Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

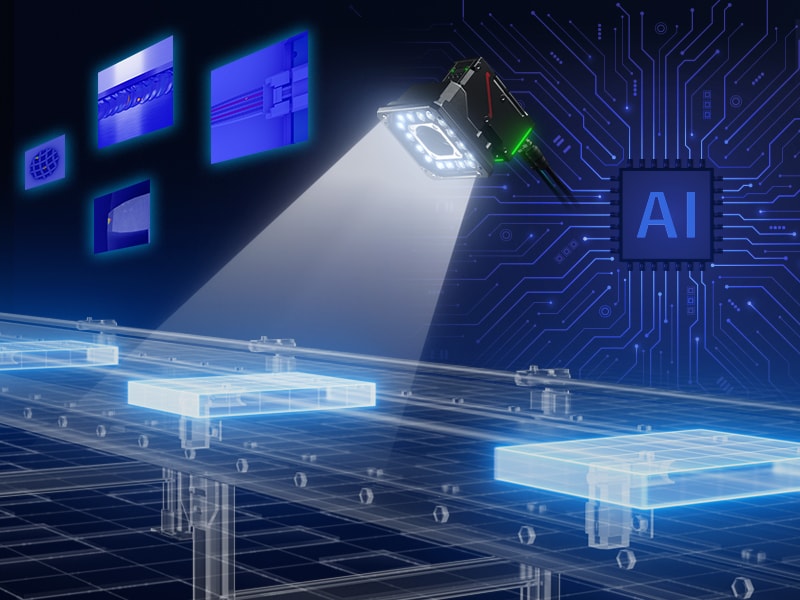

Uncomplicate Your Vision System with KEYENCE AI-Driven Features

Machine vision systems are increasingly being adopted in manufacturing, but they often come with a steep learning curve. This means they can take significant time to get up and running effectively, with all users fully trained. Even once set up, these systems require ongoing, time-consuming adjustments and specialized machine vision programming to maintain accuracy.

KEYENCE has developed a line of AI machine vision systems that solve these challenges. These systems combine AI-driven features, advanced vision technology like the VS Series, and an intuitive design to deliver fast, reliable inspections without the need for specialized technicians.

The Complexity of Traditional Vision System Setup

Traditional vision systems have long been held back by technical barriers. Choosing the right camera, lenses, and software often feels like navigating a maze. These systems demand expert-level knowledge for selection, installation, and operation.

Complexity leads to higher costs, starting with the need for expert consultations, extended training for employees, and increased expenses down the line if adjustments are needed to keep pace with production.

We’re here to provide you with more details.

Reach out today!

KEYENCE Vision Systems: Designed for Simplicity and Performance

KEYENCE revolutionizes AI machine vision system design by combining simplicity with advanced capabilities. The entire lineup includes all-in-one smart cameras, modular high-speed controllers, and advanced options for 2D, line scan, and 3D applications.

The VS Series stands out as a true breakthrough: a vision system with built-in AI that’s ready to use at any experience level. It delivers fast, accurate inspections across diverse applications while removing the traditional roadblocks that typically slow down deployment.

AI-Driven Features That Simplify Setup for Any User

One-Click Optimal Image Creation with ZoomTrax and AI-Image Reproduction

The VS Series is the world’s first smart camera to integrate ZoomTrax, which brings in an optical zoom function. This allows the user to create the optimal image in any conditions, with just one click of a button. When paired with AI image reproduction, it can copy image settings and standards across all images to simplify setup and ensure consistency.

Advanced AI Technologies for Enhanced Operational Efficiency

Whether running machine vision AI-powered inspections or leveraging rule-based vision tools, the VS Series adapts to the application. This combination provides speed, flexibility, and accuracy, giving manufacturers both simplicity and high-performance results.

Streamlined Inspection Programming

The intuitive machine vision software makes inspection setup straightforward even for first-time users. Preconfigured AI templates and an easy-to-use interface cut down machine vision programming time, enabling teams to move from concept to production much faster.

Get detailed information on our products by downloading our catalog.

View Catalog

Broader Benefits of KEYENCE Simplified Vision Systems

KEYENCE vision system solutions provide many benefits to operators in a multitude of industries. Here are the most common benefits seen across all use cases:

Improved Efficiency and Quality

KEYENCE machine vision AI-powered imaging tools ensure that every inspection begins with optimal image quality, minimizing false rejects and missed defects. By automating adjustments that once required trial-and-error setup, the system shortens changeover times and keeps production lines moving without interruption.

Enhanced Robotic Integration

The VS Series integrates seamlessly with robotic systems, enabling smooth handoffs between inspection, part handling, and assembly processes. This eliminates the common bottlenecks that arise when vision systems fail to align with automation hardware.

Cost Reduction and Safety

Simplified setup and intuitive software reduce the need for specialized training, lowering labor costs and ensuring operators can quickly adapt the system to new tasks. By catching defects earlier and preventing downstream errors, KEYENCE vision systems also help cut scrap, rework, and warranty costs.

Resources and Next Steps

Simplifying and streamlining your machine vision process doesn’t mean sacrificing performance. KEYENCE AI-powered vision systems deliver the power and precision you need, with an intuitive interface that makes them easy to use. Whether in manufacturing or other industries, the VS Series and the KEYENCE full lineup of machine vision solutions are built to tackle real-world challenges with unmatched efficiency.

Ready to uncomplicate your vision system? Learn more about KEYENCE machine vision systems directly from us. Contact us today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Makes KEYENCE Vision Systems Easy to Set Up for Any User?

KEYENCE systems combine machine vision, AI-driven tools, optical zoom, and intuitive software. This eliminates the need for most technical knowledge or experience when operating the system, meaning an operator of any skill or experience level can use the system.

How Does KEYENCE AI Technology Simplify Vision System Setup?

KEYENCE AI technology eliminates the need for manual fine-tuning by automatically optimizing inspection settings and image quality. This streamlined setup ensures fast, hassle-free integration, so your vision system is ready to perform at peak efficiency.

What Is ZoomTrax, and How Does It Contribute to Ease of Use?

ZoomTrax is the world’s first smart camera that has an optical zoom function included. You can create an optical inspection image with one click.

Why Is the Ai-Image Reproduction Feature Considered a “Star Feature” for Simplifying Setup?

It makes sure that the best image quality is produced by reproducing the image across multiple setups. It also keeps the image conditions consistent, which simplifies setup significantly.

How Many Images Are Typically Needed for the AI to Learn With KEYENCE VS Series?

Generally, it only takes AI a small set of images to start learning. In the case of the VS Series, it takes a few dozen images to learn.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics