Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

3D Vision for Consumer Product Applications are Reshaping Manufacturing

The increasing demand for quality and safe consumer products also means more demand for improved productivity in factories. To get more units to the market, manufacturing and production lines need reliable vision systems to solve manufacturing lines and inspection issues that conventional machines and equipment can't solve.

3D vision systems provide quality inspection for consumer product manufacturing needs and can identify imperfections in intricate components with impressive precision in mass production. These vision systems are already revolutionizing manufacturing processes, hence the need for manufacturers to key into this revolution.

Importance of 3D Vision Applications in Product Manufacturing Quality Control Processes

Some of the problems facing manufacturers of consumer products stem from limitations in manual work and conventional vision inspection systems. Human inputs, errors, limitations in work speed, personnel selection challenges, and the hazardous nature of work can all be hindrances to quality control.

Conventional inspection and quality control equipment can’t provide accurate target detection in modern applications. For example, traditional robotic systems often have issues coordinating robot arms with obstacles in the work environment due to a lack of the required guiding system. Old systems also require large investments and setups.

Modern 3D vision solutions can guide industrial robots in assembly and inspection tasks. Their streamlined, yet robust design provides manufacturers with accurate detection in quality control efforts.

-

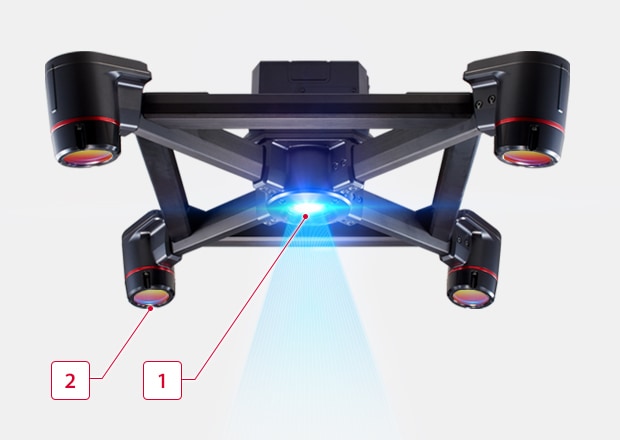

1Projector

-

24 cameras

-

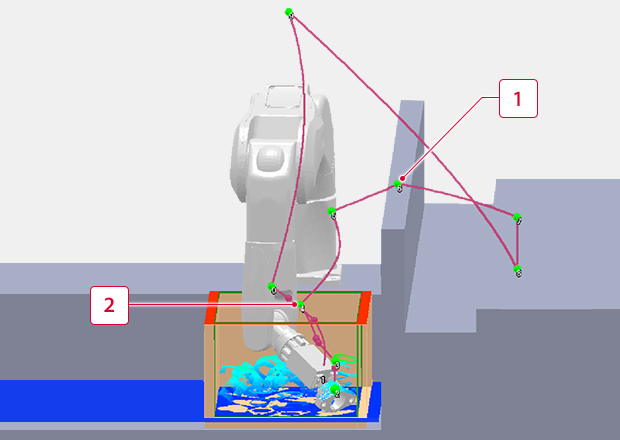

1Automatically calculates paths that avoid obstacles

-

2Automatically calculates paths where the arm doesn’t interfere with the container

Precise Defect Detection and Analysis

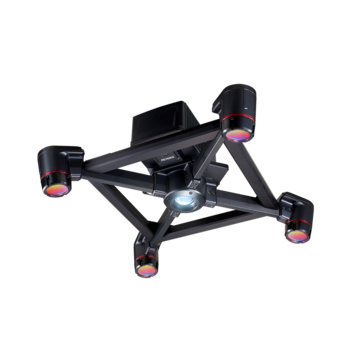

Modern 3D machine vision systems have high-resolution cameras, sensors, processors, and advanced scanning functions designed to complement robotic operations.

Modern 3D vision systems for consumer products have high-quality cameras and sensors to capture high-quality images from all angles, eliminating blind spots and creating stable 3D images. This technology helps account for differences in product color and shape. The 3D vision module can detect irregularities and deviations from preset criteria and feed the data back in real-time to the designated monitoring unit.

Processors in modern 3D vision for consumer product manufacturing can quickly extract object features, positions, dimensions, and other relevant details to distinguish between genuine articles and foreign materials.

Stable and continuous image capturing is another crucial part of accurate detection. Modern systems have features to optimize energy savings to ensure non-stop operation.

cardboard box depalletizing

Quality Consistency in Mass Production

In mass production sites, consistency in 3D vision for consumer product manufacturing translates to consistency in product quality. This is hard to achieve solely with conventional measurement and inspection efforts. Human vision could suffer from fatigue, or the human inspector could be distracted by their environment or personal issues. In small-scale manufacturing lines, any limitations in human effort may not be felt, but in large-scale, fast-moving production lines, it’s a concern.

Conventional vision guidance systems could also be hard to set up, limited in operation, and may not be compatible with existing robotic systems. Due to incorrect 3D vision path planning design, robot arms may often collide with objects or have issues picking targets from piled, stacked, or disorderly materials/locations.

Consumers are very keen about their products when it comes to consistency in size, taste, and attention to detail in packaging. They are quick to notice differences in product quality against what they are used to. Instead of manufacturers relying on conventional systems that are limited in operation, they can improve the consistency of goods by employing advanced 3D vision technology.

Reshaping Quality Assurance Practices

KEYENCE offers vision-guided robotics solutions that are reshaping quality assurance practices. For example, the 3D VGR Series is designed with unparalleled object detection capability, easy-to-use software, high-quality cameras, powerful processors, and more functions.

The vision system can be used for process and product quality inspection. It continues to deliver in assembly automation, de-palletizing, machine tending, and other industrial applications. It can also be used to inspect consumer products such as smartphones, gaming consoles, and smart home devices.

Advanced four-camera and one-projector imaging units work together simultaneously to capture 136 unique images subsequently sent to the processing unit. The newly introduced processor provides ultra-fast 3D calculations that generate a single 3D image from the captured images. This design not only ensures that the best image is selected but also helps inspectors to get optimal defect detection and inspection results.

Moreover, the user-friendly interface and easy-to-use software enable in-house technicians to easily manage and monitor the system. Features like one-click, 3D auto-calibration let operators calibrate the shutter speed to match the target’s environment and condition. This means there’s no need for manual, time-consuming calibrations. Also, professionals can make minimal manual system changes.

Curious about our pricing?

Click here to find out more.

Driving Efficiency and Accuracy in Product Manufacturing Through 3D Vision Solutions

3D vision solutions play a crucial role in driving accuracy and efficiency in industrial and manufacturing applications. By leveraging the capabilities of 3D vision for consumer products, manufacturers can reduce defects, streamline manufacturing processes, and improve productivity. Below are ways in which 3D is transforming product manufacturing inspection.

Robot Guidance

In many modern industrial applications, robots perform tasks like welding, pick-and-place, and material handling. In applications like these, operation accuracy and efficiency are important. The use of 3D visions helps coordinate robot arms and other machines, so they work together seamlessly.

Defect Detection

3D solutions use powerful cameras and intelligent sensors to detect defects early. This enables the removal of faulty products or components from reaching the final stages of production.

Accurate Measurement and Inspection

3D vision systems can help in measurement efforts by providing a 3D profile of a target object or material. This way, production managers can quickly detect production batches riddled with issues. This also helps with inspection needs before, in the middle of, and post-production.

KEYENCE’s 3D vision-guided robotics technology can help with efficient and accurate inspection and other industrial applications.

Ready to invest in 3D vision systems? Check out KEYENCE 3D vision for consumer products today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics