Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Guide to Inkjet Printing Viscosity and Optimization

Viscosity is crucial for achieving high-quality inkjet prints, as it affects ink behavior through the printer's nozzle and onto the substrate. The KEYENCE MK-G Series automatically regulates viscosity in real time, ensuring consistent print quality and reducing the need for manual adjustments.

Understanding Viscosity and Its Impact on Inkjet Printing

Viscosity plays a critical role in achieving consistent, high-quality inkjet prints. It affects ink behavior as it moves through the printer’s nozzle and onto the substrate, influencing droplet formation, ink distribution, and adhesion.

Inkjet printing viscosity is essential for optimizing print quality. Too low viscosity can lead to smudging and blurry prints, while high viscosity can cause clogging and printhead failures. Factors like temperature, humidity, and ink composition can also affect viscosity, which is why the MK-G Series is designed to regulate and adjust viscosity in real time to prevent defects and maintain consistent results.

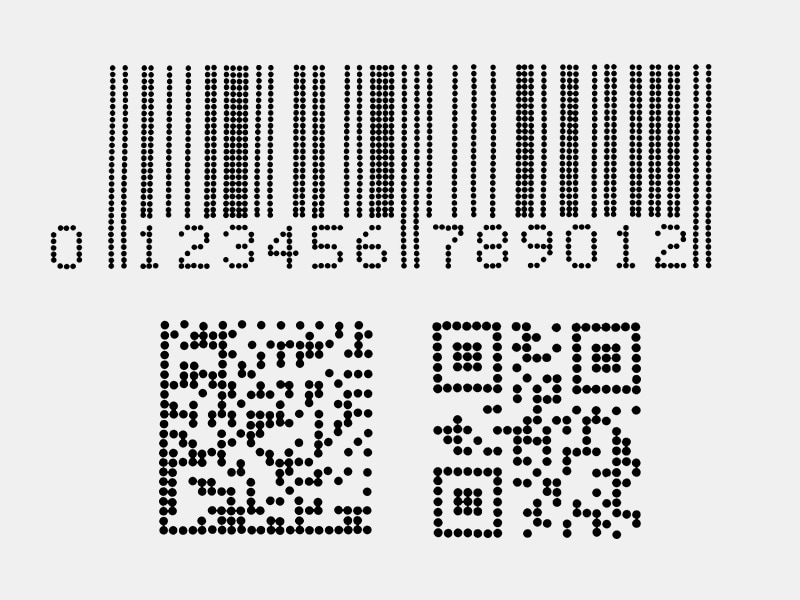

Less-than-optimal state of particles

Optimal particle state

In this article, we will discuss how the Continuous Inkjet Printing MK-G Series from KEYENCE is designed to automatically regulate viscosity and make real-time adjustments, which helps prevent printing defects and enhance overall throughput.

We’re here to provide you with more details.

Reach out today!

How Inkjet Printers Like the MK-G Series Handle Viscosity

Traditional CIJ printers require manual viscosity adjustments and rely on operators to monitor and maintain ink consistency. However, the MK-G Series employs a conditioning tank and viscosity sensors that make sure the inkjet ink remains stable, regardless of environmental conditions.

The automated system continuously monitors ink properties and makes adjustments in real time, eliminating the need for operator intervention and allowing for uninterrupted, high-speed printing with consistent results. Additionally, the MK-G Series has an auto-shower cleaning function that prevents ink buildup inside the printhead. This buildup negatively affects inkjet printing viscosity over time.

Overcoming Viscosity Challenges in Inkjet Printing and Solutions with a Conditioning Tank

Proper ink viscosity is key to consistent print quality in CIJ printing. The KEYENCE MK-G Series addresses this with its advanced four-tank design and real-time viscosity control, outperforming traditional three-tank systems.

How the Conditioning Tank Prevents Viscosity Degradation

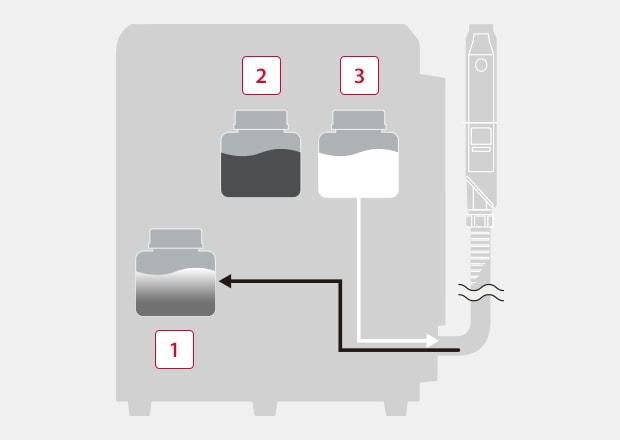

Traditional CIJ printers use a three-tank system: main tank, ink tank, and solvent tank. During cleaning cycles or extended downtimes, solvent can flow back into the main tank, diluting the ink-to-solvent ratio. This results in poor viscosity control, leading to:

- Inconsistent droplet formation

- Printhead clogging

- Substandard print quality

- Increased downtime and maintenance costs

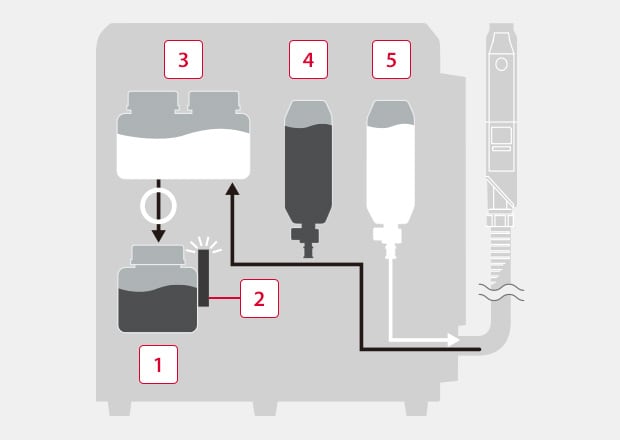

The MK-G Series eliminates this problem by introducing a conditioning tank, a fourth tank that isolates cleaning solvent during maintenance routines. Rather than contaminating the main tank, solvent is redirected to the conditioning tank, preserving the integrity of the ink formulation in the main tank.

Without Conditioning Tank

When washing is performed, the ink viscosity decreases.

-

1Main tank

-

2Ink tank

-

3Solvent tank

MK-G Series

The conditioning tank is used for temporary storage to prevent dilution of the ink.

-

1Main tank

-

2Viscosity sensor

-

3Conditioning tank

-

4Ink cartridge

-

5Solvent cartridge

Real-Time Viscosity Management with Smart Sensing

To maintain consistent viscosity, the MK-G Series includes a built-in viscosity sensor that continuously monitors the ink’s condition. When deviations are detected, the system automatically adjusts the ink-to-solvent ratio by adding solvent from the conditioning tank. This ensures that the ink remains within optimal parameters without manual intervention. This reduces solvent waste, minimizes print errors, and reduces frequency of downtime to clean the printhead.

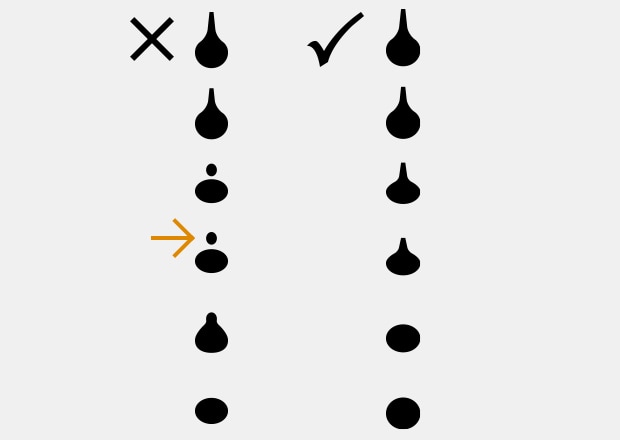

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

Ink Particle Optimization for Print Clarity

In addition to viscosity control, the MK-G Series uses an Ink Particle Optimization (IPO) sensor that checks the ink's breakpoint 10 times per second. This helps compensate for viscosity shifts caused by temperature changes or frequent cleanings. By maintaining a stable ink particle state, the IPO sensor prevents splatter, ensures clean droplet formation, and delivers sharp, high-resolution print quality across production runs.

Curious about our pricing?

Click here to find out more.

Temperature and Viscosity: Key Considerations for Consistent Printing

Temperature fluctuations can greatly impact ink viscosity, which affects print quality and consistency. As ink temperature decreases, viscosity increases, causing the ink to thicken. This can lead to sluggish ink flow, nozzle clogging, and inconsistent print results. Alternatively, high temperatures cause viscosity to decrease, making the ink too thin. This results in over-spraying, smudging, and poor adhesion to the substrate.

Maintaining optimal viscosity at different temperatures is crucial for ensuring high-quality prints, especially in high-speed industrial settings where production environments can experience frequent temperature changes. The MK-G Series addresses this challenge with real-time viscosity monitoring and automatic solvent adjustments, keeping ink fluid and consistent regardless of changes in temperature.

With advanced viscosity control, the MK-G Series automatically adjusts the ink's flow properties to maintain consistent printing, even in environments with fluctuating temperatures. This functionality helps businesses avoid downtime, reduce waste, and maintain top-quality prints no matter the conditions.

| Season | Temperature | Humidity |

|---|---|---|

|

Summer

|

Temperature

30°C 86°F

|

Humidity

70%

|

|

Fall

|

Temperature

23°C 73.4°F

|

Humidity

35%

|

Resistant to Seasonal Changes

Even when the ambient temperature or humidity changes with the seasons, the state of the ink particles is always optimal.

Benefits of Using MK-G Series for Consistent Viscosity Management

The MK-G Series is designed to take the guesswork out of viscosity management. Here are the key benefits that set it apart:

- Automated Viscosity Control: Eliminates the need for manual adjustments to maintain print consistency.

- IP55-Rated Protection: Prevents dust and moisture interference to ensure long-term reliability.

- Self-Troubleshooting System: The MK-G Series detects errors and adjusts as needed automatically to reduce downtime.

- Reduced Maintenance Needs: Auto-cleaning functions prevent clogging, which helps extend the lifespan of printheads and other components.

- Industry-Wide Compatibility: Works across multiple industries with the ability to adapt to different substrates.

- Performance Analysis: The hourly operation status of the MK-G Series is displayed on a graph. Visualize a wide range of information, including error counts, operating hours, temperature, and viscosity as far back as 100 days.

Discover more about this product.

Click here to book your demo.

Optimizing Your Printing with the Right Viscosity and MK-G Series

Ink management is simplified with the MK-G Series as it automatically regulates viscosity and consistently produces high-speed printing without interruptions. In high-speed industrial environments, interruptions can lead to costly downtime, but the MK-G Series maintains precise inkjet printing viscosity in real time while maintaining uninterrupted printing.

The MK-G Series can benefit most businesses with:

- A smart, easy-to-set-up interface

- Clear and long-lasting print clarity

- Minimized ink and solvent waste

- Extend the lifespan of printheads

- Reduced maintenance costs

- Improved productivity with uninterrupted printing

With smart features like viscosity control, automated cleaning, and self-diagnosis, it’s built to keep operations running smoothly. The MK-G Series is your go-to solution for cost savings and lasting print quality.

Contact KEYENCE today to request a free demo or download the MK-G Series technical catalog to learn how automated viscosity control can improve your production process.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs on Guide to Inkjet Printing Viscosity and MK-G Series Optimization

Can Viscosity Be Adjusted Automatically on the MK-G Series?

Yes, the MK-G Series features real-time viscosity monitoring and adjustment; this helps keep ink consistent without manual intervention.

What Types of Substrates Are Most Affected by Viscosity Levels in Inkjet Printing?

The substrate will determine which viscosity level to use. For non-porous materials like glass and plastic, a higher viscosity ink is required for proper adhesion. Other porous substrates, like cardboard or paper, work best with a lower-viscosity ink to prevent excessive absorption and ink feathering.

How Can I Determine the Ideal Viscosity for My Specific Printing Job?

The MK-G Series eliminates the guesswork. It continuously analyzes environmental conditions, ink properties, and substrate types and makes adjustments to viscosity to maintain peak performance.

How Does the MK-G Series Compare to Other Printers in Terms of Viscosity Control?

Unlike conventional CIJ printers, which require manual viscosity checks and adjustments, the MK-G Series automates the entire process; it also works to reduce errors, increase uptime, and maintain superior print quality.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper