Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

Static Control Systems for Molded Resin Parts

Key Takeaways

- Static on resin parts causes sticking, particle attraction, and ejection failures.

- Neutralize charge at mold open/release with ionizers to reduce scrap and interruptions.

- Bar-type ionizers (SJ-Q, SJ-H) mount at openings, ejector zones, or drop paths for fast elimination.

- Compact, high-output ionizers reduce manual removal, double-closing risk, and conveyor jams.

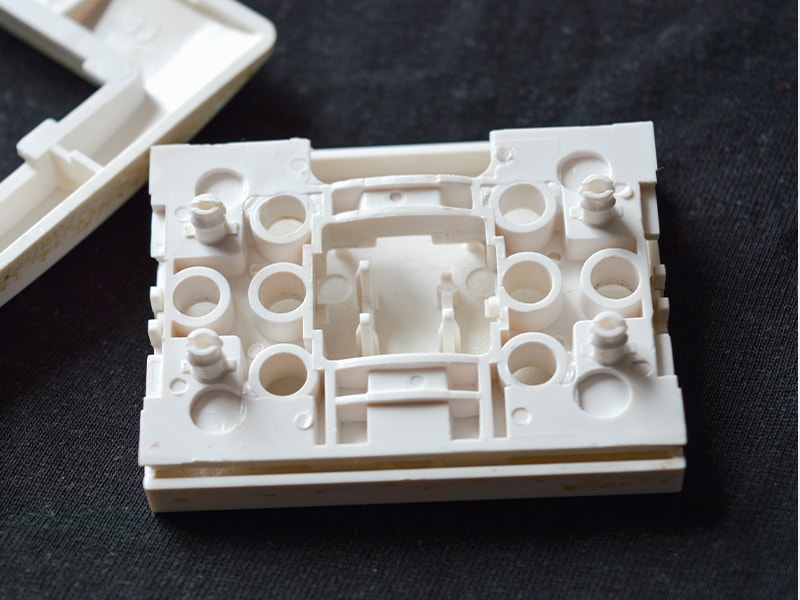

Molded resin parts move through fast cycles, tight cavities, and complex ejection paths. As these parts separate from the mold, static charge accumulates and influences how they release, how they fall, and how they are handled downstream. Resin mold static control using ionizer technology is a need in manufacturing environments where sticking, particle attraction, and repetitive interruptions limit molding quality and flow.

How Static Affects Resin Molding and Product Defects

Static in manufacturing is common whenever plastics move, rub, or separate at speed. Molded resin parts experience all three conditions during injection, cooling, and ejection. Friction with the mold wall creates a charge on the part surface, and as modern parts become thinner and lighter, they hold that charge longer. Complex geometries increase the surface area in contact with the mold, which heightens static buildup and makes sticking more frequent. High-speed injection also raises the charge level and increases the likelihood of a part remaining in the mold.

These static forces lead directly to mold defects. Parts cling to the mold face, stay lodged on ejector pins, or remain inside the cavity. When parts do not fall cleanly, they disrupt cycle timing and create a risk of double-closing on a trapped piece. Surfaces charged during release attract airborne particles and dust, which creates cosmetic defects that show up immediately or later. When parts accumulate in totes, the collective charge builds into a larger field that draws in more contaminants and creates unpredictable handling.

Static elimination in molding addresses these issues at the source. Neutralizing the charge during mold opening, part release, and early handling ensures a reliable part flow that is less susceptible to changes in geometry, weight, or ambient conditions. This sets the foundation for higher yield and stable part quality.

Conventional Countermeasures

Measure Against Defects Caused by Foreign Particles: Provide a Cover.

The effect is small.

Measure Against Remaining Parts: Install a Sensor.

The sensor can only detect the occurrence of remaining parts. The parts must be removed manually.

We’re here to provide you with more details.

Reach out today!

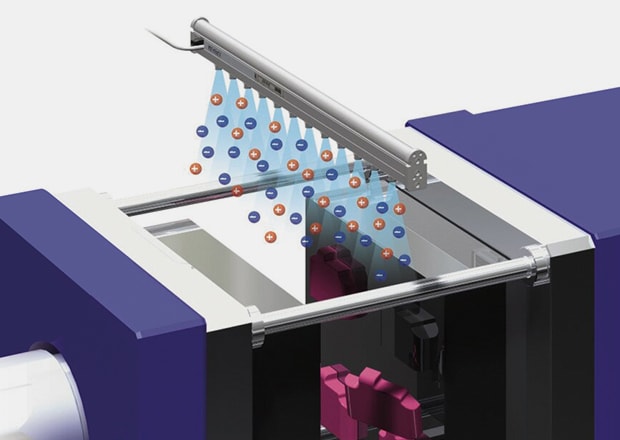

Countermeasures with Static Eliminators (Ionizers)

An ionizer eliminates static electricity to prevent the adhesion of foreign particles and remaining parts. It can reduce waste of material costs and improve the yield rate.

Reduced material disposal cost due to defects caused by foreign particles

Material cost: $10 × 200 pieces/month × 12 months = $24,000/year

Since remaining parts may lead to a risk of mold breakage due to double closing, the measure is also effective for reducing the cost of equipment maintenance.

KEYENCE ’s Approach to Static Control for Resin Molding

Conventional approaches, like covers or optical sensors, only react to sticking after it disrupts the molding process. These methods do not influence the static conditions that cause the failure in the first place. Ionizer technology changes the environment around the mold by neutralizing the charge that develops during molding, release, and early transfer.

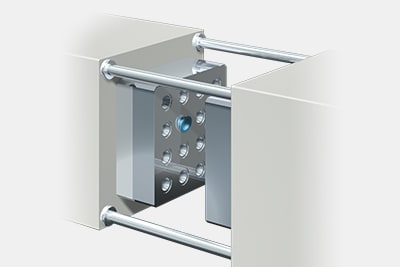

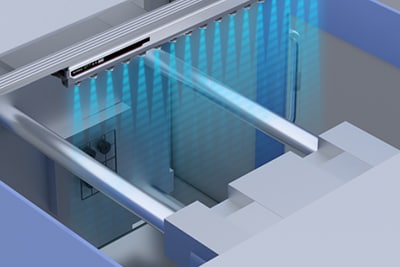

KEYENCE bar-type ionizers, such as the SJ-Q and SJ-H, can be mounted at the mold opening, across ejector zones, or along the initial drop path to provide fast static elimination in molding. Discharging the part as it separates from the mold supports resin mold static Control by limiting sticking and reducing particle attraction. When lightweight parts require a clear fall path, these ionizers stabilize movement around conveyors and catch bins. In areas where electrostatic charges build as parts accumulate, compact units maintain a neutral field that keeps flow steady without adding complexity to the cell.

KEYENCE systems are built for molding environments where space is limited, maintenance windows are short, and production is continuous. High-output static elimination, long-range performance, and reduced buildup on electrode probes support consistent operation without frequent intervention. These characteristics make resin mold static control an integrated part of the molding cell rather than an afterthought.

The Benefits of Ionizers in Resin Mold Manufacturing

Ionizer technology directly addresses the causes behind sticking, particle adhesion, and unstable ejection. When static is neutralized, molded parts release more predictably, which reduces manual removal and lowers the possibility of mold damage from double-closing.

Stable release also supports cycle repeatability. Parts fall cleanly into bins, and ejector clogging becomes less common. Conveyors run with fewer interruptions because parts do not cling to belts or sidewalls.

These gains add up across long production runs. Reduced scrap lowers material spending, fewer line interruptions shorten cycle times, and cleaner surfaces reduce rework. Ionizers bring consistency to processes shaped by friction, speed, and part geometry, giving molding teams a practical way to manage static in manufacturing environments.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Does Static Affect Resin Mold Goods?

Static causes parts to stick, attract dust, and move unpredictably during ejection and early handling.

What Are the Benefits of Static Control in Resin Molding?

Static control reduces sticking, lowers scrap, and keeps molded surfaces cleaner throughout the process.

Can KEYENCE Ionizers Eliminate All Mold-Related Defects?

Ionizers eliminate defects rooted in static charge, while issues unrelated to static depend on tooling and process conditions.

We’re here to provide you with more details.

Reach out today!