Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

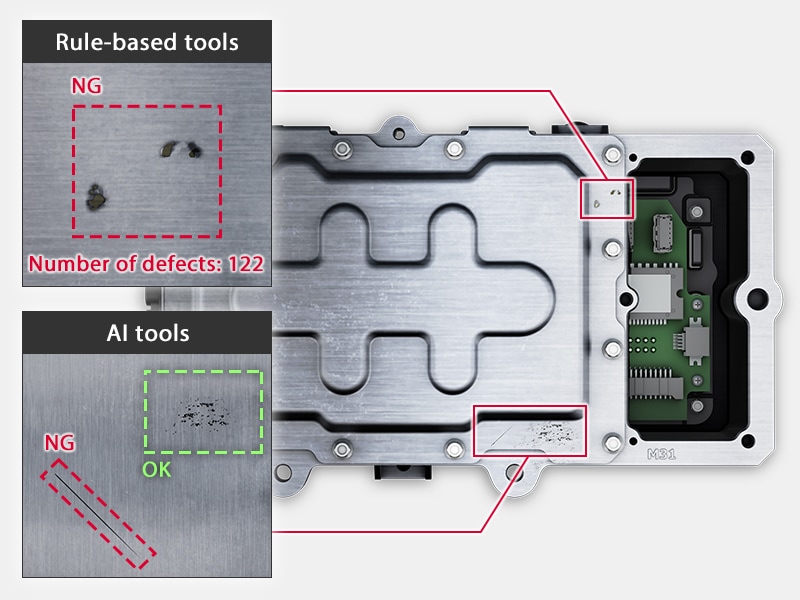

Rule-Based vs. AI-Powered Machine Vision Tools: Which is Right for Your Application?

Rule-based and AI-powered machine vision systems represent entirely different approaches to processing and interpreting visual data. Each of these systems can be tailored to meet specific operational and environmental requirements.

Machine vision systems are used in modern industrial automation. These systems enable rapid and accurate visual data processing, aiding in processes like quality assurance and assembly verification, and rely on rule-based or AI-powered vision.

Rule-based systems depend on predefined algorithms and logic to execute their tasks. AI-powered systems use machine learning to adapt to their tasks and environments dynamically.

Choosing the right approach has to be based on more than personal preference. It’s a decision that needs to be made based on operational efficiency and scalability. This article will help you understand rule-based vs AI machine vision and decide which is best for your needs.

What is Rule-Based Machine Vision?

Rule-based machine vision is the more traditional approach to visual data processing. It relies entirely on defined algorithms and logic to interpret and analyze images. They were designed by programming a series of step-by-step instructions, typically in the form of ‘if-then’ statements. This helps identify, measure, and classify objects. For example, a rule-based machine system might measure the distance between two edges or identify manufacturing defects based on grayscale values and pixel contrasts.

Engineers find that this particular method excels in environments where the outcomes are consistent and predictable. Tasks like varying dimensions or guiding robotic operations are where rule-based systems shine. However, since they rely on rigid logic, they are limited in their ability to adapt.

AI Machine Vision: Deep Learning and Edge Learning Systems

AI-powered machine vision has revolutionized visual data processing, as they are more flexible. Unlike rule-based tools, artificial intelligence machine vision tools learn patterns from large datasets. It uses machine learning to adapt to complex and dynamic environments.

Deep Learning in Machine Vision

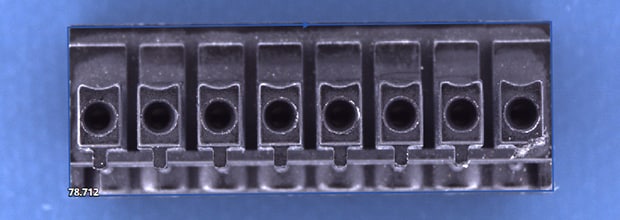

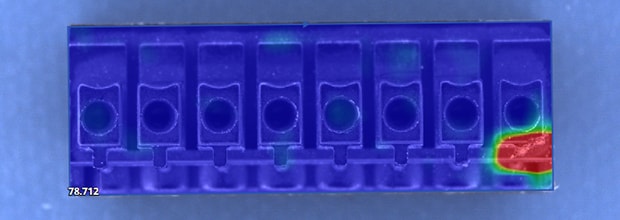

Deep learning relies on neural networks to analyze features such as edges, textures, and shapes. These systems detect subtle defects and classify objects in a variety of challenging conditions like inconsistent lighting or material reflectivity.

Edge Learning: A Lightweight AI Solution

Edge learning offers a faster and less resource-intensive alternative. These systems come pre-trained for standard applications and quickly adapt to new scenarios with minimal training. They also require minimal setup and are ideal for repetitive defect detection or classification.

Advantages of AI Machine Vision

AI machine vision systems go beyond the scope of rule-based systems with their variability and ability to solve complex problems. Unlike many AI-powered solutions that need hundreds of images and extended data training, the VS Series smart camera leverages edge learning to achieve remarkable results in just minutes. With an average of 20 images, it quickly learns to identify what a "good" product looks like and flags any deviations. This approach makes the tool adaptable and enhances efficiency.

Comparing Rule-Based vs AI Machine Vision

Choosing between rule-based and AI-powered machine vision approaches depends on the task at hand. Rule-based systems excel in stable and predictable scenarios. Providing high-speed precision for repeatable tasks. However, their rigidity requires manual updating for even the smallest of changes.

On the other hand, AI-powered tools adapt dynamically to a situation. They can handle complex tasks with ease. Deep learning helps analyze patterns, while edge learning enables rapid deployment with very minimal training.

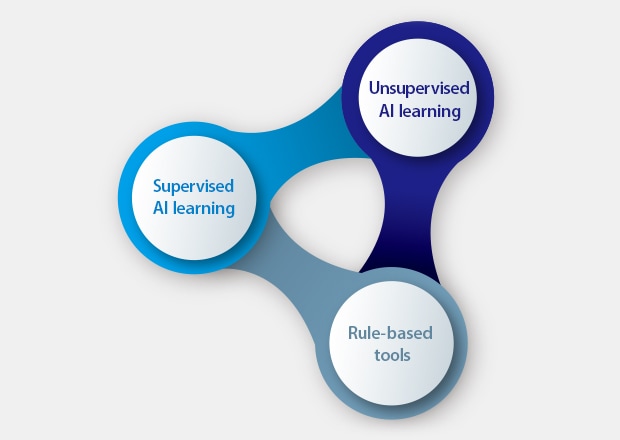

The key difference lies in their adaptability. For many applications, a hybrid approach combines the precision of rule-based logic with the flexibility of AI to address diverse challenges. An example of this is a production line that might use rule-based logic for high-speed inspections and an AI vision system for analyzing irregularities.

Get detailed information on our products by downloading our catalog.

View Catalog

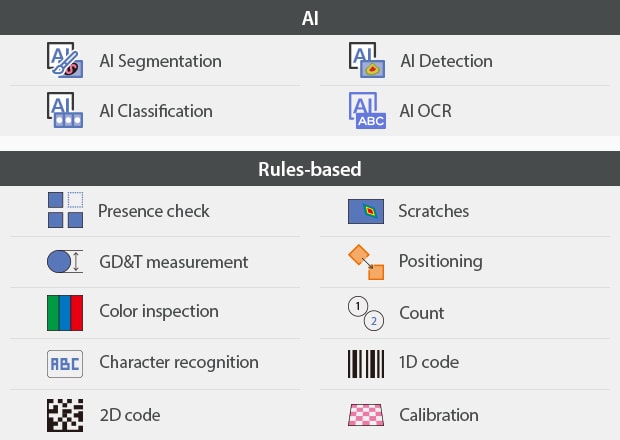

Why Choose a System That Combines Rule-Based and Artificial Intelligence-Based Machine Vision Tools

Visual data processing requires a careful balance between complexity and adaptability. Rule-based systems deliver precise results for specific tasks, while AI-powered tools excel in dynamic, ever-changing scenarios. When combined within a single system, these two approaches offer an optimal blend of accuracy and flexibility, making it easier to manage a wide range of inspection challenges.

Integrating rule-based and AI-powered vision tools results in a more robust approach to visual data processing. The VS Series is equipped with a user-friendly interface for the straightforward configuration of rule-based inspections alongside advanced AI algorithms capable of adapting and learning from varied scenarios. This powerful integration enables the system to address challenges, such as character recognition and defect detection, with outstanding precision.

Learn More About AI Machine Vision Technology with KEYENCE

The KEYENCE VS Series Vision System exemplifies the precision of rule-based systems and the adaptability of AI. To start, the VS Series contains ZoomTrax Technology. With the inclusion of a series of mechanical zoom lenses, the VS Series can deliver precise optical zoom with no loss in resolution. This design removes the need to change lenses manually for different tasks. It also supports a variety of inspections while keeping image quality high.

The VS Series also has Edge AI capabilities that can perform with minimal training data. It can learn from a minimum of two to five images, which means faster deployment. It features an intuitive Vision Dashboard, which provides real-time visualization, simplifying troubleshooting. The Dashboard is also accessible and easy to use for operators of varying experience levels.

Whether inspecting high-speed production lines or identifying intricate defects, KEYENCE machine vision systems deliver flexibility and efficiency. These systems combine AI-powered adaptability with rule-based reliability to help improve operations, enabling quick adjustments to minimize downtime.

Interested? Explore KEYENCE machine vision systems

to learn more about how they can transform your operations. Discover the advanced capabilities of the AI vision system offered by the VS Series. Contact KEYENCE today to take the next step in optimizing your industrial processes!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics