Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

Edge Learning in Machine Vision Systems

Unlike deep learning machine vision systems that require heavy computing power and centralized training, edge learning takes place directly on the device, at the "edge" of the network. This localized processing dramatically reduces latency, simplifies integration, and enables vision systems to adapt in real time with minimal setup. For production teams facing increasing demand for flexibility and precision, edge learning offers a practical, deployable AI solution that accelerates decision-making on the factory floor.

What is Edge Learning?

Edge learning is a form of artificial intelligence that runs directly on the vision system itself. Rather than sending data to a remote server or cloud environment for processing, edge learning models analyze images locally using pre-trained algorithms. This architecture allows decisions to happen closer to where the data is generated, or at the ‘edge’ of the network.

Edge learning makes machine vision more accessible without deep learning expertise. Models can be trained in minutes using only a handful of representative images, and processing is done entirely on the device, which eliminates the need for external computing infrastructure.

This simplicity speeds up deployment and reduces downtime during product changeovers, and gives it extensive benefits in applications like manufacturing, where visual inspection can still be used for identifying defects or classifying products.

We’re here to provide you with more details.

Reach out today!

Why Edge Machine Learning is a Game-Changer for Manufacturing

Scenarios Best Suited for Edge Learning

Edge learning is ideal when deployment speed matters and when the inspection criteria are relatively stable. If a production line frequently changes SKUs or if it is working with consistent product orientation, edge learning can give manufacturers the ability to move quickly without sacrificing performance. Edge machine learning allows:

- On-device processing (no cloud reliance)

- Real-time decision-making

- Faster setup and ROI

Industries Benefiting from Edge Learning

- Food & Beverage: e.g., classifying tray contents on frozen meals and label placement

- Electronics: managing frequent design changes, new parts, and identifying defects

- OEMs and System Integrators: rapid feasibility studies and deployment

- Automotive: catching defined defects on complex materials where the color, reflection, and texture may not always be consistent

Scenarios Best Suited for Deep Learning (and Why We Don’t Need to Use It)

Deep learning becomes necessary when inspection complexity exceeds what traditional or edge systems can handle. This includes detecting cosmetic flaws that vary widely, verifying assemblies with irregular part geometries or working in environments where lighting and orientation introduce variability that simpler systems can’t resolve.

The caveat is that it needs thousands of images to work effectively, and significantly increases the deployment time, which disqualifies it from many applications where time and money are a priority.

Edge learning on the KEYENCE VS Series smart camera bridges the gap between high-performance vision and easy deployment. With edge AI running directly on the device, the VS Series delivers fast learning cycles, minimal setup, and robust inspection accuracy—all within a compact, scalable solution.

Edge Learning vs. Deep Machine Learning: When Less is More

Deep learning applies layered neural networks to large image datasets that identify patterns and anomalies. These models are not taught what to look for explicitly, instead learning by analyzing hundreds or thousands of examples labeled ‘good’ or ‘defective.’ Due to the complexity involved in training these models, deep learning systems usually require powerful hardware like GPUs or access to cloud computing.

The drawback is that the processing time, both during development and runtime, can be considerable; thousands of labeled images are needed, and expert data scientists must be involved to make sure everything works correctly.

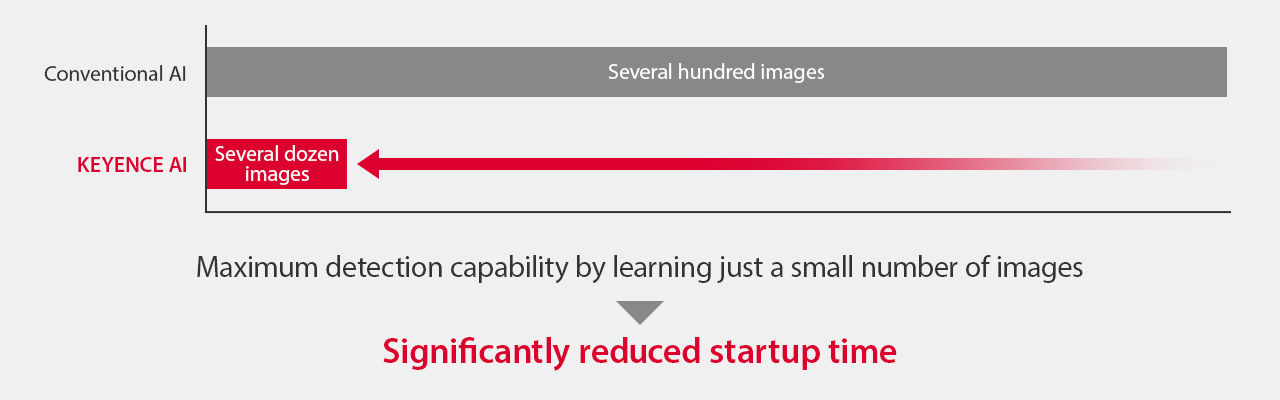

Number of images required for learning before operation

Interfaces and Connectivity Options

Edge machine learning systems are often deployed with smart cameras, which integrate sensors, processors, and I/O into a single unit. They can use as few as five to 10 images, can be configured by operators or engineers (non-experts), and deployed within hours or days.

The VS Series is a good example, combining edge learning tools with flexible connectivity. These cameras typically support industrial protocols such as Ethernet/IP™ or PROFINET, making it easier to connect with PLCs, HMIs, or other control devices without needing a separate processing unit.

Software Compatibility

Most edge-enabled vision systems come bundled with software that supports drag-and-drop model creation, quick retraining, and no-code interfaces. These platforms are designed to work with minimal setup and are often compatible with broader automation software environments, which maintain production speed and flexibility.

Deep learning systems, on the other hand, may require external training or cloud-based tools to develop and deploy their models.

Get detailed information on our products by downloading our catalog.

View Catalog

Key Benefits of Edge Learning Solutions for Manufacturers

Processing Speed

Edge learning systems are designed for speed, with training typically completed within minutes and models running in real time. In contrast, deep learning requires longer training time, ranging from several hours to days, depending on image set size, model architecture, and compute resources.

Computational Requirements

Deep learning typically requires more structurally sound infrastructure for both training and inference, often involving GPU-equipped servers or cloud access, unless they are optimized with techniques in quantization or knowledge distillation. Edge learning is lightweight; a smart camera with onboard processing is usually enough.

Accuracy and Learning Curve

Deep learning excels at identifying subtle or highly variable defects, especially when the visual criteria are hard to define manually. However, the learning curve is steep, and model management is more involved.

Reduced Complexity and Costs

Edge learning dramatically lowers both the technical and financial barriers to entry. It simplifies system architecture and reduces the need for external infrastructure, cutting down on both CapEx and OpEx.

Enhanced Uptime Through Simplified Retraining

With minimal training data and no need for a specialist to tune the model, manufacturers can troubleshoot or update inspections without pulling in a data science team, keeping lines moving with minimal interruption.

The Future of Machine Vision is at the Edge

Edge learning represents a major step forward in making AI-powered vision systems faster, easier, and more accessible. For manufacturers who want to move quickly, reduce costs, and remain agile in an increasingly automated world, edge learning is the future of inspection.

Explore how edge AI can unlock new levels of performance in your production line. Contact us today for a demo or consultation.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can Edge Learning Work With Any Industrial Machine Vision System?

Edge learning requires a system with onboard AI processing. Most smart cameras designed for factory automation support it out of the box.

How Does the Cost of Implementing Edge Learning Compare to Deep Learning in Machine Vision?

Edge learning is generally less expensive. It requires less hardware and fewer images, and it can be deployed and managed by in-house teams without outside expertise.

Can Edge Learning Be Used in Environments With Limited Internet Connectivity?

Yes. All training and inference occur on the device, making edge machine learning ideal for environments without consistent cloud or server access.

What Kind of Hardware Is Needed for Edge Learning in Machine Vision?

A smart camera with embedded AI capability is usually sufficient. No external GPU or PC necessary.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics