Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

ESD Prevention in Automotive Headlamp Manufacturing

Key Takeaways

- Static on resin headlamp parts attracts dust, causing rejects and undiscoverable internal contamination.

- Traditional humidity or sprays are unreliable; passive devices fail in high-speed, enclosed lines.

- KEYENCE ionizers neutralize charge in real time (bar, nozzle, air-free models) to prevent ESA/ESD.

- Proper ionizer selection (range, precision, continuous monitoring) lowers rejects and total cost.

In automotive headlamp production, static buildup is a direct threat to product quality and reliability. In this article, learn how KEYENCE static ionizers can prevent ESD & ESA in your process.

The Impact of Static Electricity on Headlamp Assembly

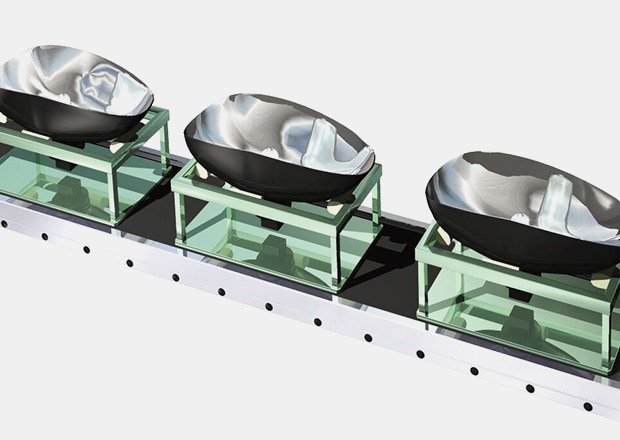

In automotive headlamp production, static buildup is a direct threat to product quality and reliability in modern automotive static control environments. Lightweight plastic components used in reflectors, housings, and lenses are highly susceptible to electrostatic charge, particularly during dry seasons or high-speed assembly operations. That charge attracts airborne particles, such as dust and fibers, into the headlamp unit.

*Headlamp unit: a unit in which a headlamp, turn-signal lamp and other components are assembled together

We’re here to provide you with more details.

Reach out today!

Common Sources of Static in Assembly Lines

Static forms during routine actions: plastic parts sliding against fixtures, workers removing components from trays, or lenses placed into housings. Friction, separation, and induction all contribute to static electricity in automotive manufacturing. In headlamp assembly, that means static can appear at multiple points across the line.

Increasing numbers of automotive parts are made of resin to reduce vehicle weight. Many resin parts are also used in headlamps. If resin parts are charged with static electricity and dust or other foreign particles adhere to them, the dust may enter inside the headlamp during assembly.

When entry of dust is discovered after assembly of the headlamp unit, the entire unit must be disposed of because it cannot be disassembled, resulting in a large loss.

Conventional Countermeasures and Their Limitations

Traditional anti-static measures, like humidity control or anti-static sprays, rarely hold up in the fast-paced, clean-sensitive conditions of automotive lighting assembly. Moisture-based methods introduce condensation risks, while chemical sprays require reapplication and may create surface residues.

Passive devices, such as tinsel, brushes, and cords, are beneficial in slower-moving environments, but they’re no match for multi-axis robot arms or compact assembly enclosures.

Conventional Countermeasures

Humidity control

- The effect is uncertain.

- Condensation may occur.

Countermeasures with Static Eliminators (Ionizers)

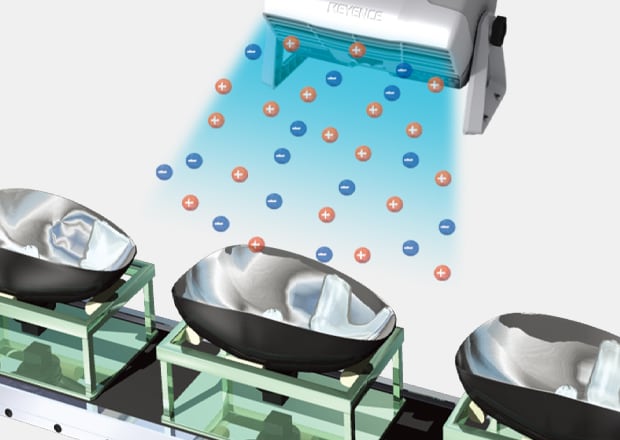

An ionizer prevents the entry of foreign particles, which reduces the disposal cost of lamps.

[Improvements and Effects] Words from the worksite:

The disposal cost can certainly be reduced.

Impact on Quality and Safety

Every particle attracted by electrostatic attraction (ESA) carries risk. Dust on a lens can scatter light or reduce beam clarity, which means electrostatic discharge (ESD) protection for headlamp components can’t be an optional step. Charged surfaces can repel parts or cause plastic housings to shift during the bonding process. Even a low-voltage discharge can stress LEDs or printed circuit boards (PCBs) during alignment, potentially leading to latent defects that may go undetected.

Discover more about this product.

Click here to book your demo.

How Ionizers Effectively Prevent ESA in Headlamp Assembly

KEYENCE ionizers eliminate static charges by flooding the assembly environment with balanced streams of positive and negative ions. These ions neutralize surface charges on resin components, tools, and even operators’ gloves, preventing dust attraction and eliminating the conditions that allow ESA to interfere with placement or bonding.

Unlike passive or chemical methods, ionizers work in real-time. Models like the SJ-F700 utilize large volumes of air for long-range neutralization, while the SJ-H model offers an air-free solution for cleanroom environments.

Benefits of Using KEYENCE’s Ionizers in Headlamp Manufacturing

Manufacturers using KEYENCE systems report significant reductions in unit rejection rates and disposal costs. Integration is straightforward thanks to compact footprints, flexible mounting, and automation-ready interfaces. Many models feature anti-static solutions for vehicle lighting, including self-cleaning emitters, auto-balancing circuits, and onboard diagnostics.

These ionizers deliver static control without the need for external air compressors or added consumables, and they help lower the total cost of ownership while supporting lean, dust-free production environments.

KEYENCE Static Control Solutions for Automotive

Headlamp production is just one of many use cases where KEYENCE static control systems excel. Bar-type ionizers cover wide working areas, ideal for conveyors or resin prep, and nozzle ionizers provide pinpoint accuracy for lens seating, bonding, or seal inspection. Units like the SJ-LG deliver fast charge neutralization even in confined spaces without disturbing delicate components.

Explore KEYENCE’s full ionizer lineup for ESD prevention to find the right fit for your process, whether you're dealing with lighting, instrument panels, coatings, or electronics.

How to Choose the Right Static Control Solution for Your Production Line

Different production steps require different ionization strategies. High-speed lines benefit from bar-style systems with long-range ion delivery. Compact stations with robotic assembly tools need local, precision units that won’t disturb part alignment or airflow. Environments with high dust sensitivity may require continuous ionization paired with monitoring sensors to maintain stable charge levels across shifts.

Protect headlamp assembly lines with reliable static control. Contact us today to get started.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can ESD Damage Affect LED Headlamps During Assembly?

Yes. Even low-energy discharges can weaken or destroy LED drivers, PCB traces, or lens coatings. These failures often appear later, after vehicle installation.

How Often Do I Need to Clean or Maintain Ionizers?

KEYENCE ionizers are engineered for minimal upkeep. Most models feature self-diagnostic tools and emitter-cleaning alerts to help teams schedule quick, low-effort maintenance.

What are the Long-Term Benefits of Static Prevention in Auto Plants?

Reliable static control reduces rejection rates, improves product quality, and prevents rework. Over time, this leads to fewer disruptions, lower scrap costs, and improved process reliability.

Can Ionizers Be Used in Other Automotive Manufacturing Processes?

Absolutely, ionizers support static removal during injection molding, painting, inspection, and packaging.

We’re here to provide you with more details.

Reach out today!

![Examples of Applications by Process [Automotive Edition] Vol.05](/img/asset/AS_158360_L.jpg)