Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

Essential Hardware Components of Machine Vision Systems

Machine vision allows machines to see and analyze their surroundings with cameras, sensors, and advanced algorithms. From optimizing factory production to revolutionizing healthcare, enhancing security, and making smarter cars, machine vision systems are changing how we work and live.

At the core, hardware components of machine vision systems work cohesively to capture, process, and deliver visual data with pinpoint precision.

Key Components of a Machine Vision System

From spotting flaws on the assembly line to diagnosing issues with pixel-perfect accuracy, the components of machine vision systems work together to keep things running efficiently.

Hardware that supports inspection stability

Image Sensors: CCD vs. CMOS Sensors

The image sensor is the main component of machine vision systems, turning light into electrical signals in an instant. Machine vision relies on different types of sensors to bring images to life, with charge-coupled devices (CCD) and complementary metal-oxide-semiconductor (CMOS) sensors leading the way.

-

1Built-in dedicated illumination control circuit

-

2Ultra, high-speed cmos camera and dedicated control circuit

-

3Lighting equipped with 8 high-brightness LEDs of different wavelengths

-

4Photodiode and real-time intensity control circuit

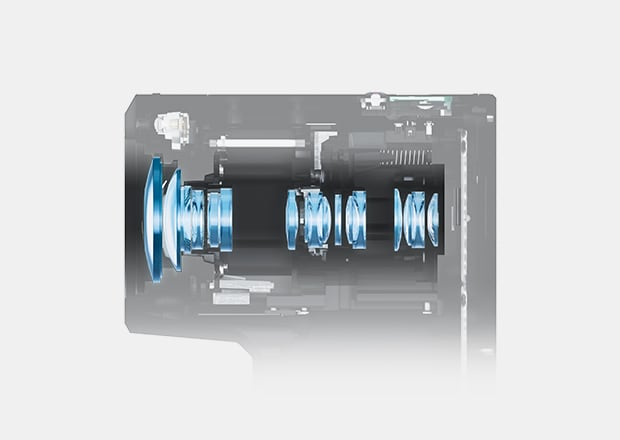

Machine Vision Lenses

Machine vision lenses capture light and turn it into sharp images for precise data analysis.

Manual lenses are perfect for fixed environments where the subject stays the same. But when frequent adjustments are needed, they can quickly become a hassle, eating up time and effort.

Autofocus lenses revolutionized photography by making focusing effortless. Using advanced sensors, these lenses detect changes in distance or contrast and adjust focus automatically. Perfect for capturing fast-moving action or managing multiple cameras at once, they deliver sharp, precise focus with ease, even in the most dynamic situations.

Liquid lenses use electrically-controlled liquid to change shape for improved focus. They deliver lightning-fast, pinpoint accuracy while being durable enough to withstand shocks and vibrations.

Machine Vision Lightning

Effective machine vision lighting is essential for optimal system performance. LEDs are the best choice and the most widely used option for machine vision applications.

- LEDs

- LEDs (light-emitting diodes) are solid-state devices that produce light when an electrical current is applied. Their precise and consistent light output makes them ideal for machine vision systems, where accuracy and reliability are key. A major benefit of LEDs is their energy efficiency. Using far less power than traditional lighting, they cut electricity costs and reduce environmental impact, providing a practical and sustainable solution.

LED lighting combines energy efficiency, durability, and precision in one. With customizable color temps and barely a hint of heat, LEDs bring the perfect glow to every job. While the initial cost is higher than that of fluorescent or halogen lights, the long-term benefits, superior performance, reliability, and efficiency make LEDs the clear winner for advanced inspection systems.

Cameras

Machine vision system cameras are taking image quality to the next level, boasting resolutions from 0.35 to 64 megapixels. They don’t just capture details; they highlight them with precision, making even the most complex inspections feel effortless. With these cameras, inspections become more accurate, there are fewer mistakes, and results can be counted on every time. And thanks to their advanced resolution, they deliver faster performance, slashing image transfer times compared to older models. It’s time to inspect smarter, not harder!

Linescan vs. Area Cameras

In machine vision systems, choosing the right camera is key for accurate and efficient inspections. Two common options, line scan and area cameras, offer unique advantages for specific applications.

- Linescan Cameras: Linescan cameras capture images line by line, providing high-resolution imaging for extensive surfaces at high speeds. They are ideal for inspecting cylindrical objects or continuous materials in industries like printing and packaging.

- Area Cameras: Area cameras capture entire images in a single frame, making them perfect for stationary image capture and smaller objects. Their high-speed imaging and rapid frame rates are also great for dynamic inspections requiring precision and speed.

Our XG-X Vision systems offer both line scan and area cameras, with options for 2D or 3D imaging, providing customizable solutions for your needs.

Curious about our pricing?

Click here to find out more.

Meeting Machine Vision Hardware Requirements

KEYENCE machine vision hardware is built to tackle a wide range of manufacturing challenges, offering the perfect blend of versatility and performance. The VS Series delivers a complete vision solution in a compact, smart camera. Its built-in CPU eliminates the need for an external PC, slashing both costs and complexity. An intuitive interface and advanced tools like line scan technology make even the toughest inspection tasks a breeze, all while maintaining precise and reliable results.

KEYENCE offers hardware components for machine vision systems with a wide range of lenses and lighting solutions for superior image quality. Options like telecentric, macro, and zoom lenses ensure sharp, distortion-free imaging for accurate inspection results.

Ready to improve your manufacturing process? Contact us today to discover our machine vision systems, which are custom-built to meet your machine vision hardware needs.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics