Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Concerned about Missing or Poor-Quality Codes? Here’s the Print Inspection Solution

Expiration dates support traceability through the supply chain and guarantee that customers get what they pay for. However, during the process of manufacturing and packaging, codes can become faded or smudged. This leads to unhappy customers, a loss of trust, and, in some cases, issues with compliance, leading to serious consequences.

To tackle this issue, KEYENCE has developed and produced their MK-G Series continuous inkjet printer (CIJ). This advanced machine not only codes and marks packaging at a high level, but it also has the functionality to integrate with vision systems. Vision technology and high-speed printing together create a package that verifies top-quality code placement and quality in all applications through CIJ technology and constant inkjet printing inspection.

Detecting Errors with Print Inspection Devices

Inkjet printers are not the only cause of missing characters in printed text. Other possible causes include the vibrations of packaging machines and variations between package size, shape, and material. Performing inspections with a vision system is an effective method for handling the rare case of printing mistakes. It provides another barrier to unacceptable coding or marking making its way off the manufacturing line.

Installation with No Unnecessary Costs

In order to synchronize a message printed by any inkjet printer with a vision inspection system on a conventional inkjet, software is required at an additional cost.

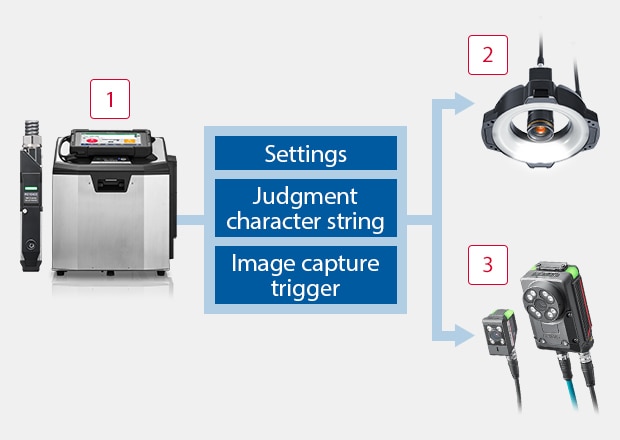

With the MK-G Series, these devices can be connected easily with a single cable, which enables printing inspections with no unnecessary costs for creating software.

The vision system settings can be configured as a batch from the inkjet printer screen. The combination of providing printing and inspections in one easily connectable printing inspection system, along with ease of setup, makes the MK-G Series invaluable for manufacturers.

When the settings on the inkjet printer are switched, the settings on the vision system are automatically switched to match.

Prevents Mistakes When Choosing Settings

With conventional systems, it was inevitable that inspection mistakes would occur due to incorrect selections when setting the inkjet printer and the vision system separately. When printing settings are switched on the MK-G Series, the inspection settings on the vision system are automatically switched to match, which enables mistake-free inspections.

-

1Continuous Inkjet Printer MK-G Series

-

2Intuitive Vision System CV-X Series

-

3Vision Sensor with Built-in AI IV4 Series

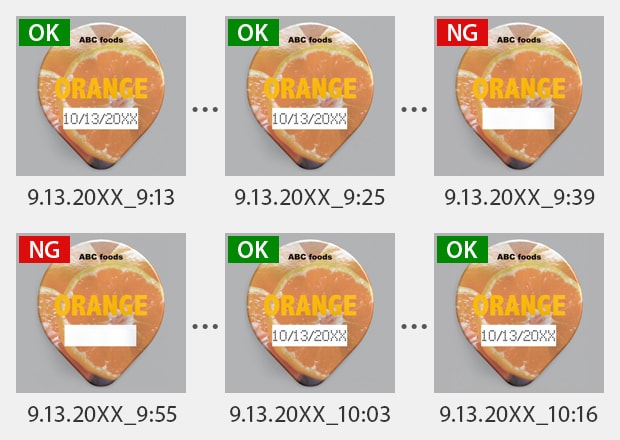

Print Inspection History

Capture data storage:

Image data captured using an IV4 Series Vision Sensor can be saved to a USB memory device and retrieved to check inspection results even after a product has shipped. This is useful for tracing the causes of problems and adjusting settings to make sure the issues don’t continue.

Get detailed information on our products by downloading our catalog.

View Catalog

Master Vision System Functions to Increase Print Inspection Quality

KEYENCE vision systems go beyond simple text inspection, offering advanced features tailored for food manufacturing facilities. It is easy to connect devices, and this section introduces the additional value provided by these functions.

Inspections can be performed not only for the date but also for flaws and dirt at the same time.

Product Type Differentiation and Inspection for Dirt Can Be Performed at the Same Time

In addition to inspections of printed text, it is also possible to inspect for other defects on the printed surface at the same time. The vision system can be used to perform a variety of operations at the same time, such as product type differentiation and inspection for dirt. This allows advanced inspections with easy configuration: just read a non-defective workpiece.

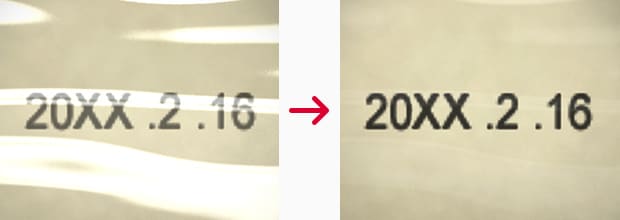

Glare, which affects inspections negatively, is eliminated to enable stable inspections.

Also Excels at Inspections of Printed Text on Film

With glossy films, it was generally difficult to obtain stable inspection results. KEYENCE’s newly developed ultra-high-speed camera and partial lighting illumination reduce glare, which has greatly improved the stability of film inspections. The combination of reliable non-contact printing and accurate print inspections means that the percentage of products that reach the customer with perfect codes increases drastically.

We’re here to provide you with more details.

Reach out today!

Take Your Inspections to the Next Level with KEYENCE Inkjet Code Printers

The KEYENCE MK-G Series CIJ can be vital for manufacturing facilities aiming to elevate product and print inspection. These printers combine cutting-edge technology with an easy-to-use interface to provide fast, flawless, and frustration-free code printing.

One feature that makes the MK-G Series stand out is its ability to integrate seamlessly with vision systems, creating a printing inspection system. This brings real-time error detection and correction capability onto the printing line, which ensures that all coding and marking are consistently precise. For manufacturers, this translates into saved time and money, a reduction in waste and downtime, and constant improvements. The data collection and analysis process will also be enhanced by this integration, with the vision systems providing insights into any issues or areas for improvement.

Improve your printing inspection system with the KEYENCE MK-G Series inkjet printers. Designed for vision system integration, they ensure real-time error detection and correction for precise, efficient results. Contact us today for a free demo.

Curious about our pricing?

Click here to find out more.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper

![Packaging Technology Introduction [Packaging Machine Edition]](/img/asset/AS_82098_L.jpg)