Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

What are Shutter Speed and Exposure Time?

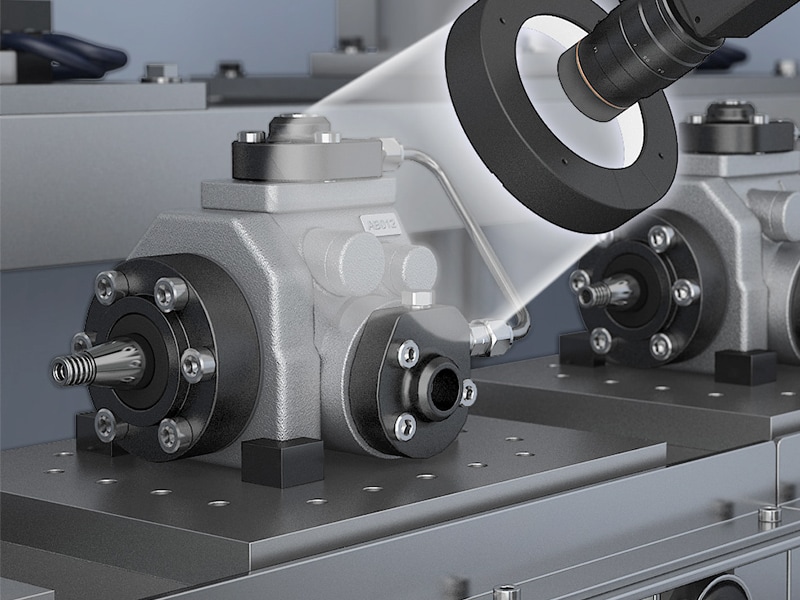

In machine vision, image clarity depends on timing. Two closely related settings—shutter speed and exposure time—determine how long light is allowed to hit a camera’s sensor during each frame. While the terms are often used interchangeably, especially in industrial imaging, the concept remains the same: exposure time controls how much light is captured and for how long. In machine vision systems, particularly in high-speed automation, shutter speed and exposure time directly affect how sharply moving parts appear and whether inspection data is accurate.

Why Do Shutter Speed and Exposure Time Matter in Machine Vision?

The exposure time determines the interval during which the sensor collects light data. In machine vision, this translates into how much detail is preserved and how clearly a moving object appears.

If the exposure time is too long relative to how fast an object moves or if the object shifts position on the sensor during exposure, this can create blur across multiple pixels. This pixel displacement is known as pixel blur, and it can distort edges or shift measurements.

Even a single-pixel shift can disrupt algorithms for applications focused on dimensional accuracy or flaw detection. Exposure time is the calibration point that determines the difference between passable and precise. Slower inspections with static objects may tolerate some blur, while high-speed assembly lines require strict timing.

We’re here to provide you with more details.

Reach out today!

Fast vs. Slow Shutter Speeds: When to Use Each in Machine Vision

Fast shutter speeds and short exposure times are key when inspecting moving parts because they help "freeze" motion and avoid distortion. This is particularly helpful for reading barcodes, verifying labels, or detecting features on rapidly moving assemblies.

Slower shutter speeds are better suited for low-light conditions or static targets; allowing more light to reach the sensor helps brighten underexposed images. However, a more prolonged exposure introduces more room for error when objects move. In these situations, lighting must be adjusted to avoid blur. Shutter time varies depending on the task, and understanding how that timing shifts work is key to keeping inspections clear and consistent. Applications focused on surface flaw detection, for instance, may prioritize detail even at slower speeds, while part positioning systems favor speed to keep up with line throughput.

The Impact of Lighting on Shutter Speed and Exposure Time

Lighting and exposure work in tandem. As the shutter speed increases, less light hits the sensor; to compensate, systems often increase illumination or widen the aperture. But opening the aperture too far reduces depth of field, making it harder to keep the entire object in focus. This is especially important when inspecting objects with curved surfaces or varying heights, where consistent sharpness is required.

This balance becomes especially important on high-speed lines as a fast shutter with limited lighting can produce underexposed or noisy images; slowing the shutter may help capture more light, but increases the risk of motion blur. Finding the right balance includes coordinating lighting, lens aperture, and exposure time.

Discover more about this product.

Click here to book your demo.

Optimizing Shutter Speed for High-Speed Industrial Applications

In high-speed environments (like packaging lines or surface inspections on conveyor belts), accurate imaging depends on whether the camera can freeze motion clearly. When parts move during the exposure window, even slightly, they can blur across multiple pixels, making it harder to detect features, measure dimensions, or identify defects.

Many vision systems have built-in exposure control and fast global shutter technology that allows cameras to capture high-speed motion without distortion. Then, when paired with precise lighting and synchronized timing, they reduce the need for manual calculations or trial-and-error adjustments. Whether the goal is to read fine details on a fast conveyor or to capture consistent images in ever-changing conditions, optimized shutter speed settings help deliver reliable results.

Best Practices for Configuring Shutter Speed in Machine Vision Cameras

There’s no one-size-fits-all exposure time; it has to be tuned to match the application. The first step is to identify the minimum feature size that needs to be detected and the maximum speed at which the object travels. From there, calculate the exposure time needed to prevent more than 1/10 of that feature from shifting during capture. For example, if a component moves at 1 meter per second and the smallest feature is 100 microns, exposure time should be no more than 10 milliseconds.

Changing the shutter speed also affects how much light the sensor receives and how much of the object stays in focus. Faster settings reduce light intake, which means the system needs either stronger illumination or a sensor with higher sensitivity. Pushing gain too far can introduce electronic noise; it’s better to adjust shutter speed, aperture, and lighting as a group. That way, the camera produces stable and clean images without having to compromise on image quality.

Tools like programmable region-of-interest (ROI) settings and built-in exposure control allow for faster configuration and more precise capture across variable scenes.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Shutter Speed and Exposure Time in Machine Vision

How Do Machine Vision Cameras Handle Low-Light Conditions?

For low-light environments, machine vision cameras extend the exposure time, allowing more light to reach the sensor. However, this increases the risk of motion blur. To counteract that, systems may use brighter LED lights or increase sensor gain. Some cameras also allow for programmable shutter profiles that adapt exposure time automatically.

Can Adjusting Shutter Speed Help With Barcode or Label Inspection?

Yes. High-speed lines require fast shutter speeds to capture labels clearly without smearing. A short exposure time prevents motion distortion during rapid barcode scanning or text verification. Faster shutters are especially helpful when paired with global shutter sensors, ensuring that each frame captures the entire label cleanly.

What Role Does Shutter Speed Play in 3D Machine Vision Applications?

In 3D systems, like those using stereo vision or structured light, accurate depth mapping relies on synchronized exposures. A mismatch in shutter timing can cause misalignment in point clouds or depth measurements. Using a fast, synchronized shutter time helps maintain consistent geometry across frames, especially when inspecting fast-moving parts or generating real-time 3D models.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics