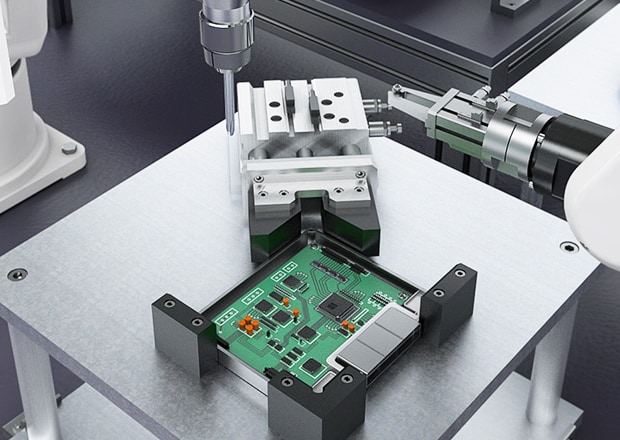

Quality Control in Robotic Manufacturing Processes

Many industrial assembly lines rely on robots for heavy lifting and other tasks. These robots rely on precise machine vision systems to perform navigation and object recognition and avoid collisions with other robots or humans during operations, ensuring the quality of the end product.

Object Recognition and Handling in Robotics

Machine vision systems for the robotics industry use a combination of hardware, cameras and sensors with integrated software solutions, such as machine learning and artificial intelligence algorithms, to recognize objects and handle them in a way that provides efficient and safe operation.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Vision-Guided Robotics

What Are the Benefits of Using Vision Systems for Robotic Guidance?

Benefits of using a machine vision system for robotic guidance include:

- Enhanced accuracy and precision

- Improved versatility

- Better adaptability to changes in the environment

- Enhanced object recognition

- Reduced product damage

- Safety improvements

What Types of Vision Systems Are Commonly Used in the Robotics Industry?

Vision systems for the robotics industry use a variety of imaging technologies along with advanced artificial intelligence and machine learning algorithms to operate. This includes 2D and 3D scanners and camera systems, as well as a plethora of sensors to derive environmental and target data.

What Challenges Do Vision Systems Help Address in the Robotics Industry?

Vision systems for the robotics industry help address various issues, most of which are related to object recognition and classification, spatial navigation and obstacle avoidance, precision and accuracy in task execution, and adaptability to variable tasks and environment changes—these qualities make vision systems great for quality control.

How Do Vision Systems Support Traceability and Compliance Requirements in the Robotics Industry?

Many industries, including manufacturing and commerce, rely on product traceability for logistics and compliance purposes. Vision systems associated with pick-and-place robots can track components, products, and processes, ensuring operational activities meet the required standards.

What Are the Primary Considerations When Selecting Vision Systems for the Robotics Industry?

Selecting an appropriate robot vision system for your particular application is application-dependent and involves considering factors like resolution and image quality, processing speed, field of view and depth of field, integrability with your existing system, and, of course, costs.

What Are the Steps in Implementing Vision Systems for Robotics?

Implementing an adequate vision system that satisfies your application requirements effectively starts by defining the requirements themselves, followed by the selection of the appropriate vision system and choosing the right hardware and software solutions.

What Challenges Does Vision-Guided Robotics Address?

Vision-guided robotics addresses a wide range of challenges associated with complex object manipulation, dynamic environment navigation, quality control, and inspection, as well as the precision requirements for placement and assembly tasks.

What Are The Key Elements of a KEYENCE Robotic Vision System?

The key elements of KEYENCE’s robotic vision systems include: a 3D vision-guided robotics controller, a 3D vision-guided robotics camera input unit, a dedicated 3D vision-guided robotics camera, and 2D area camera options. All these systems use an automatic calibration between the vision system and the robot.

What Applications Can Benefit From a Vision-Guided Robotics Solution?

Applications that would benefit the most from a vision-guided robotics solution are industry-specific. For example, manufacturing and assembly industries would benefit from precision assembly, while quality control would benefit from automated defect detection and dimensional verifications. The list of examples isn’t short, and any industry that would benefit from robotic automation would also benefit from vision-guided robotics solutions.

What Are the Advantages of Using Vision-Guided Robotics Over Traditional Robotic Systems?

Vision-guided robotics provides real-time positional data, which reduces dependence on fixed setups. This supports greater accuracy and steady performance when parts vary in location or presentation.

How Does AI Enhance the Performance of Vision-Guided Robotics?

AI helps strengthen detection tools by interpreting more features within each image. This reduces missed edges, supports better part recognition, and stabilizes guidance when surfaces or lighting vary. The result is a system that adapts smoothly to new products or presentation changes.

Can Vision-Guided Robotics Be Used With Collaborative Robots?

Yes. Vision data helps collaborative robots track part position and maintain predictable motion paths, supporting smooth operation in shared workspaces.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace