Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

Machine Vision in Industry 4.0: Unlocking the Potential of Smarter Factories

Factories need faster machines that can make decisions in real time. Industrial machine vision systems deliver that with the ability to see, evaluate, and act automatically. In Industry 4.0 environments, these features are built in and help turn production lines into smart systems that detect issues early and adapt to changes.

The Core Technology Behind Machine Vision

How Machine Vision Works

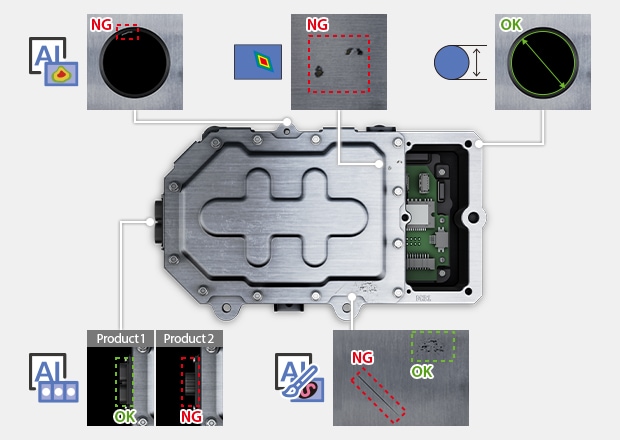

Machine vision captures images of products as they move through production and evaluates them based on preconfigured logic. Cameras capture the image, software analyzes it, and the system makes a judgment call on whether the item passes, fails, or is flagged. That product is then pushed to a control system, a reject pile, or logged for traceability.

Components of Machine Vision

A machine vision system includes five core elements: lighting, lens, image sensors, processing unit, and software. Lighting reveals key product features, and the lens focuses on the image. The sensor, typically CMOS, converts that image to digital data. Then, the processing unit, often a smart camera or vision controller, runs the inspection tools. KEYENCE systems include built-in tools for presence checks and defect detection without needing additional software.

Integration with Factory Automation Systems

KEYENCE vision systems like the VS Series can integrate with automation infrastructures through standard protocols like Ethernet/IP and Profinet. These systems can be triggered by sensors or machine timing, returning inspection results in real time, which can be used to stop a process or log inspection outcomes for analysis and traceability.

Get detailed information on our products by downloading our catalog.

View Catalog

Key Benefits of Machines in Industry 4.0

Enhanced Quality Control

Industrial machine vision systems can inspect every product instead of just sampling. It identifies missing components, label errors, and surface flaws that maintain accuracy regardless of shift changes or repetition, unlike human inspections.

Increased Efficiency and Speed

Automated inspections mean that manufacturers can reduce delays caused by manual checks. Vision systems free up operators and allow production to continue at full speed. Multi-camera setups lessen the need for multiple stations, and high-speed image processing means inspections happen without slow production.

Improved Data Collection and Analysis

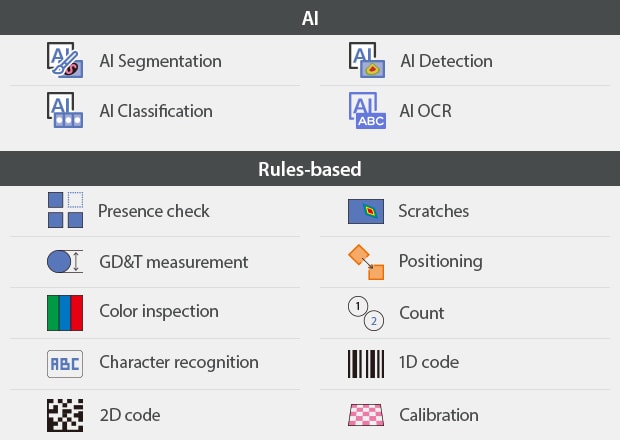

Each inspection result can be stored with a timestamped image and part ID. This data is valuable for traceability and line optimization. Instead of waiting for a defect to appear further in production, manufacturers can address it with full visibility into inspection trends.

-

1Drag & drop to link data

-

2Use auto-fill to generate detailed tables

-

3Create various charts with just a few clicks

Cost Reduction

Vision systems help reduce rework and scrap by catching problems early. They also lower labor costs by minimizing the need for manual inspectors, stabilizing the inspection process, and reducing maintenance costs.

We’re here to provide you with more details.

Reach out today!

The Impact of Machine Vision on the Future of Manufacturing

Driving Industry 4.0 Transformation

Machine vision in manufacturing helps collect visual data and feeds it into analytics platforms, allowing manufacturers to respond faster, make better decisions, and spot problems before they cause delays.

Enhancing Worker Safety

Through automating high-risk or repetitive inspections, industrial machine vision improves safety on the production floor. These systems verify correct part placement or detect issues that might lead to tool damage, all without putting operators in harm’s way.

Future Trends in Machine Vision

The setup process of vision inspection systems is getting faster with built-in AI tools that reduce trial and error. Smart tuning features make it easier to adapt to new products without reprogramming. As machine vision and applications expand, so does accessibility, and teams can now deploy inspection solutions without needing deep technical knowledge.

Getting Started with KEYENCE Machine Vision

Innovative Features of KEYENCE Vision Systems

KEYENCE systems combine precision hardware with user-friendly software, including features like auto-focus, adjustable lighting, and multi-camera support. Controllers run inspections without needing to rely on external PCs. These systems are also built to handle lighting and surface finish variations without compromising inspection accuracy.

How to Implement Machine Vision in Your Factory

Deploying an industrial machine vision system starts with defining a specific inspection requirement. This could be verifying the presence or position of a component or measuring part dimensions within tight tolerances. From there, production conditions have to be assessed to determine which system configuration will provide the most stable results.

Once these parameters are established, the next step is selecting the appropriate components and confirming their performance on actual product samples. KEYENCE provides direct technical support throughout this process, including proof-of-concept testing and integration guidance. Vision systems can then be configured through intuitive software interfaces and deployed without extensive custom coding or third-party development.

Installation can often take place within a standard maintenance window, and in many cases, users are able to bring a station online in less than a week, with full inspection capability and logging in place from day one.

Contact KEYENCE for a Consultation

If you’re in the market to evaluate industrial machine vision systems for your production lines, contact KEYENCE today to schedule a demo of how our products can improve your processes.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Types of Industries Can Benefit Most From Machine Vision?

Machine vision in industry is used in electronics, automotive, pharmaceuticals, food, and packaging, anywhere precision and speed are needed.

How Does KEYENCE Ensure the Accuracy of Machine Vision Systems?

Through stable lighting, high-resolution cameras, and refined software tools. KEYENCE systems maintain accuracy across changes in part color, shape, or orientation. AI tools improve reliability when working with complex characters or printed codes.

Can Machine Vision Systems Adapt to Changes in the Production Line or Manufacturing Environment?

Yes. Systems are built to handle vibration, lighting changes, and part variation with minimal adjustment.

Is Training Required to Operate KEYENCE Machine Vision Systems?

Basic operation requires little training as the interface is intuitive. For more advanced adjustments, KEYENCE provides onboarding support, application documentation, and direct help from local engineers.

Can Machine Vision Systems Help With Predictive Maintenance?

They can detect early visual signs of wear or misalignment, giving teams time to respond before failures occur.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics