Vision Systems

- Vision System with Built-in AI VS series

- Intuitive Vision System CV-X series

- Customizable Vision System XG-X series

- GigE camera and lighting for PC-based machine vision VJ series

- Inline 3D Inspection 3D Vision series

- 3D Vision-Guided Robotics 3D VGR series

- Line Scan Technology Line Scan series

- 2D Vision-Guided Robotics 2D VGR series

- LED Lighting CA-D series

- Lenses (for Machine Vision) CA-L series

- Machine Vision System Database VisionDatabase series

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

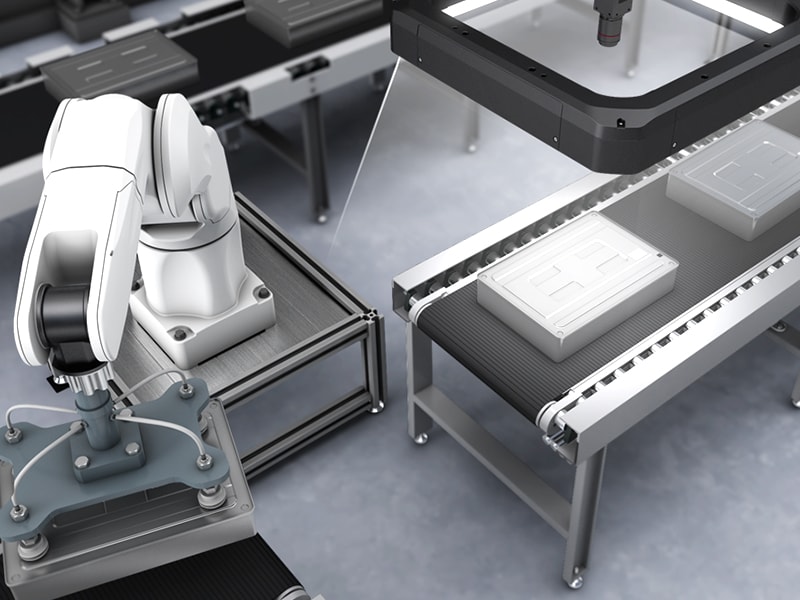

- Vision-Guided Robotics

Transforming Warehouses: The Power of Machine Vision in Automated Logistics

Key Takeaways

- Machine vision automates real‑time inspection to raise throughput while keeping quality consistent.

- Start implementations on high‑speed, repetitive bottlenecks to realize fastest ROI.

- Integrate vision with PLCs, robots, and conveyors for immediate control actions and process feedback.

- Modern systems handle multi‑product lines via software updates, cutting rework, scrap, and labor costs.

For most manufacturers, speed and precision determine whether a line keeps moving or falls behind. When operators pause to double-check a mark or rework a defect, that slowdown spreads fast across production. Automated vision inspection equipment takes over those checks, using cameras and lighting to verify each product in real time. In both logistics and manufacturing, machine vision systems have become a direct way to improve throughput while holding quality steady.

Overview of Modern Manufacturing Challenges in Throughput and Quality

Every production line today runs under pressure to move faster while keeping output consistent. Smaller parts, tighter tolerances, and mixed product runs leave little room for human error. Manual inspection often slows the process, and fatigue only increases the chance of a missed defect or an uneven pass.

Automated vision inspection systems close that gap. They capture and evaluate images in real time, maintaining accuracy even at full line speed. Paired with industrial automation equipment, these systems make inspection part of the process, turning quality checks into continuous feedback that keeps production steady.

We’re here to provide you with more details.

Reach out today!

Understanding Automated Vision Inspection Systems

In practice, automated vision inspection equipment works like a set of trained eyes running at machine speed; as each product moves along the line, cameras grab images and the software evaluates shape, position, and surface detail in real time. The system then logs the results automatically, creating inspection data that operators can trace or review whenever it’s needed.

Modern machine vision systems are flexible enough to handle nearly any task, like checking dimensions, confirming assembly, reading barcodes, or spotting surface flaws. Whether metal, plastic, or film, these systems react faster than the eye can follow. That combination of optical precision and fast processing keeps inspection consistent across every product, every shift.

Key Benefits of Automated Vision Inspection Systems

Faster Throughput and Improved Efficiency

Automation removes manual checks. Automated vision inspection systems analyze every unit in real time, keeping pace with production. This nonstop operation increases throughput and accuracy while integrated data instantly directs sorters, robots, and conveyors.

Enhanced Quality Control and Consistency

Automated vision inspection equipment keeps inspection standards consistent across shifts and high-volume runs. Systems don’t tire or lose focus, maintaining accuracy even during long operations.

Advanced lighting and optics detect scratches, contaminants, fill variations, and label errors. In electronics, automotive, and packaging, that consistency protects product reliability and line performance.

Operational Cost Savings and ROI Benefits

Reducing human inspection time lets skilled operators handle higher-value work. Automated vision inspection systems also cut waste by finding defects early and preventing rework. Fewer scrap and stoppages reduce operating costs.

Inspection trend data supports predictive maintenance, helping teams prevent downtime and sustain long-term performance gains.

Discover more about this product.

Click here to book your demo.

Implementing Machine Vision Systems in Manufacturing

In most facilities, implementation starts with the areas that slow output the most. High-speed, repetitive inspections usually show the fastest return, so they’re a smart first step. From there, automated vision inspection equipment can tie into conveyors, robotic cells, or stand-alone stations with minimal change to the line. Training gives operators confidence with setup, recipe control, and reading inspection data.

Day-to-day upkeep, lens cleaning, quick checks, and the occasional software tune-up is simple. Once installed, these systems run steadily and can switch between products or materials through software updates instead of hardware changes.

Integrating Vision Systems with Industrial Automation Equipment

In most plants, machine vision systems perform best when they’re part of a larger, connected network. Understanding the differences between human vision vs. machine vision in industrial inspection helps clarify why this integration matters. Machine vision systems talk directly with PLCs, robots, and motion controllers, feeding back the kind of data operators can act on right away. Sometimes that means ejecting a part the moment a defect appears; other times it’s a small process tweak that keeps the run stable.

This live connection also gives engineers a clearer picture of how efficiently the line is running. When inspection data flows into plant-monitoring software, it points to exactly where throughput can improve. That steady exchange between vision and automation keeps production moving forward without adding layers of complexity.

Curious about our pricing?

Click here to find out more.

Example Industry Applications

Automotive: Inline Quality Control at Full Speed

Automated vision inspection systems verify parts as they move through assembly, checking welds, dimensions, and surface finishes in real time. This minimizes rework and keeps production moving while maintaining high accuracy across stations.

Electronics: High-Precision Inspection for Complex Assemblies

In electronics manufacturing, machine vision systems measure solder joints, confirm markings, and check component orientation at microscopic levels. They also provide fast feedback that helps fine-tune processes, reducing variation and improving first-pass yield.

Consumer Goods and Packaging

For packaging and labeling, automated inspection checks codes, lot marks, and label placement and with integrated lighting, captures clear images on reflective or transparent surfaces, maintaining accuracy at high line speeds and improving throughput across varied packaging materials.

Improve Throughput with KEYENCE’s Machine Vision Systems

KEYENCE machine vision systems combine precision imaging, high-speed processing, and flexible integration to elevate productivity across industries. Each unit communicates directly with automation controllers and robotics, linking inspection outcomes to real-time control actions.

The VS Series and CV-X platforms deliver fast, stable inspection with adaptability for changing product types. Designed for continuous use in demanding environments, these systems help manufacturers improve throughput, maintain consistent quality, and sustain long-term operational efficiency.

By uniting inspection, measurement, and control within one platform, KEYENCE machine vision systems make reliable, high-speed production achievable across every process.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Do Automated Vision Inspection Systems Improve Throughput on a Production Line?

They operate in real time, analyzing each product at full line speed. Continuous inspection removes manual bottlenecks, reducing downtime and maintaining steady output.

Is Automated Vision Inspection Equipment Difficult to Integrate Into Existing Production Lines?

No. Most systems use standard communication protocols to connect with PLCs, robots, and other automation equipment already in use.

What Are the ROI Benefits of Deploying Machine Vision Systems for Quality Control?

Manufacturers gain lower labor costs, fewer production stops, reduced scrap, and higher yields. These factors combine into a measurable, lasting ROI.

Can Automated Vision Inspection Systems Handle Multiple Product Types or Design Changes?

Yes. Product parameters can be updated through software without replacing hardware, making them suitable for high-mix manufacturing.

How Do Vision Inspection Systems Compare to Human Inspectors in Accuracy and Consistency?

They maintain constant accuracy regardless of shift length or operator variation, capturing details that manual inspection may overlook.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Industries

- Aerospace

- Automation Equipment/Machine Building

- Automotive

- Commodities

- Defense

- Electric Vehicles

- Electronic Device

- Fabric/Textile

- Food/Beverage Packaging

- Logistics

- Machine Tools

- Marine

- Medical Device Manufacturing

- Mining/Metals

- Paper Manufacturing

- Pharmaceuticals

- Printing

- Semiconductor/Manufacturing Electronics

- Solar

- Tobacco

- Vision-Guided Robotics