Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

Comparing Human Vision vs Machine Vision Benefits in Industrial Inspection

Product inspectors, inspection technicians, and professionals in similar roles frequently consider the differences between human vision vs machine vision. While human vision has its strengths, machine vision technologies have transformed the field in terms of accuracy, speed, and consistency. As a result, many progressive companies are now adopting this advanced technology to enhance their inspection processes.

This blog explores the differences between human vision and machine vision to highlight the benefits of integrating machine vision systems into your product line or any facility where inspection is essential.

Exploring the Differences Between Human Vision vs Automated Vision Systems

Human and automated visual inspection have both been crucial tools in manufacturing and will remain integral in areas such as quality control and packaging for years to come.

While many industries are already exploiting machine vision to complement human inspection, some have yet to adopt it and are, therefore, missing out on the benefits that machine vision systems can offer.

Let’s go over the differences between human vision vs machine vision systems:

Accuracy and Consistency

Human vision and machine vision play a role in industrial inspection but differ in their capabilities. Human inspectors can interpret data based on context, as well as incorporate sights, sounds, and problem-solving skills when carrying out inspections.

Their accuracy and consistency, however, can take a hit due to exhaustion from long hours. Manufacturers can’t afford to risk product recalls, regulatory penalties, or reputation damage due to the wrong batch of products getting to market because of an inspection error.

This is where machine vision comes in. Perhaps the biggest difference between human vision and machine vision is the capability of the latter to be precise and produce consistent results.

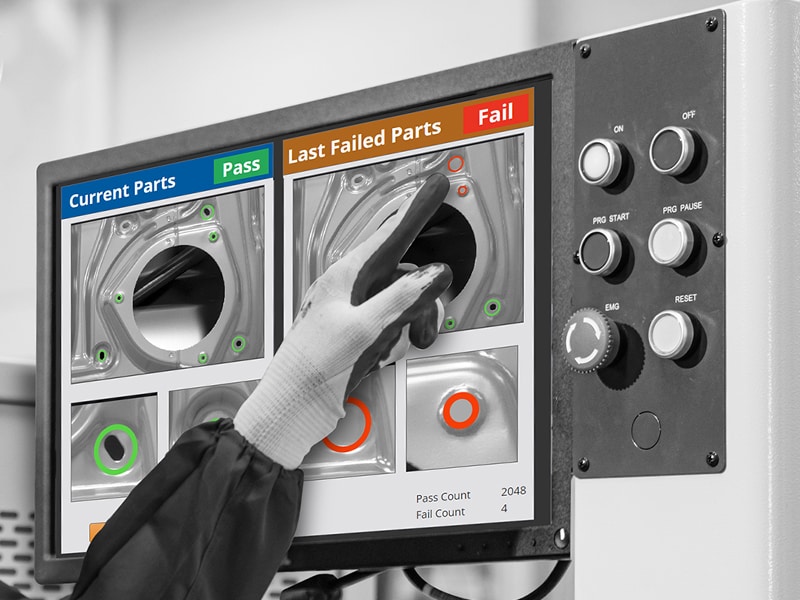

Machine vision systems comprise smart cameras, high-speed controllers, and artificial intelligence units. They are not susceptible to distractions or fatigue and can deliver results equal to and often above human performance.

When you invest in the right vision systems, you’ll get a customized vision system that’ll transform your business processes and complement your human inspection efforts.

Adaptability and Flexibility

Human visual inspection may struggle to detect subtle variations and defects in product packaging and products. Training employees for these nuances could take time that the business doesn’t have or might be impossible due to individual strengths and weaknesses. For instance, some individuals may perceive colors differently from their actual appearance.

On the other hand, machine vision can be programmed to detect and sort through numerous product types based on features such as size, color, shape, and quality. Vision systems can also be programmed to detect defects and anomalies such as scratches, foreign material, and short shot/flash, making the system flexible and adaptable.

While human vision will perform well sorting through a few hundred or thousands of product units, it may struggle with large-scale production due to fatigue and similar factors.

The ability to program machine vision technologies to detect, classify, and identify different types of items makes them adaptable to different production inspection needs.

Speed and Efficiency

Some manufacturing line processes are too fast for an operator to inspect. The human eye can process about 10 to 12 images per second, while a vision system can speed through thousands of parts per minute. An example in the food industry would be packing 1,000+ snacks per minute. Inspecting for incorrect sealing or discolored labeling in a situation like this is impossible for a human inspector, but with the right machine vision system, it’s a simple task.

Machine vision outperforms human vision in this aspect. Granted, limitations like insufficient or excessive lighting and calibration issues can hinder the efficiency of machine vision. Nevertheless, these factors do not diminish the capabilities of the technologies, particularly when opting for industry leaders in vision systems like the KEYENCE VS Series or CV-X Series.

Reliability and Consistency

Human vision is susceptible to bias, potentially resulting in inaccurate assessments and suboptimal decision-making. When properly installed and maintained, machine vision systems deliver precise and consistent results, surpassing the capabilities of human inspection efforts.

KEYENCE takes pride in AI vision systems built with advanced algorithms that follow both AI and rule-base programming to identify, classify, and detect shape, color disparities, target presence, and other features in industrial inspection with machine-like precision.

Curious about our pricing?

Click here to find out more.

Integrating Vision Systems for Optimal Results in Industrial Settings

Thanks to advancements in cameras, artificial intelligence, and hardware systems, vision systems are increasingly integrated into industrial processes. However, a vision system’s purpose is not to eliminate human input but to complement human efforts, ensuring the safety and quality of consumer products. The main goal is to deploy vision systems that outperform humans in terms of accuracy, speed, and efficiency.

With that said on comparing human visual inspection versus machine vision, here are some advantages of investing in machine vision for your inspection needs:

- Machine vision can achieve high-speed, accurate inspection 100% of the time. This is impossible with manual, human inspection.

- Cost is more accessible than ever before and financially makes sense from an investment standpoint.

- Image processing and data interpretation far outperform those achieved by human eyes, manual processes, and conventional equipment.

Ready to explore how vision systems can be integrated into your food, automotive, or other manufacturing processes?

Contact KEYENCE today

for more information. Our engineers can help you determine the ideal camera, software, and hardware solutions for your facility.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics