Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- 2D Measurement Inspection

- Optical Character Reading (OCR) and 1D/2D Code Verification

- Inline 3D Volume and Measurement Inspection

- Presence & Absence Inspection

- Flaw Detection

- 3D Vision-Guided Robotic Bin Picking

- High-Resolution Line Scan Cameras for High-Speed Imaging

- Automated Positioning and Alignment Systems Using Machine Vision

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace

Different Types of Machine Vision Systems

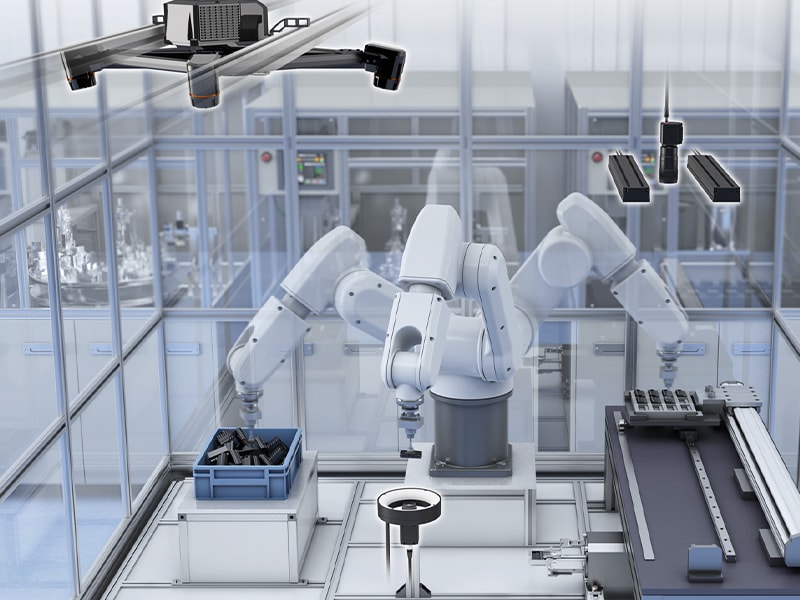

Machine vision systems have emerged as an essential component of contemporary manufacturing and industrial automation. Cutting-edge imaging technology, in conjunction with machine learning and artificial intelligence, powers these systems to analyze environments and objects with precision. Machine vision systems improve production lines' speed, efficiency, and consistency by taking the place of manual inspections.

Advantages such as these have led to diverse applications and have revolutionized many processes because of their precision and automation capabilities.

Overview of Types of Machine Vision Systems

Machine vision systems are incredibly accurate, allowing for precise measurements and the detection of minute flaws. Their fast speed, which enables them to process thousands of items per minute on high-speed production lines, makes them indispensable in hectic environments. Additionally, by seamlessly integrating with existing equipment, such as robots and conveyors, these systems increase operational efficiency.

Continuous improvements in machine vision have led to two types of machine vision systems: two-dimensional and three-dimensional. The task's complexity, the kind of data needed, and the level of detail required for analysis all influence which option is best.

2D Machine Vision Systems

2D machine vision systems use bidimensional images to analyze objects based on their length, width, and surface characteristics. Systems rely on lighting, cameras, and software algorithms to detect visual differences and patterns. The capabilities of 2D systems make them indispensable for many straightforward inspection tasks, including these everyday use cases:

- 1. Food Packaging Inspection: Ensures that labels are correctly applied and checks for tears or contaminants on the film.

- 2. Electronics Assembly: Verifies the placement of microchips and resistors on circuit boards.

- 3. OCR Verification and Character Inspection: Reads printed expiration dates, batch codes, or serial numbers with high accuracy.

2D systems are perfect for simple inspection requirements and are generally easy to use for a variety of applications.

Despite their widespread use, 2D systems do have limitations. They cannot measure depth or analyze three-dimensional shapes, which is where 3D machine vision systems shine.

3D Machine Vision Systems

A 3D Inspection and Measurement Vision System provides depth perception and dimensional data by capturing three-dimensional images. 3D systems utilize multiple cameras, structured light, or laser triangulation to create a detailed 3D map of an object. Common use cases include:

- 1. Automotive Industry: Inspects engine parts for precise dimensions and verifies their assembly.

- 2. 3D Inspection and Measurement: Evaluates the flatness of surfaces or detects warping in metal sheets.

- 3. Logistics: Scans packages to determine their volume for automated sorting.

For examining intricate geometries and objects at different depths, 3D systems are perfect. Detailed information on height, volume, and contours is provided, which helps to understand the quality of the product better. For sectors like aerospace and medical devices that have strict quality control requirements, these systems are a necessity.

2D and 3D systems complement one another and enable manufacturers to address a range of challenges.

Discover more about this product.

Click here to book your demo.

Applications of Machine Vision Systems

Industrial machine vision types are highly versatile, with applications tailored to meet the unique demands of specific industries. Let's examine a few important uses, emphasizing the advantages of the different types of machine vision systems.

Defect Detection

Defect detection ensures that only high-quality products leave the production line. This application involves identifying visual flaws like scratches, dents, discoloration, or cracks. In the pharmaceutical industry, for example, machine vision systems inspect blister packs to detect missing pills or damaged packaging. Similarly, in the automotive sector, these systems spot surface defects on painted car parts. Early defect detection reduces waste, prevents recalls, and maintains brand reputation.

Positioning

During manufacturing processes, positioning entails directing machinery, like robotic arms, to exact locations. To guarantee precise handling, machine vision systems determine an object's precise location and orientation. Various types of machine vision systems are used in electronics manufacturing to assemble parts like chips and connectors with sub-millimeter accuracy. This is especially important for high-density printed circuit boards (PCBs). Accurate positioning reduces errors and improves production efficiency.

Presence/Absence Detection

This application verifies whether all components of a product are present or correctly placed during assembly. In the automotive industry, presence detection ensures that every bolt, screw, or gasket is correctly installed in an engine assembly. Similarly, in consumer goods, it checks that every item, such as a straw or condiment packet, is included in packaged products. It ensures complete products are delivered to consumers, avoiding dissatisfaction or safety issues.

Measurement

In sectors where strict tolerances are unavoidable, such as electronics and aerospace, precise measurement is essential. Machine vision systems measure dimensions such as length, width, height, and angles with incredible accuracy. A Vision Measurement for Dimension Inspection system ensures that machined parts meet exact specifications before assembly. It reduces variability, ensures regulatory compliance, and improves product functionality.

Optical Character Recognition (OCR)

OCR enables machine vision systems to read printed or etched characters on products and packaging, such as serial numbers, expiration dates, or lot codes. In pharmaceutical packaging, machine vision ensures that expiration dates are clearly printed and legible, enabling regulatory compliance and enhancing traceability. OCR Verification and Character Inspection systems excel at recognizing text even on challenging surfaces. OCR increases traceability and eliminates the risk of misprinted information.

We’re here to provide you with more details.

Reach out today!

Choosing the Right Machine Vision System

Machine vision systems are indispensable, providing unparalleled accuracy and efficiency. Whether you are addressing surface-level inspections with 2D machine vision systems or tackling complex geometries with 3D vision systems, the right technology will improve your production process. For applications like defect detection, dimensional measurement, and OCR, these systems ensure compliance, quality, and cost savings.

But with the different types of machine vision available, which system is best for your needs? Selecting the appropriate types of machine vision equipment depends on several factors:

- 1. Complexity of the Task: For surface-level inspections, 2D systems usually suffice. For depth measurements or complex geometries, 3D systems are necessary.

- 2. Production Speed: High-speed production lines may require faster imaging and processing capabilities.

- 3. Environmental Conditions: Harsh environments, such as those with high temperatures or dust, may require ruggedized systems.

KEYENCE is a leader in innovative types of machine vision systems, offering cutting-edge hardware, AI-powered tools, and comprehensive solutions to meet any manufacturing inspection need.

Contact us today to speak with a specialist.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Applications

- 2D Measurement Inspection

- Optical Character Reading (OCR) and 1D/2D Code Verification

- Inline 3D Volume and Measurement Inspection

- Presence & Absence Inspection

- Flaw Detection

- 3D Vision-Guided Robotic Bin Picking

- High-Resolution Line Scan Cameras for High-Speed Imaging

- Automated Positioning and Alignment Systems Using Machine Vision

Industries

- Automotive

- Automation Equipment/Machine Building

- Electric Vehicles

- Medical Device Manufacturing

- Food/Beverage Packaging

- Semiconductor/Manufacturing Electronics

- Vision-Guided Robotics

- Solar

- Logistics

- Commodities

- Paper Manufacturing

- Machine Tools

- Electronic Device

- Printing

- Mining/Metals

- Fabric/Textile

- Tobacco

- Marine

- Aerospace