Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics

How Food Vision Inspection Systems Optimize Packaging for Better Product Quality and Compliance

The food and pack industry uses vision systems to ensure quality standards are being met. These inspections can include character and code reading, defect detection, and measurement. Food vision inspection systems can consist of smart cameras that run these inspections and output the data for tracking and traceability purposes.

What Are Food Vision Inspection Systems?

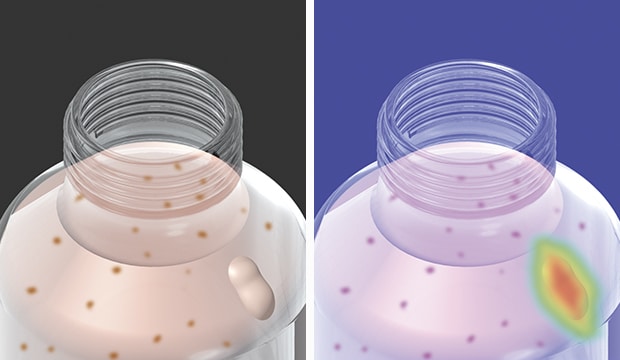

Inspection for condiment spillage

Food vision inspection systems use advanced cameras, sensors, and software to monitor and evaluate products during packaging. These systems scan each unit in real time with precision, capturing subtle visual details that the human eye might miss. They identify issues like misaligned labels, incorrect fill levels, damaged containers, and missing or tampered seals. When integrated into the production line, these vision systems automate quality control while reducing inspection time and overhead.

In practice, they combine high-resolution imaging with machine learning algorithms or rule-based pattern detection, enabling manufacturers to spot defects quickly, maintain uniform product quality, and comply with labeling and safety regulations.

We’re here to provide you with more details.

Reach out today!

How Vision Technology Enhances Food Packaging Quality

Vision inspection systems handle safety and compliance issues in food manufacturing, running multiple checks per unit without slowing production.

At the seal, systems can detect leaks, gaps, or wrinkles, which might otherwise allow contaminants or spoilage to occur. In container checks, geometry and structural integrity are evaluated to prevent defective items, such as dented cans or warped trays, from reaching shelves. They also measure fill levels to identify underfilled or overfilled containers, which can lead to waste or compliance violations.

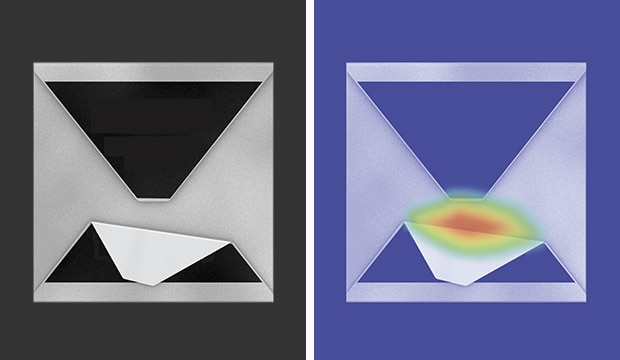

Inspection for individual package defects

Label quality and placement are scanned using optical character recognition (OCR) tools that read printed information, such as expiration dates, nutritional data, or allergen warnings. Misprints, incorrect batch codes, and missing fields are flagged instantly. This real-time feedback loop allows production teams to adjust settings before minor defects escalate into product-wide issues.

At the secondary packaging level, vision systems verify assembled cases, tamper-evident packaging, and barcode readability. They confirm that every tray, box, or shrink-wrapped unit is correctly labeled and sealed before distribution.

Discover more about this product.

Click here to book your demo.

Challenges of Manual Inspections

Manual inspections have limits. Human inspectors are prone to fatigue, inconsistent judgment, and missed details, especially in high-speed or repetitive environments. Visual fatigue alone can cause otherwise trained workers to overlook packaging misalignments or subtle seal defects. Even with experience, people can struggle to maintain accuracy when inspecting hundreds or thousands of units per shift.

Moreover, manual checks don’t scale easily. Increasing throughput requires more inspectors, training, and supervision. For fast-moving production lines, that means higher cost and increased error risk. In contrast, machine vision systems operate 24/7, don’t require breaks, and log inspection data automatically.

They also reduce subjectivity. An automated system uses the same evaluation criteria from the first container to the thousandth. Achieving consistency is challenging even with the most diligent human workforce.

Key Features of Food Vision Inspection Systems

The strength of vision inspection lies in its layered capabilities. At the hardware level, these systems include high-speed cameras, multi-angle lighting setups, and precision sensors that capture surface and dimensional data. On the software side, machine learning algorithms compare each product against a model of acceptable tolerances.

Modern setups feature spectral imaging that detects contaminants invisible to the naked eye, as well as vacuum inspection tools to evaluate pressure seals on products like soups, sauces, or vacuum-packed produce. Systems verify the presence of safety seals, check barcode accuracy, and detect mismatched lids or tamper indicators.

They’re also built to fit the environment. Most systems are installed directly onto conveyors and align with existing packaging formats. When they find a fault, they trigger reject mechanisms on the spot. Many models can also connect with equipment upstream and downstream to trace where issues originate, whether it’s filling, labeling, or capping.

For production teams, the interface matters just as much as the tech. Operators don’t need coding experience to access inspection stats, failure logs, or batch performance.

See the benefits firsthand by signing up for a free trial now.

Free Trial

Compliance and Quality Assurance Benefits

Vision systems contribute directly to product safety and regulatory compliance. They verify that each container includes the correct product information, label data, and safety features and scan for missing allergen disclosures, misaligned labels, unreadable expiration dates, and faulty safety seals before any unit leaves the line. Every scan creates a digital paper trail to support audits, recall tracebacks, and internal quality control reviews. If an issue arises after distribution, the manufacturer can isolate affected batches quickly rather than pulling every product.

These systems also reduce the likelihood of expired or improperly coded items entering the supply chain. Automated date and lot code verification helps maintain clear records for retailers and customers while protecting the brand from mislabeling claims.

Future Trends in Food Vision Inspection Systems

New machine vision systems integrate deep learning models that improve over time, learning from visual data to distinguish between acceptable variation and defects. For example, packaging environments that handle baked goods, produce, or other products that naturally vary in shape or texture benefit immensely from this process.

Another area that is seeing rapid development is predictive maintenance. Some systems monitor inspection device performance and flag early signs of wear or drift before a fault impacts throughput. This reduces unplanned downtime and helps manufacturers schedule maintenance at the least disruptive time.

Modular designs are expanding access as vision tools can now be implemented in smaller facilities or retrofitted into older production lines. Some mobile-friendly systems even offer camera-based inspections for smaller packaging operations, extending visual quality assurance (QA) to areas where automation was once cost-prohibitive.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Types of Defects Can Food Vision Inspection Systems Detect?

These systems catch label misprints, skewed placement, incorrect barcodes, seal defects, underfills, container dents, and foreign object contamination.

How Does Food Vision Technology Improve Production Efficiency?

By replacing manual checks with real-time scanning, vision systems reduce errors and prevent bottlenecks. They also enable faster production speeds without compromising accuracy.

Can These Systems Be Integrated With Existing Packaging Lines?

Yes, most systems are modular and adaptable. They can be added to conveyors, sealers, labelers, or rejection points without requiring complete line redesigns.

What Role Does AI Play in Food Inspection Systems?

AI supports pattern recognition and continuous learning, allowing the system to improve over time, identify subtle defects, and adapt to natural variations in products.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics