Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

3 Key Processes Supported by 2D Vision-Guided Robotics

Manual pick-and-place operations have always been a challenge for production lines. Speed is expected, accuracy is assumed, and every adjustment to the line, whether a change in product, packaging, or tooling, should be fast enough to keep production moving without compromise.

That’s where 2D vision-guided robotics makes a measurable difference, as these systems combine repeatability and flexibility, streamlining inspection-driven processes such as pick correction, place alignment, and grip adjustment.

What Is 2D Robot Vision and How Does It Work?

A 2D vision system captures high-resolution images along the X and Y axes; these images are then processed using built-in tools such as AI detection, pattern recognition, or character recognition, depending on the task. While 2D vision lacks depth perception, it excels in inline applications where parts remain on a flat plane or where vertical variance is controlled.

KEYENCE systems build on this foundation with high-performance complementary metal oxide semiconductor (CMOS) sensors, lighting techniques like HDR and LumiTrax™, and software that doesn't require specialized experience. ZoomTrax technology, for example, dynamically adjusts the field of view and focus based on the size and height of the target; no lens swapping is required. Add AI tools trained on just a handful of images, and deployment becomes a short task rather than a long setup.

Because the robot’s movements rely on vision-based feedback, calibration has to be tight. KEYENCE 2D VGR systems handle that with one-click auto-calibration, which translates visual coordinates directly into robot instructions.

Get detailed information on our products by downloading our catalog.

View Catalog

Key Inspections Supported by Vision Guided Robotic Automation

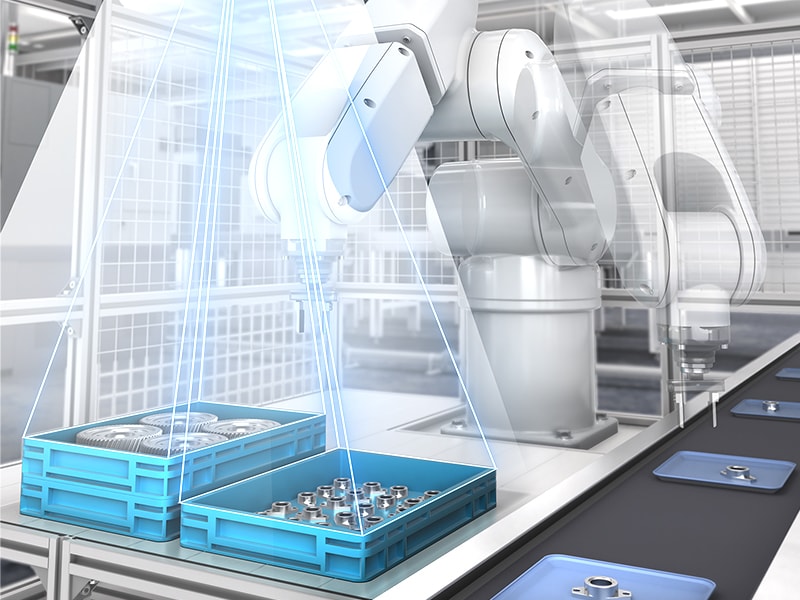

Positional Data for Robotic Picking

Even in tightly controlled environments, parts shift, and a misaligned target can disrupt downstream processes, particularly in high-speed picking tasks. Vision-guided robotics corrects this by identifying the precise location and orientation of each part in real time. Systems equipped with ShapeTrax™3A, for instance, can recognize features even when they are obscured by glare or noise, which is ideal for picking from reflective trays or textured backgrounds.

With smart illumination and distortion correction, robots can accurately isolate viable pick targets, even when parts overlap or are stacked edge-to-edge. This minimizes downtime caused by retries and supports stable picking across a broader range of part conditions.

Guidance for Robotic Placement

Placement precision isn’t just about coordinates; it’s about angle, scale, and tolerance. 2D vision-guided robotics systems make sure that when a part moves from one station to the next, it lands precisely where it should and in the correct orientation. These systems provide immediate feedback if something shifts out of spec and allow robots to correct for minor changes in placement targets, trays, or carrier positions.

Using HDR imaging and multi-spectrum lighting, KEYENCE vision systems maintain clarity across wide fields of view. That means the outer edges of a placement zone are just as reliable as the center, a detail that matters when positioning parts on large pallets or within tight tolerances.

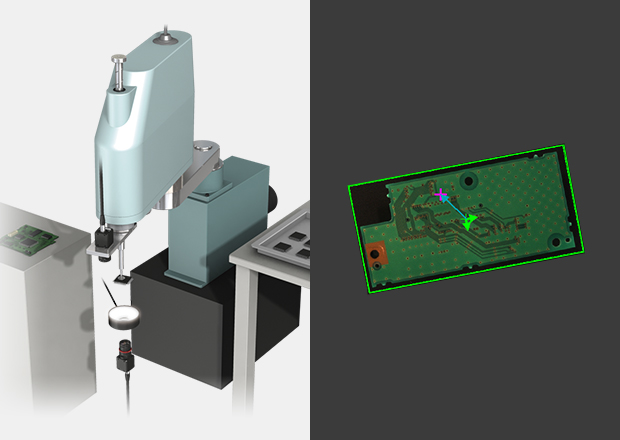

Grip correction during circuit board loading

Accurate position and orientation values are output.

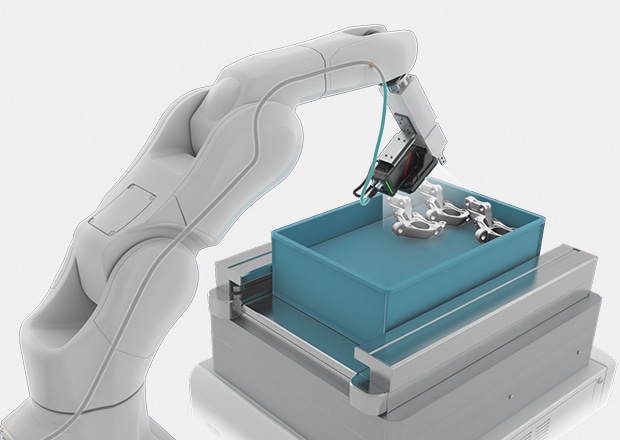

Grip Correction

When a robot’s end effector needs to adjust its angle, force, or engagement point based on part variability, vision plays an important role. 2D VGR systems identify subtle differences in part geometry, edge profiles, and orientation. That data feeds directly into grip strategies, helping prevent dropped components, over-applied pressure, or misalignment that might damage either the part or the gripper.

KEYENCE on-arm camera options support these tasks with IP67-rated housings, internal cabling, and auto-focus optics. The result: robots that can handle complex grips with repeatable consistency, even when tooling changes or environmental factors come into play.

We’re here to provide you with more details.

Reach out today!

Advantages of Using Vision-Guided Robotic Systems for Inspections

Vision-guided robots bring a different kind of efficiency to the floor. They don’t just follow pre-programmed paths; they adjust in real time, reducing reliance on fixtures or precise part placement. That flexibility matters most in facilities where line configurations change frequently, where multiple SKUs run on the same cell, or where manual intervention is costly and slow.

Beyond flexibility, these systems improve inspection quality. AI-assisted tools in the VS Series reduce false detections by combining supervised and unsupervised learning models. That’s especially important when small defects like chips, stains, or scratches could be mistaken for acceptable variation. Teaching the system what “good” actually looks like reduces the margin for error without increasing the rejection rate.

By shifting inspection and manipulation tasks away from human operators, manufacturers reduce exposure to repetitive motion injuries, high-speed lines, and sharp components. That benefit compounds over time, both in productivity and incident reduction.

Vision-guided robotics helps reduce costs, minimize scrap, limit rework, and protect downstream tools by identifying issues earlier, preventing damage, delays, and quality escapes.

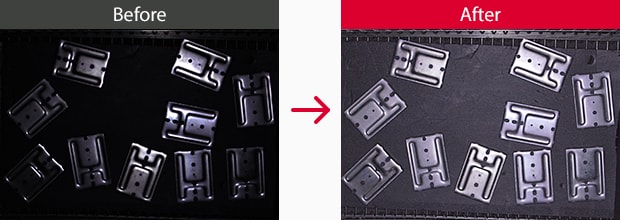

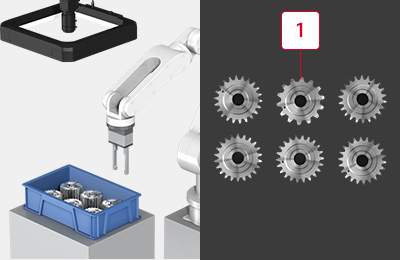

Difference Checking

Simultaneous sorting by part type, front/back, and orientation is performed.

-

1Different type

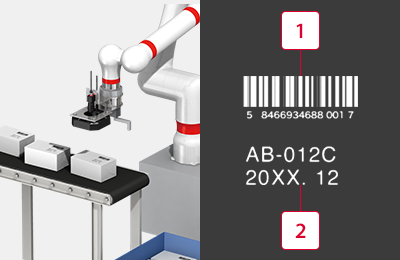

Identification Inspection (OCR, 1D/2D Codes)

Position detection and character reading are performed at the same time.

-

11D code reading

-

2Character recognition

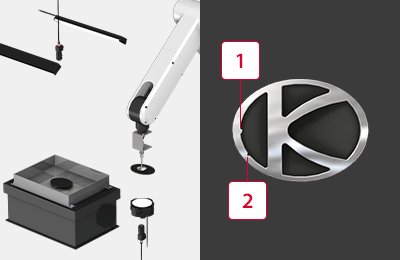

Appearance Inspection

After picking, products are inspected and rejected if defects are found.

-

1Burr

-

2Chip

Discover more about this product.

Click here to book your demo.

Integrating 2D Vision-Guided Robotics Into Your Production Line

Integration used to be the most time-intensive part of automation. KEYENCE systems simplify this process with intuitive programming environments, such as VS Creator, a software interface that supports both basic and complex inspection logic using drag-and-drop tools. There’s no need to write custom code or navigate robot-specific drivers manually.

Connection to major robot manufacturers is built in. From Mitsubishi and FANUC to Yaskawa and Universal Robots, robot-specific programs can be auto-generated and debugged directly through the vision system. Whether the camera is mounted overhead or on-arm, the setup is consistent, and setup replication tools make it easy to duplicate success across additional stations.

For facilities already running existing automation, the addition of 2D vision-guided systems can be non-disruptive. Power-over-Ethernet simplifies cabling. Internal memory handles backup and diagnostics. IP67 enclosures enable systems to be installed in areas where exposure to dust, oil, or washdown would normally be a barrier.

Curious about our pricing?

Click here to find out more.

Driving Manufacturing Excellence with KEYENCE 2D Vision Guided Robotics

The value of 2D vision-guided robotics isn’t theoretical. It’s real, measurable, and already in play across facilities that depend on speed, precision, and adaptability. With KEYENCE systems, pick, place, and grip operations don’t just get automated; they get smarter, faster, and more stable.

From lighting to software to installation, these systems are engineered for performance without complexity. That means less time spent troubleshooting and more time moving the product.

Ready to Revolutionize Your Production Line?

Discover how 2D vision-guided robotics can streamline your inspections, boost efficiency, and reduce costly errors, all with minimal setup and maximum ROI.

Contact a KEYENCE expert today to schedule a demo and see vision-guided robotics in action.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics