Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

What is Blob Analysis in Machine Vision?

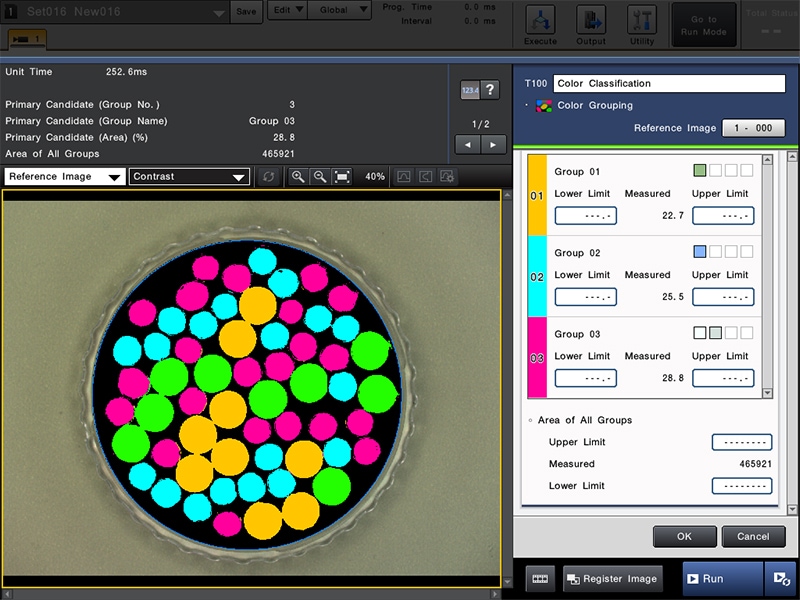

Blob analysis is a method in machine vision to detect and measure objects within an image where connected regions of similar pixel characteristics, such as color or intensity, are identified in order to isolate and assess features within an image. Once these areas are defined, the system refines the data to remove noise. Then these regions are measured and classified on predefined criteria. This process verifies that only relevant image data is examined, which helps reduce errors and improves the reliability of automated inspections.

How Blob Detection Works in Industrial Inspection

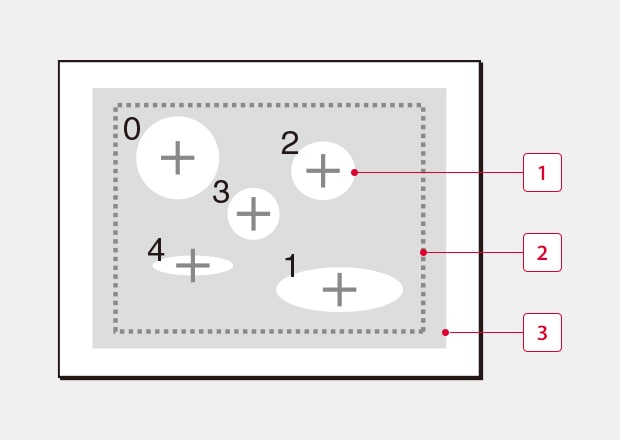

For most applications, blob detection starts by segmenting an image to isolate objects from their backgrounds. This is achieved through processing the image through different thresholds to help differentiate elements based on brightness, contrast, or color properties. Additional methods, such as Laplacian of Gaussian (LoG), Difference of Gaussians (DoG), and Determinant of Hessian (DoH), are applied to refine the image further to help verify that detected regions are relevant to the inspection criteria. Both the LoG and DoG methods are used to detect edges within an image, whereas the DoH helps determine the peaks and curves of the object in the image. When used together, these methods help reduce excess noise in images.

-

1Detected blob

-

2Processing region

-

3Workpiece to measure

Once the blobs are identified, additional refinement techniques are used to adjust and identify object boundaries and eliminate further inconsistencies. Morphological operations like dilation and erosion help correct distortions. At the same time, closing and opening filters remove artifacts that interfere with accurate analysis. Altogether, these adjustments make sure that the detected blobs accurately reflect physical objects rather than lighting inconsistencies or imaging errors.

Once the object is confirmed, the final step is feature extraction. This is where different attributes—like size, shape, and circularity—are measured. The characteristics of the object in the image will determine whether or not an object meets the required specification or if it needs to undergo further inspection. In the manufacturing environment, this step plays a key role in identifying defective components and making sure that only products that meet a manufacturer's quality standards move forward through the production process.

We’re here to provide you with more details.

Reach out today!

Key Applications of Blob Analysis in Automation

Robotics systems use blob detection to guide movement and object manipulation. Industrial robots on assembly lines depend on machine vision systems to tell the difference between different components, confirming that they have picked, placed, or assembled the correct parts accurately. Sorting applications rely on blob analysis to classify objects based on predefined attributes to direct products along different processing paths depending on their size, color, or shape.

Electronics manufacturing also benefits from blob analysis, particularly in circuit board manufacturing, as the exact placement of micro-components is necessary for functionality. Machine vision systems use blob analysis image processing to verify alignment, soldering integrity, and that each component is present. Automated optical inspections (AOI) systems scan boards for inconsistencies and identify missing or misplaced elements before final assembly.

In the lumber industry, blob detection is used to identify knots, cracks, and other structural imperfections in wood products. These systems help distinguish usable and defective sections, which helps cut down on material waste. In plywood, blob analysis is used to detect variations in the thickness and surface textures of panels before they are fused. Defects can be addressed before they proceed along the production line to maintain product quality.

Advantages of Blob Analysis for Quality Control

As blob analysis can inspect products at high speeds without making direct contact, it is a very effective tool in quality control. Manufacturers can identify defects and inconsistencies in real time before the products leave the production line and reach the market.

These machine vision systems can adapt to a range of different materials and surface textures while still providing consistent inspections. Measurements taken through blob analysis provide precise data that is used to assess an object's dimensions, spacing, and shape variations.

Best Machine Vision Systems for Blob Analysis

Choosing the right machine vision system depends on the complexity of the task. For applications requiring real-time, high-speed processing, vision systems with modular high-speed controllers are ideal as they support multiple camera configurations to inspect parts from different angles.

In other applications where blob detection is needed in a continuous operation environment, line scan vision systems are the optimal solution. They capture high-resolution images one line at a time, making them highly effective in sheet materials and fast-moving conveyor lines.

For robotics and automated material handling, vision-guided systems use blob analysis to locate and track objects in real time; these solutions incorporate 2D and 3D image processing into their process, allowing robots to recognize objects in tight and complex environments.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Blob Analysis in Machine Vision

What Is the Difference Between Blob Analysis and Edge Detection?

Blob detection and edge detection play different roles in image processing. Edge detection focuses on object boundaries by detecting abrupt changes, whereas blob analysis focuses on detecting entire regions that share similar characteristics like brightness or texture.

Can Blob Analysis Be Used for Barcode and OCR Applications?

While blob analysis cannot decode information in barcodes or optical character recognition (OCR), it can help isolate barcode regions and text, which helps improve readability for OCR software.

How Do Lighting Conditions Affect Blob Analysis Accuracy?

Lighting conditions are essential for blob analysis, as uneven illumination, reflections, and shadows can greatly distort object segmentation. However, advanced vision systems use multi-spectrum lighting and structured illumination to compensate for variation and provide stable lighting even in challenging environments.

How Does Blob Analysis Differ From Pattern Matching in Machine Vision?

Pattern matching relies on templates to recognize objects based on shape, structure, and orientation, while blob analysis identifies objects based on their connected pixel region.

Can Blob Analysis Be Used for Liquid Level Detection?

Blob detection is commonly used for liquid level measurements in bottling and chemical processing. The vision system can detect the contrast between the liquid and the container and determine the fill level.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics