Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

Introduction to Machine Vision Programming: Basics, Applications & Benefits

Machine vision programming is transforming modern industry by allowing computers to see and interpret visual information. This technology helps businesses improve quality control, increase efficiency, reduce errors, and maintain a competitive advantage.

The Basics of Machine Vision Programming

How Machine Vision Programming Works

Think of machine vision as human vision, but it is much more consistent. The system captures images with cameras, processes them through algorithms, and makes decisions based on what it sees. Unlike humans, who get tired, machine vision systems are accurate regardless of the runtime.

Machine vision basics involve capturing images, improving image quality, finding areas of interest, and making decisions based on what’s detected. Modern systems can now use AI to learn from examples.

Key Components of a Machine Vision System

A machine vision system is made up of several parts that work together. High-quality cameras take the images for analysis; proper lighting ensures the photos are clear and shadow-free. The processing hardware processes the images, and the software interprets them to make decisions. The communication interfaces connect the vision system to other automation equipment, and the output devices execute the decisions.

Types of Sensors Used in Machine Vision

Different applications need particular sensors. Standard cameras capture full images at once, while line scan cameras build images line by line for moving objects. 3D sensors measure shapes by providing depth data, infrared sensors detect heat differences, and specialized sensors capture information not visible to standard cameras.

We’re here to provide you with more details.

Reach out today!

The Importance of Machine Vision in Automation

Enhancing Precision and Accuracy in Automation

Machine vision brings exceptional precision to automated processes, enabling measurements down to micrometers. This level of precision is necessary in industries like semiconductor manufacturing, where tolerances are extremely tight.

Reducing Human Error and Improving Efficiency

Human inspectors inevitably get tired, which can lead to missed details and inconsistent quality. Machine vision maintains the same high standards from the first product to the last. These systems also work much faster than humans can, allowing production lines to achieve both better quality and higher output.

Integration of Machine Vision with Robotic Systems

Vision-guided robots adjust their movements in real time when they detect changes in position or product variations. This flexibility allows a single production line to handle multiple product types without the need for reconfiguration, resulting in more versatile manufacturing systems.

Common Applications of Machine Vision Programming

Quality Control in Manufacturing

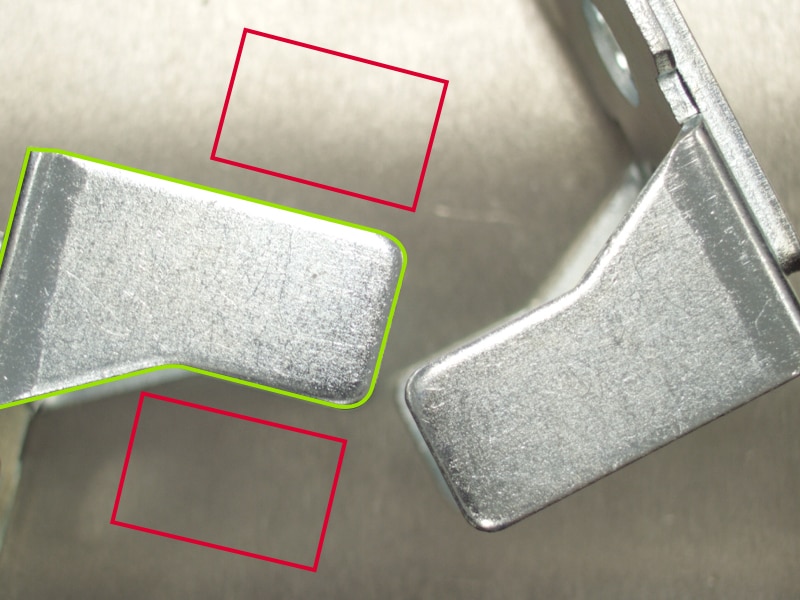

Quality control is one of the most common machine vision applications. These systems are excellent at detecting surface defects, verifying assembly, checking dimensions, confirming correct labels, and tracking products through production. Manufacturers reduce waste and rework costs by identifying issues early on.

Machine Vision in Sorting and Packaging

Vision systems quickly sort products based on visual characteristics while verifying package contents and inspecting packaging quality. This technology is especially valuable in the food and pharmaceutical industries where safety and proper packaging are critical.

Use of Machine Vision in Automotive and Electronics

In automotive manufacturing, vision systems check component assembly, inspect paint quality, and verify part placement. Electronics manufacturers use machine vision to place tiny components, check soldering quality, and verify circuit boards.

Medical Applications of Machine Vision

In the production of pharmaceuticals, medical devices, and packaging, machine vision guarantees accuracy and conformance. It ensures quality and safety by identifying flaws in surgical instruments and implants, confirming the integrity and labeling of pills, and checking packaging for correct barcodes, sealing, and expiration dates.

Discover more about this product.

Click here to book your demo.

Benefits of Machine Vision Programming for Businesses

Cost Savings and Increased Productivity

For management, ROI is always an important consideration. While implementing machine vision requires an upfront investment, the long-term savings are substantial. Automated inspection reduces labor costs, minimizes waste from defects, and prevents costly recalls. Production increases as inspection speeds surpass manual capabilities.

Improved Product Quality and Consistency

Machine vision is important in quality control, as each item is inspected with the same high standards, delivering consistent quality across the entire production process.

Real-Time Data and Analytics for Decision Making

Machine vision constantly gathers insights about what's happening on your production line. When a certain type of defect starts showing up more often, the system notices the pattern before it becomes a major problem. This gives managers the information they need to fix issues early rather than discovering problems after it's too late.

Enhanced Workplace Safety Through Automation

Some inspection jobs put people in harm's way - near extreme temperatures, hazardous chemicals, or dangerous machinery. Machine vision benefits workplaces by taking humans out of these risky situations by handling the inspection work.

KEYENCE Machine Vision Products and Solutions

Overview of KEYENCE Machine Vision Solutions

KEYENCE provides machine vision solutions for various industrial applications, from basic sensors to advanced inspection systems. All offer user-friendly interfaces for easy use and quick implementation.

KEYENCE Vision Sensors and Systems

The VS Series leverages AI and optical zoom for quick, precise inspections. The CV-X Series enables high-speed defect detection across industries, while the XG-X Series offers customizable programming and supports Line Scan and 3D cameras for advanced applications.

The VJ Series enhances PC-based vision with dynamic lighting and seamless software integration. The 3D Vision Series provides ultra-precise 2D/3D inspections, while the 3D VGR Series enables automated object detection and robot path planning.

The Line Scan Series captures high-speed images for detecting fine defects, and the 2D VGR Series optimizes pick-and-place robotics with easy calibration.

The Role of Deep Learning in KEYENCE Vision Technology

Deep learning enables AI-driven inspection, adaptive pattern recognition, and accurate defect detection. It also improves automation, shortens setup time, and boosts accuracy in applications like 3D vision and VGR.

Curious about our pricing?

Click here to find out more.

How to Get Started with Machine Vision Programming

Understanding the Technical Requirements

Before implementation, assess your specific needs, including production line speed, object characteristics, environmental conditions, and integration requirements with existing systems.

Selecting the Right Machine Vision System for Your Needs

When choosing a system, consider resolution needs, processing speed, lighting conditions, software capabilities, integration options, and possibilities for future expansion.

Key Steps in Implementing Machine Vision Programming

Defining needs, selecting equipment, optimizing lighting, developing programs, integrating systems, training staff, and establishing monitoring are all necessary steps in successful implementation.

Training and Resources for Machine Vision Programming

Invest in proper training for your staff. KEYENCE offers training programs from basic operation to advanced programming.

Contact us to get started today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Is AI Used in Machine Vision?

Yes, AI improves image analysis, pattern recognition, and defect detection, which in turn improves machine vision. In applications such as pharmaceutical quality control and medical device inspection, it makes decision-making more automated, flexible, and accurate.

Can Machine Vision Programming Be Integrated With Other Industrial Systems Like ERP or MES?

Yes, most advanced vision systems integrate with business systems like Enterprise Resource Planning (ERPs), allowing for comprehensive quality management and production monitoring.

How Do Machine Vision Systems Improve Data Security in Industrial Automation?

Vision systems provide objective, tamper-resistant documentation of production processes, creating verifiable records that satisfy regulatory requirements and customer audits.

What Industries Are Adopting Machine Vision Programming the Most?

Manufacturing leads in adoption, particularly automotive, electronics, pharmaceuticals, and food processing. However, logistics, agriculture, healthcare, and retail are increasingly implementing this technology.

Can Machine Vision Programming Be Applied to Non-manufacturing Sectors Like Healthcare or Logistics?

Yes, healthcare uses machine vision for diagnostic imaging and patient monitoring. Logistics operations use vision systems for package sorting and warehouse optimization.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics