Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Eliminate Costly Service Contracts: How the KEYENCE MK-G Series Inkjet Printer Empowers In-House Maintenance

Maintaining continuous inkjet printers is costly and time-consuming, often requiring service contracts and specialized technicians. The KEYENCE MK-G Series continuous inkjet printer is designed with self-maintenance in mind, eliminating unnecessary service calls and putting control back in the hands of the user. Instead of waiting for a technician, operators can rely on its automated troubleshooting and intuitive interface to keep things running.

In industries like food and beverage, where code readability is crucial for accurate tracking, compliance, and food safety, a printer that takes care of itself is not just convenient—it's a practical, cost-effective solution that ensures traceability and minimizes risks to consumer health.

Tool-free part replacement with illustrated instructions

One-touch nozzle replacement

The Hidden Costs of Traditional Printer Maintenance

Legacy printers come with hidden expenses that compound over time:

- The Reliance on Field Technicians and Service Contracts

For years, companies have depended on service contracts to keep industrial barcode printers continually operating with minimal disruptions. These contracts add up quickly, which means businesses have to pay for regular maintenance and unexpected repairs. On-site visits from technicians aren’t just costly; they also lead to delays and inefficiencies. - Downtime Costs: How Waiting for Repairs Impacts Production

Production lines depend on reliable CIJ printing for product identification, regulatory compliance, and traceability. When a printer malfunctions, every minute spent waiting for a technician results in lost production and revenue. Unscheduled downtime can lead to costly delays in shipping and distribution. - Expenses Associated with Skilled Labor for Printer Operation

Operating and maintaining traditional continuous inkjet printers require trained personnel who understand the nuances of troubleshooting and upkeep, which means companies find themselves spending more money to train employees or hire specialists.

We’re here to provide you with more details.

Reach out today!

How the MK-G Series Inkjet Printer Brings Maintenance In-House

The MK-G Series brings smarter inkjet printer maintenance directly to your facility floor:

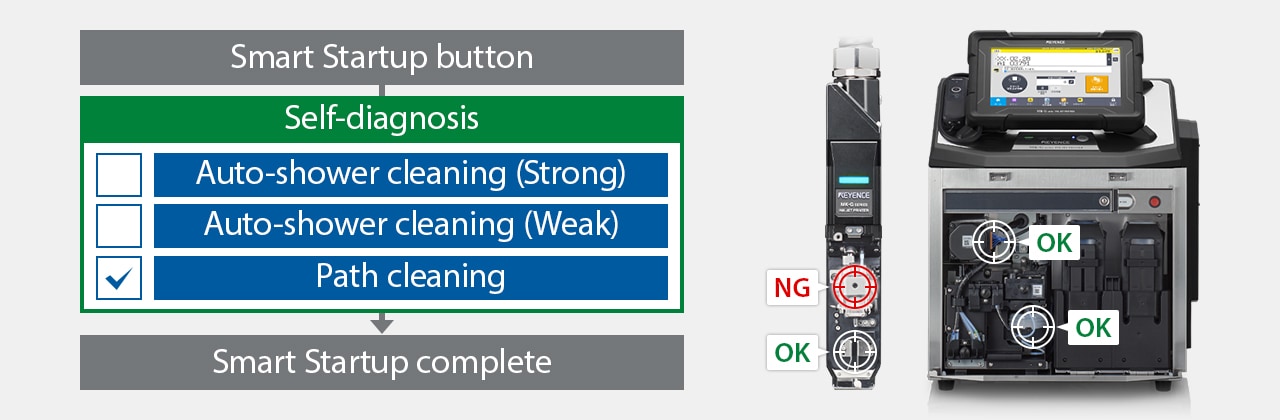

- Built-In Self-Diagnosis for Quick Troubleshooting

The KEYENCE MK-G Series is a reliable CIJ that incorporates an automated self-diagnosis feature that can take corrective action to clear clogs or adjust viscosity. Unlike conventional printers, the MK-G Series continuously monitors its internal conditions and detects potential issues before they escalate. - Intuitive Interface for Operator-Led Problem Resolution

Many industrial barcode printers require extensive employee training to operate effectively. The MK-G Series eliminates this barrier with an intuitive interface designed for ease of use. Operators can quickly assess printer status, receive maintenance alerts, and follow step-by-step guidance for resolving minor issues. - Reducing the Need for Specialized Technicians

With the inclusion of automated inkjet printer maintenance capabilities, the MK-G Series eliminates the dependency on field technicians for routine servicing. The MK-G’s self-cleaning, automated ink management, and guided part replacements let companies handle maintenance in-house.

Eliminating Service Contracts: Cost Savings and Efficiency

Cutting service contracts reduces operating costs and boosts uptime:

- How Self-Troubleshooting Reduces Service Calls and Maintenance Fees

The MK-G Series’ ability to self-diagnose and correct errors significantly reduces the need for external services. With its smart startup and shutdown functions, the printer makes sure that maintenance occurs only when necessary, lowering overall expenses. - Faster Issue Resolution Compared to Waiting for a Technician

In conventional setups, even minor printer malfunctions can result in prolonged downtime as businesses wait for a technician to arrive. The MK-G Series improves issue resolution with real-time monitoring and remote diagnostics. Operators can access printer status updates via a web console, allowing them to identify and address concerns without external intervention. - Avoiding Unexpected Repair Costs with Predictive Maintenance

Unexpected breakdowns often lead to unplanned expenditures, as emergency repairs and replacement parts can be costly. The MK-G Series mitigates this risk through predictive maintenance, monitoring key components, and alerting operators before failures occur, which helps extend equipment lifespan and optimize performance.

Curious about our pricing?

Click here to find out more.

Real-World Benefits for Manufacturers

Self-maintenance is a competitive advantage for manufacturers and can allow them to get ahead. Here’s how:

- A Side-by-Side Comparison of Service Contract Dependency

Manufacturers relying on traditional continuous inkjet printers must factor in the long-term costs of service contracts, which include labor fees, replacement parts, and extended downtime. The MK-G Series removes these issues as it offers a self-sufficient alternative that requires minimal intervention. - Competitor Models vs. the MK-G Series’ Autonomous Troubleshooting

While many competitor models boast high-speed printing, they still require frequent inkjet printer maintenance and technical oversight. The MK-G Series sets itself apart with its hands-free cleaning system, built-in viscosity adjustments, and error-prevention technology. - The Advantage of KEYENCE Support Without Ongoing Fees

Unlike printers, which have a constant cost, the MK-G Series offers reliable CIJ assistance without additional fees. Its user-friendly maintenance design and remote monitoring capabilities allow businesses to manage their printing systems independently while still having access to the KEYENCE support network when needed.

How MK-G Series Stands Apart from Competitor Inkjet Printers

The MK-G Series sets a new standard for high-demand production with intelligent automation, advanced diagnostics, and adaptive ink handling. Unlike traditional CIJ systems, it offers exceptional autonomy, reliability, and cost efficiency, making it perfect for seamless, efficient operations:

- Regular Maintenance and Inspection Recommendations

The MK-G Series’ easy-to-use CIJ automated system lets operators monitor ink levels, nozzle conditions, and overall system health through real-time diagnostics. However, regular hardware checks ensure optimal performance. - Best Practices for Selecting and Handling Printer Inks

To preserve print clarity and adhesion, the MK-G Series supports a variety of ink formulations, which include those optimized for food and beverage packaging. Proper storage and handling further maintain print quality and compliance with industry standards.

Future-Proofing Your Production Line with KEYENCE MK-G Series

Self-sufficient printers like the MK-G Series reduce wear and tear by providing consistent ink flow and preventing clogs before they develop. These features contribute to prolonged operational efficiency and reduce the likelihood of unexpected failures.

- The Role of Technology in Reducing the Need for External Service

Advancements in adaptable technology made by the MK-G Series continuous inkjet printer, like real-time viscosity adjustments and automatic self-troubleshooting, eliminate many of the common challenges associated with traditional printers. - Why Food and Beverage Companies Are Switching to Self-Sufficient Solutions

The MK-G Series is an easy-to-use CIJ that empowers food and beverage companies to take full control of their printing processes. It delivers precise, high-quality barcodes on food labels, which not only helps reduce compliance risks but also enhances traceability, making it an essential tool for maintaining safety and efficiency in the industry.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Does the MK-G Series Compare in Durability to Competitors That Require Service Contracts?

The MK-G Series has a rugged design that can withstand harsh industrial environments. This reduces the need for frequent repairs.

What Are the Most Common Maintenance Issues That the MK-G Series Can Self-Diagnose?

Ink viscosity imbalances, nozzle clogs, and ink path obstructions are automatically detected and resolved by the system.

Does the MK-G Series Require Specific Training to Operate Its Self-Troubleshooting Features?

No. The user-friendly interface and smart dock allow for simple and automatic self-troubleshooting.

How Does the MK-G Series’ Self-Maintenance Impact Long-Term Operational Costs?

With a reduction in service calls and technician fees, businesses can save significant money on maintenance and repair.

What Happens if an Issue Arises That the MK-G Series Cannot Resolve on Its Own?

KEYENCE provides additional support for issues that the automated system cannot resolve.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper