Static Control

- Multi-Sensor Ionizer SJ-F700 series

- High-Accuracy High-Speed Sensing Ionizer SJ-Q series

- Energy-Saving High-Speed Sensing Ionizer SJ-E series

- Air-Free High Speed Sensing Ionizer SJ-H series

- Compact Nozzle Static Eliminator SJ-LM series

- Ultra-durable, High-power Static Elimination Gun SJ-LG series

- Compact Fan Static Eliminator SJ-LF series

- High-Performance Micro Static Eliminators SJ-M series

- High-Accuracy Inline Electrostatic Sensor SK series

- Electrostatic Sensor SK-H series

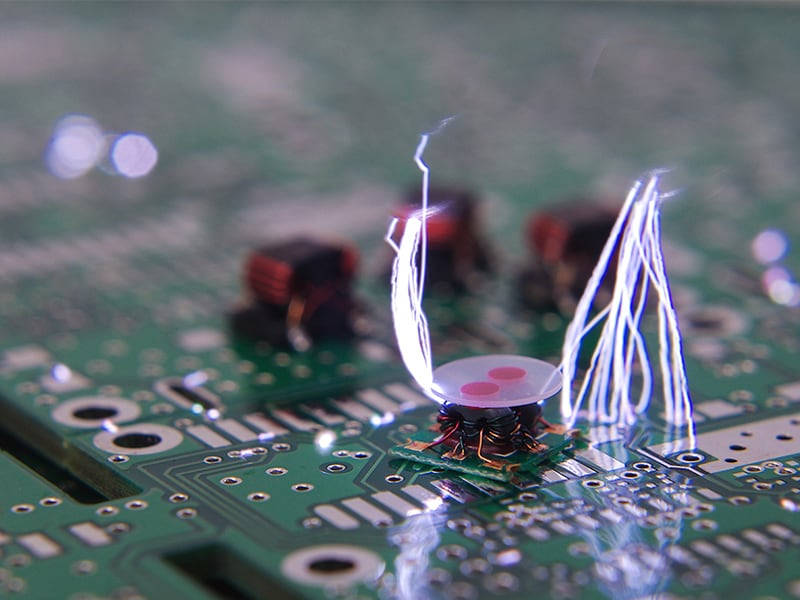

What is Electrostatic Breakdown?

Key Takeaways

- Electrostatic breakdown is insulation failure when voltage exceeds a material's limit, causing sudden conduction.

- Many metal-oxide semiconductors fail at just 80 to 100 volts, far below human-shock thresholds.

- Thinner oxides, higher circuit density, automation, and low humidity increase ESD risk.

- Continuous ESD control—grounding, conductive surfaces, ionizers, humidity, dissipative packaging—prevents damage.

Electrostatic breakdown occurs when the voltage across an insulating material rises beyond its limit, causing the material to suddenly conduct electricity. In manufacturing and electronics, this surge can destroy delicate components built on thin oxide layers. The smaller and more advanced devices become, the more sensitive they are to voltage stress. Understanding how electrostatic breakdown forms, why it continues to grow as a concern, and how modern electrostatic discharge (ESD) solutions prevent damage is key to maintaining stable, high-yield production environments.

How Electrostatic Breakdown Affects Electronics

Electrostatic breakdown is, essentially, the point where insulation fails. In an integrated circuit, each transistor and pathway is separated by a thin insulating film. When static charge builds, the electric field surpasses that limit and the barrier collapses. Current then flows through the film, damaging internal structures.

Humans feel a shock around 3,000 volts, but many metal-oxide semiconductors fail at just 80 to 100 volts. Thin-film resistors, GMR heads, and LCD panels tolerate slightly more, but the margin is narrow. That contrast between perception and vulnerability makes electrostatic damage prevention a central challenge in electronics.

| Type | Tolerable Voltage |

|---|---|

|

Type

GMR head

|

Tolerable Voltage

5 V or less

|

|

Type

MR head

|

Tolerable Voltage

10 V or less

|

|

Type

LCD industry

|

Tolerable Voltage

100 V or less

|

|

Type

Power MOSFETS

|

Tolerable Voltage

100 to 300 V

|

|

Type

VLSI

|

Tolerable Voltage

1,000 to 3,000 V

|

|

Type

Linear MOS

|

Tolerable Voltage

800 to 4,000 V

|

|

Type

Bipolar

|

Tolerable Voltage

2,000 to 8,000 V

|

|

Type

Thin-film resistance

|

Tolerable Voltage

1,000 to 5,000 V

|

We’re here to provide you with more details.

Reach out today!

Why is Electrostatic Breakdown a Growing Concern?

Modern components have thinner oxide layers and denser circuitry. While this raises performance, it also lowers voltage tolerance as circuits that once survived thousands of volts now fail at a few dozen. In advanced manufacturing, these limits make static discharge one of the most common hidden risks during handling or automated assembly.

ESD protection in manufacturing is harder as automation and high-speed transport increase friction between materials. Low humidity raises surface potential, allowing stray fields to form on housings and plastics. As density rises, the same field that was harmless decades ago can now pass through multiple layers of microcircuitry. Effective electrostatic breakdown prevention now requires continuous control rather than occasional checks.

Protecting Your Devices from Electrostatic Breakdown

A sound ESD control program begins with grounding and conductive work surfaces. Operators and tools share a common potential, so the charge dissipates safely. Conductive flooring and wrist straps help prevent buildup, while antistatic mats and dissipative tools reduce charge generation.

Humidity control supports electrostatic damage prevention by reducing charge on insulators. Air ionizers add another layer by releasing balanced ions that neutralize stray charges in the workspace. Dissipative packaging and containers protect parts between stations, preventing electrostatic discharge during transport.

The goal is a stable electrical environment where charge never accumulates faster than it can dissipate. When all surfaces and operators remain at the same potential, the risk of breakdown drops sharply.

Avoiding Equipment Failures and Risks with Electrostatic Breakdown Prevention

When electrostatic levels stay balanced, components go on to operate as designed and production stays on schedule. Ionization systems keep that risk in check across assembly lines and cleanrooms alike. With steady electrostatic damage prevention and control, measurements stay consistent, and parts reach the next stage without rework.

Find out how to protect your equipment from electrostatic damage.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Which Electronic Components are Most Vulnerable to Electrostatic Breakdown?

Thin-film devices such as GMR heads, MOSFETs, and LCD assemblies are highly sensitive. Typical breakdown voltages range from below 10 V to around 100 V.

What is the Tolerable Voltage for Different Devices?

While some power components handle several thousand volts, integrated circuits and metal-oxide semiconductors often fail below 100 V. As devices shrink, tolerances continue to fall, making precise ESD protection essential in manufacturing.

Why is Electrostatic Breakdown a Growing Concern in the Electronics Industry?

Smaller components and faster lines leave less room for voltage variation. In dry air, plastic housings and film surfaces hold charge longer.

We’re here to provide you with more details.

Reach out today!