Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

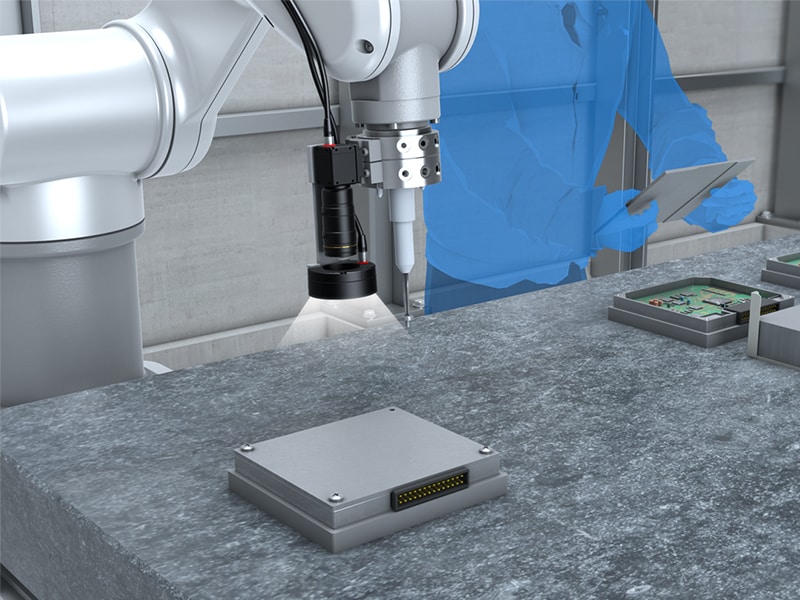

Using Collaborative Robots with Machine Vision

Key Takeaways

- Integrating cobots with machine vision enables precise, flexible automation for assembly, inspection, and handling.

- KEYENCE VS smart cameras offer easy integration, high-speed image processing, and robust defect detection.

- Vision-guided cobots enable part recognition, barcode reading, precise pick-and-place, and automated quality control.

- Deploying cobots and vision improves throughput, reduces errors, and scales from small batches to high-volume production.

The manufacturing landscape is rapidly evolving with the integration of collaborative robots that work safely alongside human operators. These robots, often called cobots, are revolutionizing automation by combining flexibility, precision, and ease of use. When paired with advanced vision technology, such as the KEYENCE VS smart camera, the potential of cobots with machine vision expands dramatically, enabling smarter, more efficient production processes.

The VS Series is an AI-powered vision system that optimizes industry processes through accurate visual analysis, allowing for rapid deployment for both inspection and guidance applications.

The Rise of Collaborative Robots in Industry

Collaborative robots are designed to assist human workers without the need for extensive safety barriers. Their adaptability makes them ideal for a wide range of tasks, from assembly and packaging to inspection and material handling. Unlike traditional industrial robots, cobots are easier to program and redeploy, making them a cost-effective solution for manufacturers looking to increase productivity.

One of the key drivers behind the success of collaborative robot applications is their ability to integrate with vision systems. This integration allows cobots to “see” and interpret their environment, enabling more complex and precise operations.

We’re here to provide you with more details.

Reach out today!

Enhancing Capabilities with Machine Vision for Collaborative Robots

Machine vision for collaborative robots is a game-changer in automation. Vision systems provide cobots with the ability to identify parts, verify quality, and guide their movements with high accuracy. The KEYENCE VS smart camera is a prime example of a vision system that offers high-speed image processing, advanced defect detection, and easy integration with robotic platforms.

By using the KEYENCE VS smart camera, manufacturers can implement cobots with machine vision to perform tasks such as:

- Part recognition and sorting

- Quality inspection and defect detection

- Precise pick-and-place operations

- Barcode reading and traceability

These capabilities reduce errors, improve throughput, and ensure consistent product quality.

Popular Collaborative Robot Applications with Vision Systems

The versatility of collaborative robot applications is greatly enhanced by vision technology. Some common use cases include:

- Assembly Assistance: Cobots equipped with vision systems can identify components and assemble them with precision, even when parts vary slightly in orientation or size.

- Quality Control: Vision-guided cobots inspect products for defects such as scratches, misalignments, or missing components, ensuring only high-quality items proceed down the line.

- Packaging and Palletizing: With real-time visual feedback, cobots can adapt to different package sizes and shapes, optimizing packing efficiency.

These applications demonstrate how cobots and vision systems work together to create flexible, intelligent automation solutions.

Discover more about this product.

Click here to book your demo.

Why Choose Cobots and Vision Systems Like the KEYENCE VS Smart Camera?

The combination of collaborative robots and advanced vision systems like the KEYENCE VS smart camera offers several advantages:

- Ease of Integration: The VS smart camera’s compact design and user-friendly interface simplify setup and programming alongside cobots.

- High-Speed Processing: Real-time image analysis enables cobots to operate at production line speeds without sacrificing accuracy.

- Robust Defect Detection: Advanced algorithms detect subtle defects that might be missed by human inspectors or simpler vision systems.

- Scalability: The system can be adapted to various applications, from small batch production to high-volume manufacturing.

These benefits make machine vision for collaborative robots an essential component of modern automation strategies.

Unlocking the Full Potential of Collaborative Robots and Machine Vision

The synergy between collaborative robots and machine vision for collaborative robots is transforming manufacturing across industries. By leveraging cobots with machine vision, companies can enhance precision, reduce errors, and increase operational flexibility. The KEYENCE VS smart camera exemplifies how cutting-edge vision technology empowers collaborative robot applications to deliver superior results.

Investing in cobots and vision systems is a strategic move for manufacturers aiming to stay competitive in today’s fast-paced market. With the right combination of robotics and vision, your production line can achieve new levels of efficiency and quality.

For more information on how KEYENCE’s VS smart camera can enhance your collaborative robot applications, contact us today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics