Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Static Control Solutions for the Automotive Industry

Static problems in automotive plants can drive up scrap, slow the line, and eat into margins. Whether it’s missed coatings or debris on high-gloss trim, charge buildup creates real friction from molding to final inspection.

Static electricity in automotive manufacturing is also a nuisance in everything from electronics assembly to paint finishing, where a single discharge can damage parts, attract dust, or disrupt automated equipment. With today’s vehicles carrying more electronics and tighter quality standards than ever, static control in automotive manufacturing is important to protecting both safety and productivity.

We’re here to provide you with more details.

Reach out today!

The Role of Electrostatic Discharge in Automotive Manufacturing

Electrostatic discharge (ESD) is a quiet failure point. One spark is all it takes to damage a PCB, throw off a sensor, or degrade the life of a control unit. And in most cases, it happens before anyone notices. Basic grounding steps help, but they don’t account for movement, friction, or handling off the bench. That’s where ionization comes in. It neutralizes charge at the air level, covering the gaps left by traditional ESD precautions.

Protecting Vehicle Electronics from ESD

The growth of electronics in vehicles has created a new front line in electrostatic discharge (ESD) safety in vehicle electronics. Modern control units, braking modules, and sensors use compact circuits that are highly sensitive to static discharge.

Industry standards such as ANSI/ESD S20.20 define practices for creating static-safe environments, but many automotive plants adopt stricter rules because components keep getting smaller and more sensitive. Building out ESD-protected areas and applying static control throughout the line reduces failures that might otherwise slip through initial testing and show up later in the field. Maintaining ESD safety in vehicle electronics is now a defining factor in reliable vehicle performance.

ESD Tools for Painting, Injection, and Finishing

Painting stages are vulnerable because static pulls dust onto panels, leaving shading or uneven coats. In molding, the charge on the cooling parts traps particles that affect both appearance and geometry. Sealing and finishing bring their own risk, with fibers sticking to charged surfaces and creating defects that slow the line.

Ionizers positioned along these stages provide active static charge removal. In paint booths, overhead systems or ionized air knives strip charge before dust can settle, reducing shading and overspray defects.

Static Control Challenges in Production Processes

Paint Shops and Bodywork

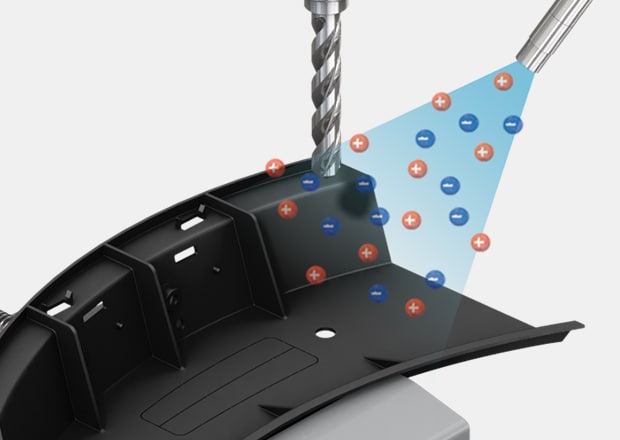

Bumpers don’t come out of the mold clean. As they move toward coating, charged surfaces attract airborne debris. Wiping each one slows down the line; even then, it’s no guarantee. An ionizer placed between molding and paint neutralizes the surface before particles can stick.

Electronics Assembly Lines

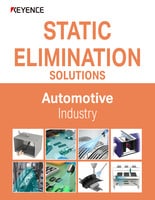

At every step of PCB production (when they’re handled, stacked, and moved), there is a chance to generate a charge. Ionizers placed above the line keep airborne voltage in check, reducing the risk of component degradation or latent faults.

Injection Molding and Packaging

Plastic picks up static charge fast. During cooling, ejection, and packing, that static can cause sticking, slowdowns, or even cosmetic defects. Ionizers clear the field, letting parts move freely and stay clean through to final packaging.

Discover more about this product.

Click here to book your demo.

Examples of Countermeasures in the Automotive Industry

Preventing Plastic Parts from Adhering to Molds

Molded parts generate static electricity very easily, which can cause them to stick to the mold until they fall off later. This problem increases the cost in terms of time and money spent disposing of the defective parts and removing them from the mold. An ionizer can eliminate this problem.

Preventing Electrostatic Destruction of Electronic PCBs

Static electricity is generated by debonding and friction when using PCBs. Even when grounding and other countermeasures are taken, they are usually inadequate. An ionizer can make static electricity countermeasures significantly more effective.

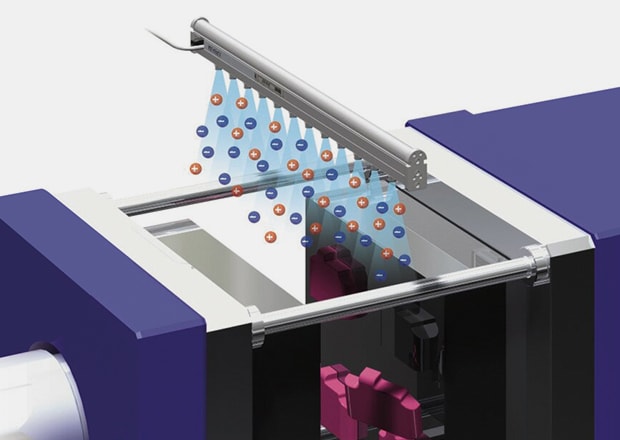

Preventing Adhesion of Trim Waste

When a plastic part, such as an instrument panel, is cut, waste material from this process remains attached to the part. To avoid potential damage, this waste must be blown off – an air-supplied ionizer can do just that.

Eliminating Static Charge During Bumper Coating

After a bumper is cast, foreign particles can adhere to it when it is transported to the coating process. Wiping bumpers so that they are clean enough to meet coating quality standards is time-consuming and laborious. In the worst-case scenario, bumpers may even have to be disposed of as a result of foreign particles. This problem can be avoided with an ionizer.

Problems Caused by Static Electricity and Improvement Examples

Benefits of Industrial Static Control Applications

Improved Product Quality

Production lines get sharper when parts stop attracting debris and components stop getting zapped; paint lays flat, PCBs pass tests, and products ship clean.

Fewer Defects and Downtime

Shaving seconds off of cycle times adds up. Removing static cuts down defect rates and rework hours. In some applications, downtime dropped 25% just by eliminating charge in the right spot.

Better Compliance and Worker Safety

Some processes use solvents and sprays. Add static, and you introduce ignition risk. Ionizers reduce that risk at the source while helping lines hit cleanliness and traceability standards.

KEYENCE Static Control Solutions for Automotive Lines

In automotive plants, static can be managed in several ways, but ionizers are the most effective across electronics, paint, and final assembly. The SJ-Q Series provides compact, localized discharge control at electronics workstations, while the SJ-E Series neutralizes charge across conveyors and paint booths where wide coverage is required. For larger bodies and assemblies, the SJ-H Series provides high-output static charge removal across extended zones. Together, these solutions create comprehensive static control in automotive manufacturing from component assembly to final vehicle finishing.

Upgrade your auto plant with smart ESD controls by implementing KEYENCE ionizer solutions! All hardware is designed to protect electronics, improve coatings, and keep assembly lines free from costly static defects. Contact us today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Does Static Affect Sensor Calibration in Cars?

Static discharges can alter sensor readings, leading to reduced accuracy and potentially shortening the sensor's lifespan over time.

Can ESD Exposure Impact Long-Term Vehicle Safety?

Yes. Latent damage to control units or safety electronics may lead to failures well after production.

What Systems Are Most Vulnerable to Static in EVs?

Battery management systems, Ethernet-based communications, and ADAS sensors are particularly susceptible to static, as they rely on precise data for optimal performance.

We’re here to provide you with more details.

Reach out today!