Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Resin Film Static Control Solutions

Key Takeaways

- Static builds at roller transfer points, causing cling, drifting lanes, trapped film and dust attraction.

- Thin/multilayer polypropylene and PET hold charge longer, increasing misalignment and defect risk.

- Industrial ionizers (balanced ions) positioned at unwind/transfer/rewind neutralize surface charge at the source.

- Fast, high-output ionization stabilizes web tension and reduces scrap, lowering recall and disposal costs.

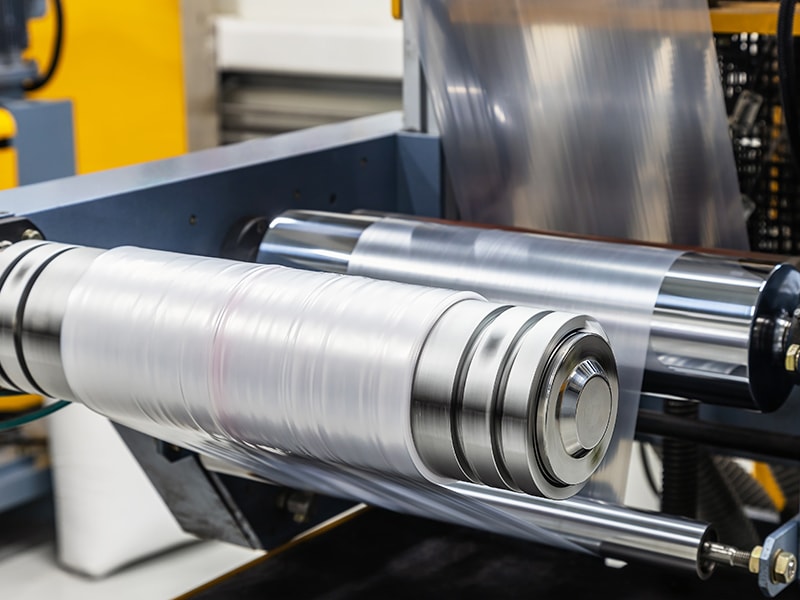

Resin film moves across rollers at high speed, and each point of contact adds charge to the surface. Thin films and multi-layer structures hold this charge longer than most materials, which makes them prone to cling, attraction, and misalignment. Static control in resin rolls keeps production stable by reducing the forces that pull film toward rollers or cause sheets to stick to themselves.

Resin manufacturing lines also handle polypropylene, PET, and similar films that carry a charge for long periods, so it often builds faster than it can be dissipated. As equipment speeds up and paths become more complex, even slight fluctuations in surface charge can influence behavior. Fortunately, using an industrial ionizer can remedy this issue, supporting consistent transfer and reliable yield across long runs.

The Impact of Static on Resin Rolls in Production

Static forms whenever a film touches and separates from a roller. The charge builds as the web passes from unwind to chill roller to rewind, and each transfer point adds another opportunity for imbalance. These static issues show up as cling during roll transfer, drifting edges, trapped film, or sheets that pull toward the roller face instead of releasing cleanly. Charged surfaces also draw in dust from the surrounding area, which marks the film and disrupts downstream bonding or coating steps.

On high-speed equipment, film movement becomes more sensitive to charge. A slight electrostatic pull can cause a web to tug off-track or stick to a roller surface at the wrong moment. The trapped area then wrinkles or stalls, leading to defects that carry through the roll. Because resin manufacturing depends on steady web tension and uninterrupted movement, static control in resin rolls plays a central role in maintaining flow.

Conventional Countermeasures

Conventional Static Eliminator

The effect is insufficient and varies depending on the diameter of the roll.

It cannot improve the quality.

We’re here to provide you with more details.

Reach out today!

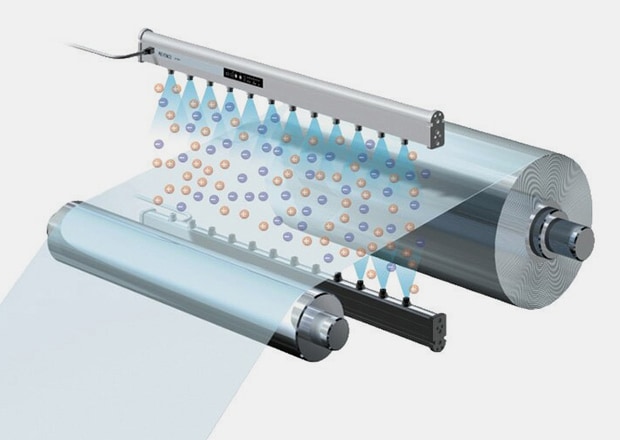

Countermeasures with Static Eliminators (Ionizers)

An ionizer can avoid complaints about defective products and improve quality.

Reduced Cost for Preventing the Release of Defective Products

Disposal cost of $30,000/year + Recall cost (transportation and on-site service travel costs) of $10,000/year = $40,000/year

Films with higher added values will be produced in the future. If no measures are taken, there will be a risk of further damage.

How KEYENCE Ionizers Eliminate Static in Resin Rolls

An industrial ionizer, like the SJ-Q from KEYENCE, addresses charge at the source by delivering balanced ions directly into the web’s path. When positioned at points where charge builds (unwind stations, transfer rollers, or the final rewind), the ionizer neutralizes the field that pulls the film off its correct trajectory. This stabilizes the way the film releases, floats, and settles as it moves between rollers.

KEYENCE ionizers match the needs of resin manufacturing environments where film thickness varies and roller spacing shifts during long runs. High-output ion generation maintains coverage across wide webs and curved paths without forcing operators to slow the line. Their steady ion balance helps the film release cleanly, even at higher speeds where static forms rapidly.

During rapid transitions between rollers, charge levels can change within milliseconds; fast ion delivery keeps the film from lifting or drifting as it enters the next stage. Broad coverage also supports wide or multi-lane webs that accumulate charge unevenly across the width. This combination gives production teams a dependable way to manage static during roll-to-roll movement without frequent adjustments or changes to the line setup.

Preventing Resin Roll Defects with Static Control

Static issues in resin manufacturing lead to repeated defects when the web cannot separate cleanly or when dust lands on a charged surface. Charged film may cling to a blade after cutting, shift during winding, or pull toward a roller at an unexpected moment. These disruptions introduce marks, wrinkles, curled edges, and small surface flaws that show up during inspection.

By applying resin roll static elimination at the points where film charge builds most often, production teams cut down on these interruptions. Neutralization reduces attraction forces and helps the film fall, feed, and wind the same way every time. This stabilizes web tension, supports uniform coatings, and minimizes scrap caused by contamination or misalignment. With charge consistently controlled, operators spend less time clearing trapped film or correcting drift and more time running at target speed.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Problems Can Static Cause in Resin Roll Production?

Static issues appear as film cling, trapped edges, drifting lanes, dust attraction, and inconsistent release from rollers. These problems disrupt winding, cutting, coating, and bonding steps.

How Do KEYENCE Ionizers Improve Resin Roll Manufacturing?

They reduce charge along the film path, support steady transfer, and help prevent contamination and misalignment.

What Makes KEYENCE’s Static Control Solutions Stand Out in Resin Manufacturing?

KEYENCE ionizers deliver fast, balanced ion output that supports consistent handling on high-speed resin lines.

We’re here to provide you with more details.

Reach out today!