Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

OCR vs. OCV: A Clear Guide to Character Inspection With KEYENCE Vision Systems

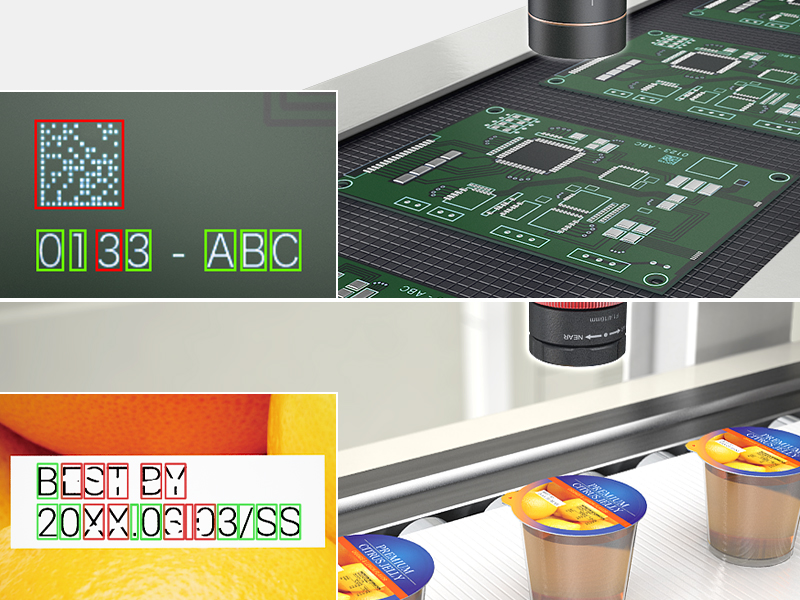

Every mark matters. Lot numbers, expiration dates, and serial numbers all have a role to play in making sure traceability, quality control, and compliance standards are upheld. There are several ways to inspect characters, but not all methods are created equal.

Optical Character Recognition (OCR) reads characters, and Optical Character Verification (OCV) makes sure they are legible. We’ll go through how OCR and OCV are different, and how KEYENCE vision systems bring both performance and usability to the character inspection game.

The Critical Role of Character Inspection in Modern Manufacturing

Character inspection goes beyond simply 'reading' numbers or text. The information printed on parts, products, or even food items is often directly linked to crucial details such as serial numbers, expiration dates, or other vital product information. If this text or these numbers are illegible, it can result in costly recalls, food waste, and compliance violations.

The stakes are even higher in industries like pharmaceuticals, where product quality is directly tied to an individual’s health. Missing, incorrect, or illegible information on medication can lead to severe consequences.

We’re here to provide you with more details.

Reach out today!

Understanding the Nuances: OCR vs. OCV

Machine vision OCR (Optical Character Recognition) is designed to identify and read printed or marked characters. It “decodes” letters and numbers from an image and converts them into usable data.

Machine vision OCV (Optical Character Verification), on the other hand, checks whether a printed or marked character matches an expected pattern. Instead of “reading,” OCV is about verifying accuracy, completeness, and legibility.

Key Distinction: OCR answers “What does this say?” while OCV answers “Is this correct?”

Overcoming Manual Inspection Pain Points With Automated Character Reading

Manual inspection is known for being slow, inconsistent, and extremely prone to human error. These issues are multiplied when the characters are either faintly printed or on curved or shiny surfaces that make them harder to read. Also, it is important to remember that human performance declines over time; inspection quality at the end of a shift is rarely as sharp or consistent as it is at the beginning.

Automated character reading has many advantages over manual inspection. Automated OCR vs OCV powered by vision systems eliminates:

- Operator fatigue and subjectivity

- Misreads due to environmental factors (dust, glare, lighting shifts)

- Bottlenecks caused by random sampling instead of 100% inline inspection

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

How KEYENCE Vision Systems Provide Unparalleled Character Inspection

KEYENCE vision systems simplify character inspection by bringing together a number of different technologies like high-resolution imaging, AI algorithms, and ease-of-use. Their vision systems possess the following features that make them extremely effective at character inspection:

- OCR that uses AI to adapt to variations in print quality, orientation, or surface texture

- AI-based character verification that learns acceptable variations while flagging genuine defects

- Flexible libraries that allow fast switching between multiple product types

- Integration with robotic and automation systems for full in-line inspection

Key Applications of KEYENCE OCR and OCV

KEYENCE machine vision OCR and OCV solutions are trusted across industries where precision and compliance aren’t optional. Key applications include:

- Pharmaceutical & Medical Devices: Ensuring full FDA and EU compliance by verifying lot numbers and expiration dates.

- Automotive & Aerospace: Confirming etched serial numbers are accurate and legible to maintain strict traceability standards.

- Food & Beverage: Inspecting date codes and package markings to prevent labeling errors and costly recalls.

- Electronics & Semiconductors: Accurately reading micro-printed IDs on PCBs and components, even at the smallest scales.

Discover more about this product.

Click here to book your demo.

Discover the Right KEYENCE Solution for Your Needs

Whether your goal is to reliably read characters across challenging print conditions (OCR) or to confirm that every mark meets exact specifications (OCV), KEYENCE has you covered. Each system combines high-resolution imaging, AI-driven tools, and world-class optics to deliver stable, accurate inspections in any environment.

- VS Series - Vision System with Built-in AI: Smart cameras with one-click optical zoom and easy setup, ideal for fast deployment of OCR/OCV and other inspections.

- CV-X Series - Intuitive Vision System: High-speed cameras with integrated lighting for stable defect detection, assembly verification, and code reading across industries.

- XG-X Series - Customizable Vision System: A flexible platform supporting 2D, line scan, and 3D cameras with advanced programming for complex, multi-camera inspections.

Ready to Implement Advanced Character Inspection?

Adding a KEYENCE machine vision solution to your arsenal is a huge step towards ensuring that the compliance, cost-effectiveness, and reduction in error is locked in for the foreseeable future. By utilizing OCR and machine vision OCV together, you will have both verification and recognition covered, and peace of mind that you have the most effective system in place to keep your operations as efficient as possible.

Explore KEYENCE vision systems today to see how machine vision OCR and OCV can elevate your manufacturing processes. Contact us today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Types of Products Are Available for Character Inspection From KEYENCE?

KEYENCE has a number of vision controllers, smart cameras, and AI-driven software that use algorithms to read and verify inline characters in a multitude of industries.

What Industries Commonly Rely on KEYENCE Machine Vision Systems for Character Inspection and Other Tasks?

KEYENCE machine vision inspection systems empower many different industries like pharmaceuticals, food and beverage, automotive, aerospace, electronics, and packaging. These are industries where traceability and compliance are crucial.

What Is the Primary Difference Between OCR and OCV?

OCR reads and converts characters into digital data, while OCV verifies whether printed characters match expected patterns and quality standards.

How Does KEYENCE AI Technology Enhance Character Inspection?

KEYENCE AI learns acceptable variations in print quality, compensates for environmental noise, and provides stable, high-accuracy results that reduce false rejects and missed defects.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics