Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Resin Parts Static Control Solutions

Key Takeaways

- Static forms at contact/separation points, causing cling, jams, misalignment and scrap.

- Thin/multilayer resin and film retain charge longer, increasing defect and contamination risk.

- Ionized pulsed air or industrial ionizers neutralize charge at source, improving part release.

- Real time feedback ionizers stabilize throughput, reduce rework, and lower disposal costs.

Resin parts move through fast and varied production environments, and any buildup of surface charge can disrupt that movement. Charge forms quickly on molded parts, cut surfaces, and resin film as they pass across tools and transfer points. Resin scrap static control plays a key role in keeping these processes stable. By limiting the conditions that cause buildup, manufacturers maintain consistent part release, steady film motion, and higher yield across long runs.

Static’s Role in Resin Scrap Defects and Waste

Resin carries charge easily because it behaves as an insulator. During molding, cutting, trimming, or roll transfer, each point of contact and separation adds more charge to the surface. Thin parts and multi-layer films hold that charge longer, so electrostatic-driven behavior becomes more noticeable as the line runs. Sticking during mold release, feeder bowl jams, drifting edges during winding, or film that pulls toward a blade can all trace back to charge accumulation. These outcomes feed directly into preventing resin scrap defects, since even small disruptions cause trapped pieces, flawed surfaces, or contaminated parts that cannot move downstream.

Dust attraction is another consistent issue. Charged resin pulls airborne particles toward its surface, and those particles attach firmly enough to interfere with bonding, printing, sealing, and inspection. This type of contamination contributes to scrap even when the part appears clean at first glance. Static elimination in these environments removes the conditions that lead to cling, misalignment, and particle attraction, forming the base of any reliable resin-focused quality strategy.

Conventional Countermeasures

Air blow

- Cannot eliminate static electricity, actually increases the charge.

- Cannot remove foreign particles completely.

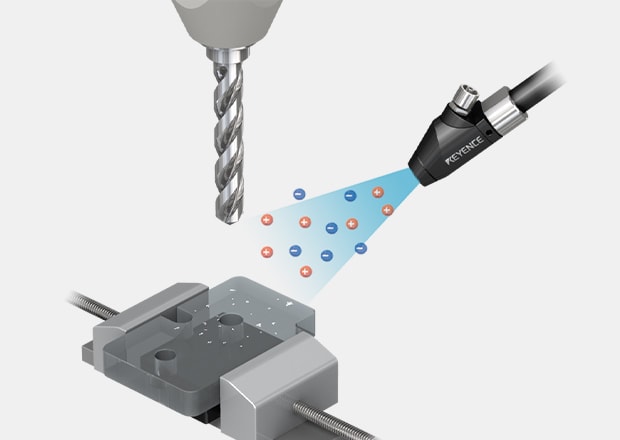

Countermeasures with Static Eliminators (Ionizers)

Ionized pulsed air blows off foreign particles. An ionizer can reduce the defects caused by foreign particles and improve the yield rate.

Reduced Disposal Cost Due to Foreign Particles

Disposal cost due to foreign particles: $500/month × 12 months = $6,000/year

In addition, there are other resulting benefits of improved reliability.

We’re here to provide you with more details.

Reach out today!

How KEYENCE Ionizers Combat Static in Resin Scrap

Industrial ionizers neutralize charge on resin parts by applying balanced ions right where the material moves through molding, cutting, or automated handling. When the charge dissipates at the point where it forms, resin parts fall cleanly from molds, swarf lifts away instead of clinging, and film maintains a stable path across rollers or guides. These results support preventing resin scrap defects by limiting the trigger conditions that create sticking, chipping, and contamination.

KEYENCE ionizers, like the SJ-Q, are built to maintain steady performance in production environments where resin moves rapidly and surfaces shift shape or position. High-output pulse AC ion generation supports fast static elimination across large areas, while the airflow design keeps ion distribution even across complex geometries. Models with feedback and monitoring functions help operators see charge conditions in real time, tightening overall control of resin scrap behavior. Durable emitters, protective structures around ionizing points, and low-maintenance components support continuous operation during long runs.

Enhancing Production Efficiency with Static Control

Manufacturing efficiency improves considerably when static stops influencing the movement of resin parts. Uncontrolled charge introduces delays across many stages: parts remain in molds longer than planned, feeder bowls jam more frequently, and film handling equipment must slow down to reduce cling. Each interruption adds to rework, inspection time, and operator involvement. Static elimination removes these friction points, allowing equipment to run at designed speeds without the sudden behavior changes that come with high charge levels.

Cleaner part release and stable film motion also support consistent downstream operations. When resin parts leave the mold without sticking, packaging and assembly equipment run with fewer pauses. When film does not pull toward a blade or roller, tension remains stable and alignment stays accurate. All of these factors increase manufacturing efficiency by limiting waste, reducing adjustments, and helping teams keep the line moving without unexpected variation. Industrial ionizers contribute to this outcome by sustaining balanced surface conditions as each part moves through the line, which reduces scrap and stabilizes throughput.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Does Static Contribute to Resin Scrap in Production?

Static makes resin parts cling, pull in dust, or drift during transfer. These behaviors create surface flaws, jams, and alignment issues that turn usable parts into scrap.

What Are the Benefits of Using Static Eliminators for Resin Scrap?

Static eliminators neutralize charge so parts release, move, and handle cleanly. This lowers defects tied to cling, contamination, and misfeeds.

How Do KEYENCE Solutions Help Reduce Resin Scrap in Manufacturing?

KEYENCE ionizers deliver fast, balanced ion flow that keeps resin surfaces stable, film paths in control, and, overall, decreases scrap across long production runs.

We’re here to provide you with more details.

Reach out today!