Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

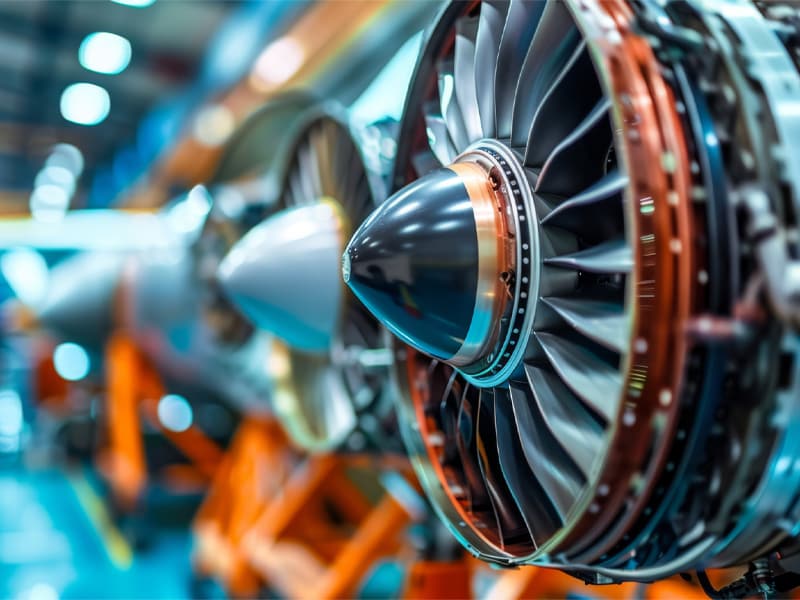

Exploring the Benefits of Machine Vision in Aerospace Manufacturing

Due to the complexities of production requirements in aerospace manufacturing, line operators and managers need reliable vision systems for precision-based inspections. Machine vision systems in the aerospace industry have proven to be reliable for identifying defects, processing captured data, and helping analysts make data-driven decisions. Recent advances in high-speed vision technology provide even more benefits to aerospace manufacturing lines.

Explore the benefits of recent machine vision systems and how KEYENCE vision solutions can help transform any aerospace manufacturing inspection needs.

How Machine Vision and AI Are Addressing Aerospace Manufacturing Challenges

Completing complex manufacturing processes with precision and meeting quality standards are some concerns aerospace component manufacturers should address.

Quality standards set by regulators require every component and system design to be reliable. This is a reasonable requirement for the safety of those using aerospace innovations and products.

Machine vision in aerospace helps manufacturers meet the ever-increasing quality control standards. Vision systems capture details on critical parts and components to reveal possible defects and inconsistencies in production elements. They also guide robots used in picking and placing, packaging, and product sorting applications.

By combining a camera, image processing unit, and hardware to analyze images, machine vision solutions help line operators and managers to complete intricate manufacturing processes with precision and accuracy. This way, manufacturing lines can build dependable systems and remain compliant with regulatory standards. Machine vision systems used in the aerospace industry can also capture defective images and save them with timestamps for traceability.

The introduction of AI defect detection to machine vision in aerospace has improved detection even further. Vision systems with AI technology can learn from a taught dataset to distinguish between good and bad samples, helping aerospace industry manufacturers solve challenges related to quality and safety.

How 3D In-Line Inspection Improves Solder Checks and Assembly Accuracy

Soldering is the fusing of electronic components on a printed circuit board (PCB). It's important to verify the quality and integrity of solder joints on the microscopic copper pathways of a PCB to ensure reliable connections. Due to how minute components on a PCB are, inspection through human or manual vision is not ideal, making machine vision systems a requirement.

Aerospace vision inspection for solder accuracy must be carried out in-line, not after final assembly. Carrying out necessary checks at designated manufacturing points helps operators and managers detect defects in real time, identifying issues that could lead to individual component malfunctions or entire system failure.

Vision technologies offer 3D in-line inspections for three-dimensional imaging of targets. 3D data helps with solder defects such as voids, cold joints, and excess solder. 3D inspections can help human operators make informed intervention decisions and process changes as needed.

We also have vision system options for 3D-guided robotics applications. Cobots and other types of robots are increasingly used in different manufacturing industries, including aerospace, to complete pick-and-place tasks and others. 3D vision systems can be used for controlled guided robotics.

Role of OCR for Improved Traceability and Tracking in Aerospace Manufacturing

An aerospace vision inspection system should be able to provide optical character recognition (OCR), 1D/2D code reading, and grading. These three provisions help in tracking and tracing products, parts, and components in aerospace manufacturing.

OCR technology helps capture, process, and recognize serial numbers, part numbers, and other identification codes for further processing and analysis by the vision system. Manufacturers can use this when tracing components throughout the supply chain.

1D/2D code reading is also important for traceability and tracking. Vision systems can read, verify, and output encoded data in 1D or 2D codes. Encoded data may contain part numbers, lot numbers, or other critical information. Although the application of 1D barcodes is now limited in aerospace manufacturing, vision systems should still be able to support them.

Also, machine vision in aerospace inspection can help assess the quality of text, unique identifiers, and barcodes. Clear coding goes a long way in storage, product documentation, and inventory management.

Application of High-Resolution Cameras for Detecting Small Defects on Critical Parts

High-resolution cameras are fundamental to precision-based aerospace defect detection. They are especially required to capture microscopic defects and complex geometries.

With so many small electronic components, it’s not uncommon in printed circuit board manufacturing to encounter minute flaws that could compromise the performance of individual components or the entire system. High-resolution cameras are required to capture cracks, dents, discolorations, debris, and tiny imperfections. High-resolution imaging is also a requirement for aerospace parts with intricate shapes and surfaces.

Curious about our pricing?

Click here to find out more.

Transform Your Aerospace Manufacturing With KEYENCE Vision Systems

As a leader in automation and machine vision, we offer a range of vision systems designed with various configurations and capabilities. These vision systems have features that facilitate in-line 3D vision inspection and measurements, precise optical character recognition, high-resolution imaging, AI functionalities, and much more.

KEYENCE vision systems with AI use defect detection tools that learn to identify good samples and flag deviations as defects. The AI also timestamps defect locations for traceability. This is crucial in aerospace manufacturing, where traceability is essential for regulatory compliance and identifying potential maintenance or safety issues.

Models with advanced projectors provide various lighting levels for inspecting defects on materials like aluminum, metal, and carbon fiber, ensuring accurate detection in diverse lighting conditions. This ensures all components meet strict quality standards before integration into larger assemblies.

KEYENCE vision systems use high-resolution cameras and powerful processing units to analyze even the tiniest imperfection on critical parts like magnets. Some other benefits provided by vision systems are immediate feedback and robotic inspections. With the help of AI defect detection, our solutions help managers and operators see how events unfold, which helps in critical decision-making.

For more information on how vision systems can help improve aerospace manufacturing measurement and inspection, contact us today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics