Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

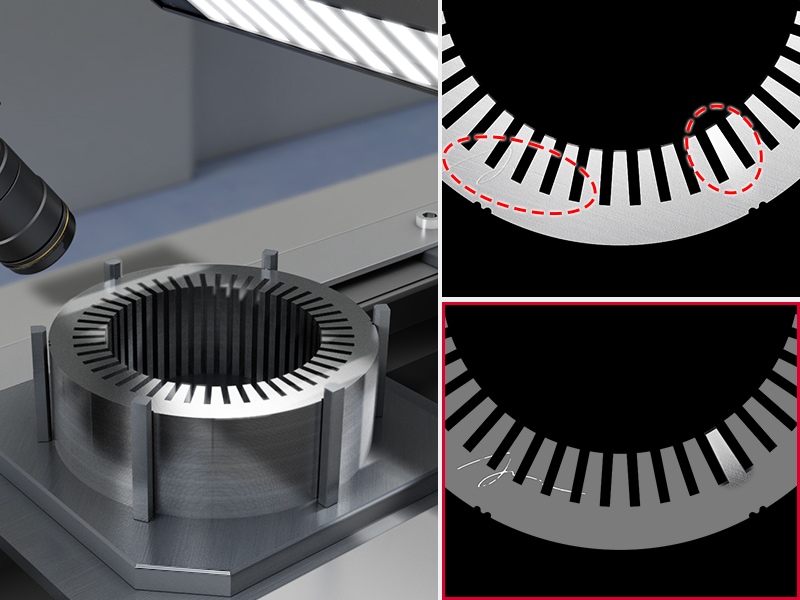

Detecting Hairline Scratches and Stains on Glossy Surfaces With LumiTrax™

Glossy surfaces are quite common in manufacturing. While they are sometimes used for their material properties, like resistance to corrosion, contamination, and wear, they also bring about one major challenge for inspections: glare. These polished metals, high-gloss plastics, and protective coatings can easily fool some traditional vision systems into thinking their surface is flawless, but behind the glare, many imperfections can hide.

The Persistent Challenge of Inspecting Glossy Surfaces

A small scratch can easily blend into a shine in the background, and a light stain can disappear under direct lighting. Pair this with other inconsistencies in the machine vision surface inspection process, like operator error and incorrect inspection setup, and you have a recipe for higher scrap rates, parts/products with defects reaching the customer, and a general lowering of manufacturing standards. This can be especially prevalent when you are dealing with high production speeds.

There are many industries where safety is involved, such as automotive, medical, and electronics, and inconsistent inspections/part quality can have extreme consequences. When a missed defect can compromise a patient’s health or a passenger's safety, manufacturers need a vision system that can see through the glare and evaluate what is truly on the surface.

We’re here to provide you with more details.

Reach out today!

Introducing KEYENCE Breakthrough LumiTrax™ Technology

To solve this problem, KEYENCE engineers developed LumiTrax™, a proprietary technology that brings machine vision solutions to a new level. Instead of relying on one lighting angle or one image capture, LumiTrax™ takes a multi-illumination approach. A striped pattern of light is projected onto the target, and multiple images are captured in quick succession. Advanced algorithms then compare these frames to extract surface irregularities while removing background patterns, glare, and reflections.

This results in:

- True Surface Defect Detection: Scratches, stains, pits, or dents are highlighted.

- Stable, Repeatable Inspections: Results don’t vary based on operator setup or environmental changes.

- Simplified Operation: No need for complex lighting rigs or trial-and-error configurations.

Enhanced Detection of Hairline Scratches and Stains

For a lot of industries, hairline scratches and stains are the most common defects that restrict a percentage (that is always too high) of their products from being released. They may not always affect functionality, but they directly impact quality perception and compliance. For example:

- Hairline Scratches: On polished automotive trim, consumer electronics housings, or surgical tools, a scratch measured in microns can trigger a rejection from the machine vision system. LumiTrax™ enhances the scratch by separating it from surrounding glare, making it stand out with precision.

- Stain: Light discoloration or contamination can compromise the appearance, sealing, or sterility of a part or product. LumiTrax™ can isolate the stain from reflective backgrounds and/or surfaces, enabling automatic detection by the machine vision system.

- Foreign Particles: Dust, fibers, and micro-debris are easily mistaken for harmless reflections under conventional lighting. LumiTrax™ filters them out as true surface defects.

Discover more about this product.

Click here to book your demo.

KEYENCE Vision Systems Leveraging LumiTrax™ for Your Application

LumiTrax™ itself isn't a standalone product; it integrates into a variety of KEYENCE vision systems to enhance machine vision surface inspection capabilities. It gives the manufacturers and operators a number of different avenues when deploying the technology, and can allow them to tailor the tech to their specific environment.

- VS Series: The VS Series complements LumiTrax™ applications with AI-based defect detection. Together, these systems cover both cosmetic and functional inspections for the best results possible.

- CV-X and XG-X Controllers: The CV-X focuses on usability and rapid deployment, while the XG-X offers customizable, flowchart-style programming for advanced users.

- VJ Series: Ideal for integration into existing PC-based setups, the VJ Series combines LumiTrax™ with high-resolution GigE cameras and dynamic lighting. It’s compatible with popular software environments such as HALCON and OpenCV, making it flexible for custom applications.

Curious about our pricing?

Click here to find out more.

Real-World Impact Across Industries

The power of LumiTrax™ can be seen across a multitude of industries where glossy or reflective surfaces are unavoidable:

- Automotive: Detects scratches on trim, dents in panels, and contamination on glass, ensuring both appearance and safety standards.

- Electronics: Reveals micro-scratches and stains on housings, screens, and assemblies where flawless finishes are critical.

- Medical Devices: Identifies cosmetic and functional defects on tools, implants, and packaging to meet FDA and ISO compliance.

- Food & Packaging: Uncovers hidden contamination and sealing issues on glossy films, wrappers, and blister packs.

Experience the KEYENCE Advantage

Every model and system that is part of our lineup is backed up by a team of experts who provide technical support, from training new users all the way to integrating the systems into existing production lines. With KEYENCE LumiTrax™ technology and AI defect detection in particular, any and all defects on glossy surfaces can be detected.

Ready to Optimize Your Inspection Process?

Contact KEYENCE today to explore how we can transform your inspection process, or you can check out some of our other resources here.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Unique Challenges Do Glossy Surfaces Present for Visual Inspection?

Glossy surfaces typically produce reflections and a glare that can hide a lot of small details. With conventional lighting setups, stains, scratches, and other imperfections become much harder to detect on glossy surfaces.

What Types of Defects Can KEYENCE Machine Vision Inspection Systems Precisely Detect on Glossy Surfaces?

Hairline scratches, faint stains, pits, dents, foreign particles, and other micro-irregularities are all types of defects that KEYENCE machine vision inspection systems can detect.

How Do KEYENCE Vision Systems Ensure Stable and Reliable Machine Vision Defect Detection?

KEYENCE vision systems combine LumiTrax™ patterned lighting with high-resolution cameras to get rid of any background glare and produce the correct contrast. This creates the perfect conditions for machine vision defect detection.

In Which Industries Are KEYENCE Vision Systems Commonly Applied for Quality Control and Inspection?

Automotive, electronics, medical devices, food and packaging, plastics, and any industry where surface quality directly impacts safety, compliance, or brand perception.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics