Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Coding Primary vs. Secondary Packaging: What You Need to Know

Packaging is one of the most visible yet ignored aspects of modern production. Most consumers don’t stop to consider the structure behind a blister pack or the label on a soda bottle. Beneath the branding is a series of necessary layers of information that keep supply chains moving and products compliant.

What Is Primary Packaging?

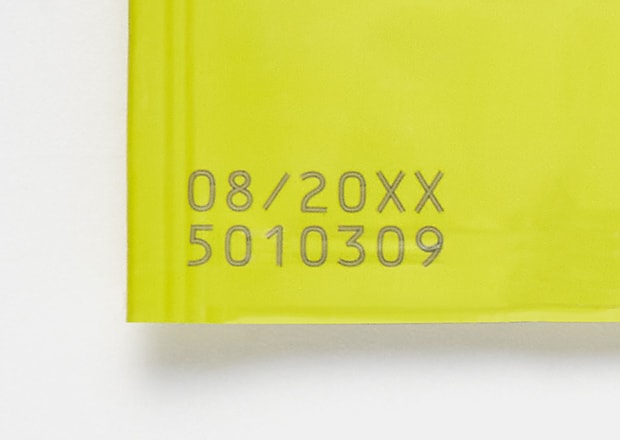

Primary packaging is the material that comes in direct contact with the product, whether that’s a bottle that holds a liquid or the cello pouch that keeps snacks fresh. In many industries, this is the layer that has the highest regulatory burden. It has to preserve the product and carry important data for traceability. Typically, this layer has fine text like expiration dates, lot numbers, and manufacturing codes, which have to be legible. Since it’s consumer-facing, these codes also need to blend into the packaging without compromising the appearance of the product.

We’re here to provide you with more details.

Reach out today!

What Is Secondary Packaging?

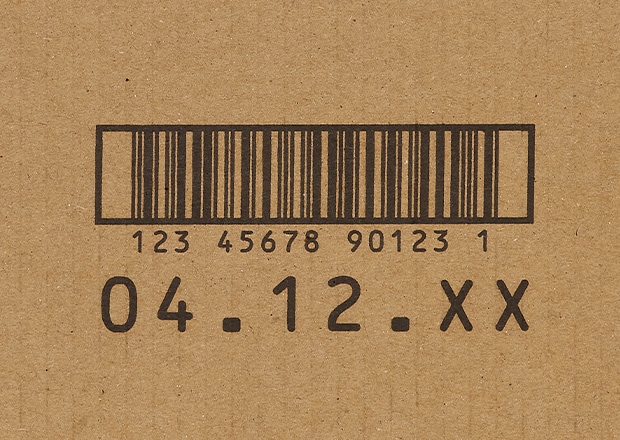

Secondary packaging contains one or more primary packages. Cartons, shrink wrap, chipboard trays, and boxes all qualify as secondary packaging. These packages consolidate multiple products for storage, handling, and transit, and most are rarely seen by customers unless purchased in bulk.

What matters most at this stage is traceability and throughput. Secondary packages often feature larger barcodes, shipping information, and inventory data. This is the layer that is scanned throughout warehouses and distribution centers to track where the package came from and where it is headed.

Where Tertiary Packaging Fits In

This layer is the outermost shell; think shrink-wrapped pallets or large shipping containers. These are typically built for durability and load handling, not visual appearance. Codes at this level prioritize readability and consistency. Pallet labeling, in particular, must withstand warehouse conditions and rough transport without losing its labels.

Tertiary packaging is often overlooked in printing conversations, but when skipped or mishandled, gaps in inventory access become apparent, and packaging no longer meets regulatory compliance.

Products for Primary Packaging Coding

KEYENCE offers a wide range of products for any packaging solutions, like the FP-1000 UV laser coder, the MK-G Series continuous inkjet printer, and the CC-1000 Series high-resolution case coder. While each of these printers can offer options across primary and secondary packaging layers, they are not all built for every surface.

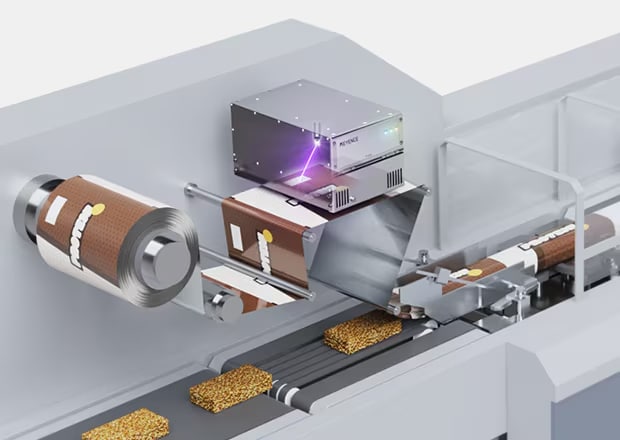

For primary packaging, the FP-1000 Series excels where a mark must be permanent and precise. It uses a UV wavelength to print hard-to-code substrates like plastic film, foil, or other fragile materials without leaving damage on the product or distorting the package. The FP-1000 Series is heatless and non-contact, and it doesn’t require ink or solvents, which makes it ideal for environments that are focused on cleanliness and low-maintenance machines.

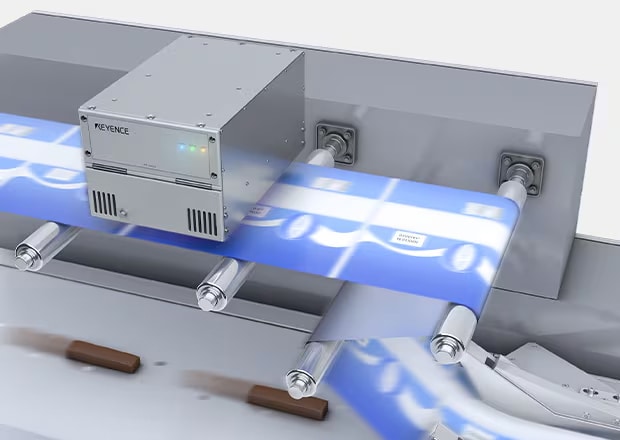

On the other hand, the MK-G Series CIJ printer supports high-speed, continuous production of primary items like bottles, cans, or pouches. The MK-G Series can print hardwearing alphanumeric and batch codes even on curved or flexible materials. It features a compact build that fits easily into tight production spaces and, with a wide range of ink formulations, the MK-G Series adapts to different surface types and production conditions.

Discover more about this product.

Click here to book your demo.

Comparison of KEYENCE Solutions for Primary and Secondary Packaging

Each printer fits into the packaging stack differently. The FP-1000 Series is best deployed on primary lines where ink-free, abrasion-resistant codes are required, especially for the medical, cosmetic, and food industries. As it operates without consumables, it’s perfect for facilities where uptime and cleanroom compatibility are a must.

The MK-G Series CIJ is built for both primary and light-duty secondary packaging. Its high-speed, high-contrast outputs make it suitable for flat and curved items, but can also be adapted for boxes and trays in slower secondary lines when needed. Its ink options include dye-based and pigment inks that are fast-drying for materials that are more resistant to standard printing.

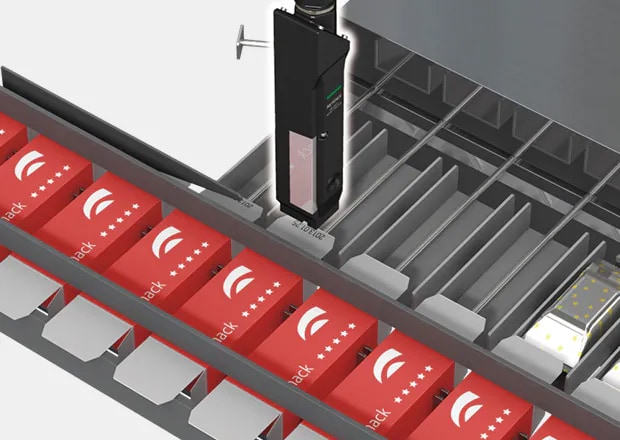

The CC-1000 Series, by contrast, is chiefly used for secondary packaging coding. This piezo-driven high-resolution inkjet printer delivers sharp text, barcodes, logos, and graphics on porous surfaces like corrugated boxes. It features a dual-head option and high DPI settings, which are excellent for warehouse-ready labeling. Because it is not designed to handle non-porous or glossy surfaces, it should not be used for primary packaging coding.

Curious about our pricing?

Click here to find out more.

Products for Secondary Packaging Coding

For boxes and trays, the CC-1000 Series is the go-to system. It can print large, scannable barcodes and crisp alphanumerics directly on corrugated cases. The system is also easy to adapt to existing production lines, keeping batch information and real-time variable data printing smooth.

The MK-G Series can serve in secondary roles when pigment-based inks are used, but should be limited to smaller batches or specialized cases. This is particularly useful in facilities that need flexibility across packaging types or are transitioning between different materials.

Materials and Surface Considerations

Surface texture, gloss, and porosity matter as much as speed and throughput. Glossy or non-porous materials require inks that dry quickly or marks that don’t require ink, like the FP-1000 Series.

Porous surfaces like cardboard absorb ink well, making them compatible with high-resolution case coders like the CC-1000 Series. The multi-sensing unit on the CC-1000 Series can predict changes in speed or when the line stops to ensure consistent prints, and also has a built-in inspection camera to ensure no parts are being shipped without the proper codes.

With KEYENCE, you can select the perfect coder for each layer of your packaging. From primary to tertiary, our systems ensure reliable, high-performance marking.

Ready to find the right solution for your packaging needs? Contact us today to get started.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can One Printer Handle Both Primary and Secondary Packaging?

The MK-G Series can handle both in many cases, but the CC-1000 Series is a better fit for high-volume secondary coding.

How Does the Packaging Material Impact Coding Performance?

Material affects adhesion, contrast, and durability. Porous surfaces absorb ink well, while slick or coated ones may need fast-dry inks or UV laser marking for clean, readable codes.

Is Secondary Packaging Coding Required by Regulation?

Yes, especially in food, pharma, and retail. Case-level secondary packaging coding supports traceability, inventory tracking, and retailer compliance.

What Type of Packaging Materials Does the CC‑1000 Series Support?

The CC-1000 Series prints directly onto porous materials like uncoated corrugate and kraft board. It’s not suitable for glossy, waxed, or plastic-coated surfaces.

Can the MK‑G Inkjet Printer Be Used for Secondary Packaging?

Yes, with pigment inks on compatible materials. One of the limiting factors of the MK-G1000 vs the CC-1000 Series for secondary packaging is that the maximum print height on the MK-G1000 is much smaller than the CC-1000 Series.

How Does UV Laser Marking Differ from Inkjet Printing for Packaging?

UV laser coding alters the material’s surface without ink, making it ideal for primary packaging that demands clean, permanent, smudge-free marks. Inkjet offers broader material support but requires regular maintenance and consumables.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper