Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Comparing Continuous Inkjet Printer Inks

Continuous inkjet printers (CIJ), like the KEYENCE MK-G Series, are built to handle the fastest-paced production environments and deliver consistent and legible markings. These printers hold up under the most demanding conditions, whether marking plastic bottles, metal parts, or packaging film.

The KEYENCE MK-G Series printer offers flexible ink options for different surfaces and use cases. Most lines rely on either black dye-based ink or pigment-based ink in yellow or white. Both types of ink work for product coding, but ink selection directly affects print clarity and how consistently the system runs over time. Knowing the differences between the ink types can help production operators choose the correct ink for their application.

Comparing Black Dye Ink vs Yellow/White Pigment Ink

The composition and behavior of dye and pigment inks differ in ways that matter on the production line.

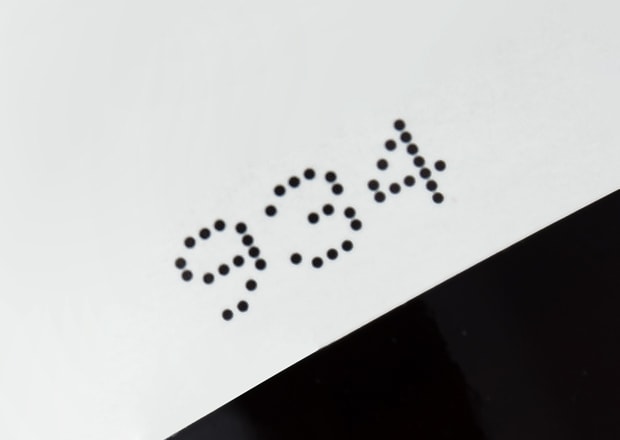

Black dye-based inks are wholly soluble. Their colorant dissolves into the liquid carrier, creating a smooth and uniform solution. Dye-based solutions flow easily through CIJ systems, minimizing buildup and stabilizing the print process. The results are crisp, legible markings that dry quickly and are ideal for high-speed, high-volume applications.

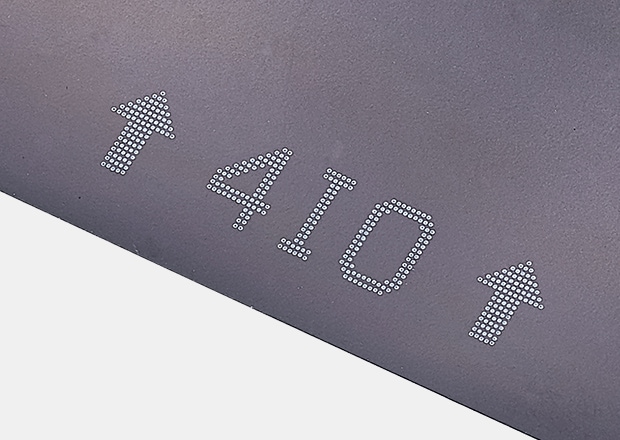

On the other hand, yellow and white pigment-based inks contain solid particles suspended in a fluid. The particles do not dissolve, giving pigment ink its opacity, which makes it effective for printing on dark and colored surfaces. However, this benefit of pigment ink also makes it harder to manage. The pigment particles will settle over time unless the solution is continuously mixed or agitated. This can lead to clogs and inconsistent print quality in CIJ printers if the system isn’t prepared to handle the ink properly.

Regarding visual quality, dye inks typically offer more vibrant inks with smoother edges, and pigment inks provide strong contrast against dark backgrounds but appear slightly less sharp on light-colored materials. The trade-off between speed and surface contrast is key in choosing the right ink type.

Curious about our pricing?

Click here to find out more.

Key Differences Between Black Dye Ink and Yellow/White Pigment Ink

Ink composition isn’t the only factor separating black dye ink from yellow or white pigment ink. The way these inks interact with a CIJ and the types of maintenance they require create a clear divide for the day-to-day operations of each solution.

Dye-based ink runs cleanly through CIJ printers. These inks are easier on internal components like filters, valves, and nozzles and require less frequent cleaning, which means there are fewer interruptions for flushing cycles or printhead servicing. Dye-based inks are an excellent option for manufacturers who prioritize stability and minimal downtime.

Pigment inks have more impact on a CIJ printer, and they are harder to manage once they are inside the system. These inks are only effective in pigment ink-compatible CIJ printers that are equipped with specialized stirring mechanisms and stronger filtration systems. Even with those in place, more regular maintenance is required to keep print quality consistent and to help avoid failures caused by sediment buildup.

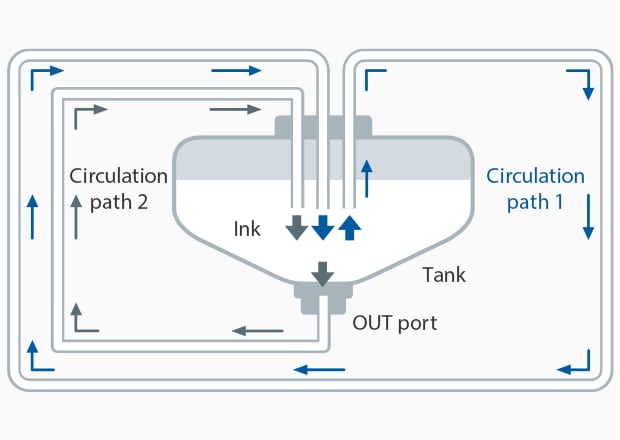

Dual Circulation System

The new structure of the MK-G Series prevents precipitation and solidification of pigment inks by constantly circulating the ink during operation.

* Included with MK-G1000PY/PW models.

When to Choose Black Dye Ink Over Yellow/White Pigment Ink

Black dye ink is often the better choice for high-speed continuous inkjet productions, especially when printing on lightly-colored or neutral materials. Dye ink is also more cost-effective as it is easier to manufacture, and its printers typically need less maintenance. Dye ink is perfect for general-purpose applications that do not require high-contrast printing on dark surfaces.

Discover more about this product.

Click here to book your demo.

When to Choose Yellow/White Pigment Ink Over Black Dye Ink

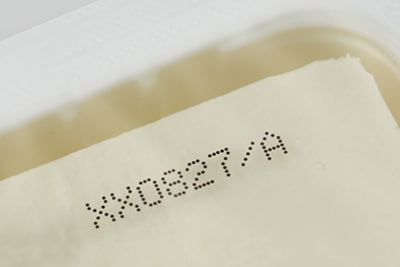

Yellow and white pigment inks are often the best options for dark or reflective surfaces. Applications like cables, rubber parts, and black plastic often need higher-opacity inks for clear visibility; they are better resistant to UV rays, moisture, and abrasions. Pigment inks are commonly used on products intended for use in industries like automotive and electronics.

Industries That Benefit Most from Each Ink Type

Dye-Based Inks

- Food and Beverage: Ideal for printing lot codes, expiration dates, and labels on pouches, cartons, and PET bottles.

- Pharmaceuticals: Used on blister packs, folding cartons, and secondary packaging.

- General Packaging: Performs well on light-colored materials with minimal maintenance, supporting continuous production.

Pigment-Based Inks

- Wire and Cable: Commonly used for coding black insulation, tubing, and cable jackets with high-opacity white or yellow ink.

- Automotive and Aerospace: Suitable for marking rubber, metal, and plastic components exposed to heat, abrasion, and vibration.

- Electronics: Used for permanent marking on dark or reflective plastic housings, connectors, and other low-contrast surfaces.

Choosing the Right Ink for Your Continuous Inkjet Printer

When using a CIJ printer, ink selection comes down to what material is being printed on and how the production line is configured. Industrial inkjet printers don’t all support pigment inks, so hardware compatibility is the first checkpoint. From there, operators need to evaluate substrates, the production environment, and their expected downtime tolerance. Pigment may be necessary if the print needs to survive abrasion or low-contrast surfaces. Dye is often the more efficient choice for faster lines and simpler setups.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Black Dye Ink vs. Yellow/White Pigment Ink in KEYENCE CIJ Printers

Can I Switch Between Black Dye Ink and Yellow/White Pigment Ink in My KEYENCE Printer?

No, our printers are designed specifically for the type of ink intended for use to ensure consistency and quality across all our products. You cannot swap dyes/pigment colors.

How Long Will the Markings Last When Using Yellow/White Pigment Ink?

Pigment inks are known for their fade resistance and durability. They offer long-lasting visibility on dark or exposed surfaces, even under UV or abrasive conditions.

Does Pigment Ink Dry Faster Than Dye Ink?

No. Dye ink typically dries faster.

Does the Type of Surface Affect the Performance of Each Ink?

Both are extremely capable of applying to most materials. Dye ink has the best contrast on light, absorbent materials. Pigment ink has more contrast on dark or non-porous substrates.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper