Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

How MK-G Series Simplified CIJ Maintenance Tech Frees Up Time for Skilled Workers

Industries like manufacturing traditionally depend on skilled technicians to operate and maintain equipment, especially Continuous Inkjet printers (CIJs). These printers are essential for printing labels and codes on a variety of materials, such as plastic, glass, and metal. Despite their significance, keeping even low-maintenance CIJ printers operational can often be a time-consuming and labor-intensive task.

The Challenges of Traditional CIJ Systems

Traditional continuous inkjet coders present a range of challenges and drawbacks that should be considered:

- Maintenance: A key challenge with conventional CIJ is they require frequent, heavy maintenance just to keep running. This includes regular upkeep, daily cleaning, and filter replacements.

- Training: Traditional continuous inkjet coder systems require specialized training for operation and maintenance, leading to additional hiring and training time for manufacturers.

- Manual Troubleshooting: Traditional CIJ systems also have limited self-diagnostic capabilities, forcing operators to troubleshoot issues, which can lead to long production halts.

- Need for Specialized Technicians: Despite all of the above requirements, a visit from a specialized service tech or even a service contract is needed. This is generally quite costly and will include notable downtime while waiting for the technician to arrive.

Head cleaning

Solvent refilling

Filter replacement

We’re here to provide you with more details.

Reach out today!

Benefits of the KEYENCE CIJ Series Over Traditional CIJ Systems

The KEYENCE CIJ offers advantages over traditional continuous inkjet coder systems:

1. Enhanced Self-Analysis Capabilities

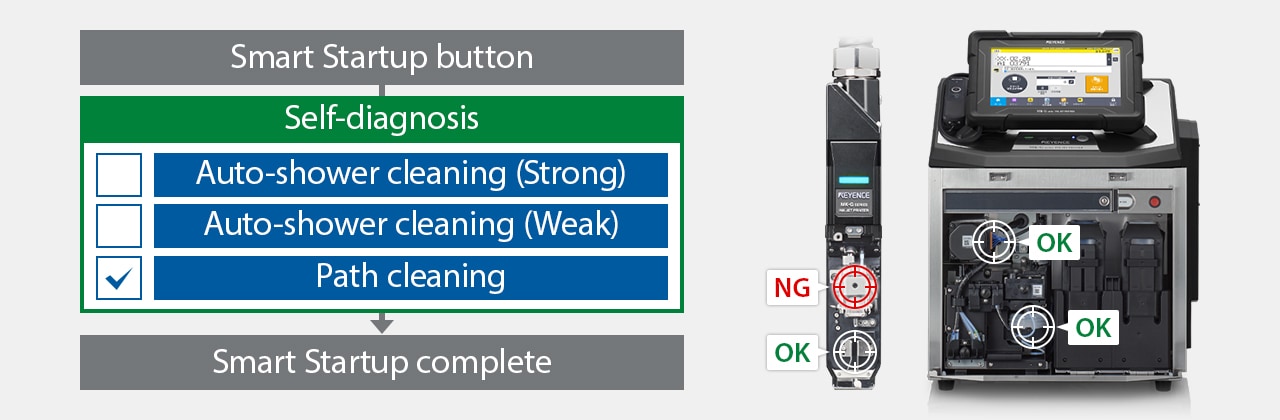

The KEYENCE CIJ provides self-analysis and troubleshooting capabilities, minimizing downtime and reducing staff troubleshooting time. Operators simply push a button, and the printer will decide what/if any cleanings or maintenance are required prior to running production.

Using the MK Dock enables self-diagnosis and cleaning to ensure stable startup.

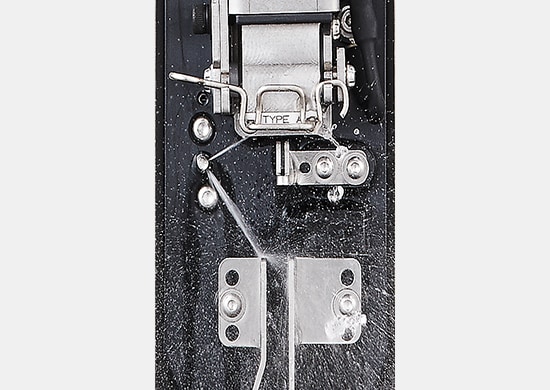

2. 1-Touch Replaceable Nozzle

The KEYENCE CIJ provides a notable advantage over traditional Continuous Inkjet (CIJ) systems with its convenient one-touch nozzle replacement feature. This process requires no tools or specialized skills, enabling any team member to replace clogged nozzles in under a minute, providing immediate relief to the most common CIJ issue.

3. IP55-rated Head & Controller and Drop Protection

The KEYENCE CIJ MK Dock, head, and Operation Assist Camera boast an IP55 rating, offering excellent dust and low-pressure water protection. It also has a MIL standard-compliant drop-resistant structure. This indicates that the printer and its components, such as the head, console, and Operation Assist Camera, are designed to withstand accidental drops without compromising performance. These features ensure the system can endure harsh industrial environments without affecting performance.

Curious about our pricing?

Click here to find out more.

Built-in Sensor Technology: Enhancing Self-Maintenance in Industrial Continuous Inkjet Printing

In industrial printing, continuous inkjet printers are preferred for their high-speed performance on various materials, but they need regular manual cleaning and calibration by trained technicians, which can be time-consuming.

The KEYENCE CIJ Series features improved self-maintenance with integrated sensor technology, unlike other conventional CIJ manufacturers, KEYENCE started as and remains a global leader in sensor technology. Incorporating this technology into our printers is unique and allows for a level of automation previously not found in the CIJ industry.

This innovative feature enables operation without the need for specialized technicians. It also features integrated sensor technology for automatic cleaning, eliminating manual cleaning found in other CIJ printers. This keeps internal components clean while reducing cleaning time.

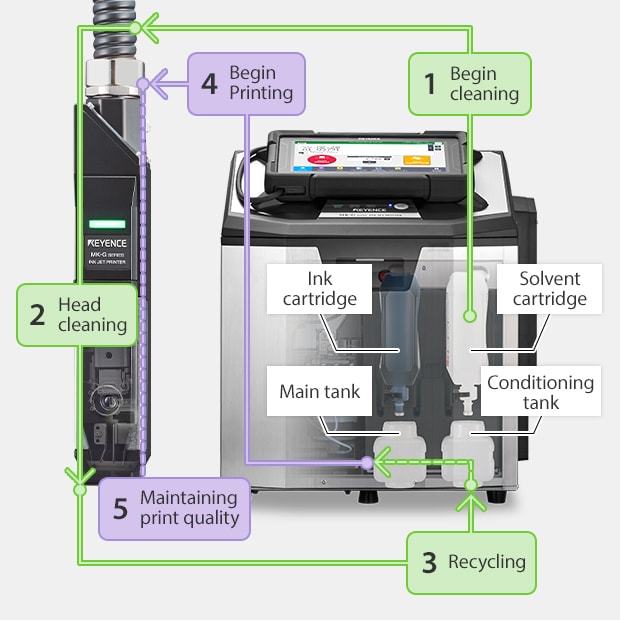

In the past, cleaning would cause the ink in the main tank to become diluted over time. The MK-G Series collects the cleaning liquid in a conditioning tank to ensure the ink does not become diluted. The concentration of the solvent collected in the conditioning tank is adjusted, and the solvent is then added to the main tank.

Discover more about this product.

Click here to book your demo.

Reducing Downtime with Automated Maintenance in Continuous Inkjet Coding

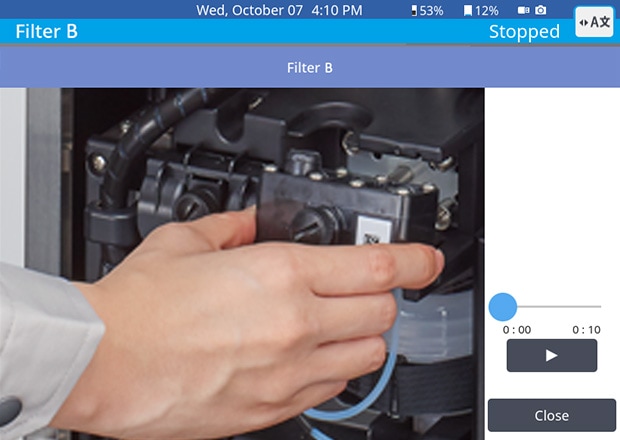

A key advantage of the KEYENCE CIJ is simple and tool free replacement filters and pumps. This innovation enables quick, efficient component changes, eliminating ink leak risks and reducing downtime. The procedure requires no specialized training, allowing skilled personnel to focus on other critical tasks.

Simply follow the instructional video for error-free replacement.

The KEYENCE CIJ also has videos and built-in guides with step-by-step maintenance instructions. These resources simplify tasks for operators with clear visual guides. This significantly cuts down the skills, time, and tools needed to maintain the MK-G Series.

We’re here to provide you with more details.

Reach out today!

Lowering Operating Costs Through Reduced Dependency on Skilled Labor

The demand for skilled technicians to operate and maintain complex equipment, such as continuous inkjet printers, can impose significant pressure on a company's budget. With the KEYENCE continuous inkjet printer, businesses can now reduce their operating costs.

The MK-G Series printer is designed for minimal maintenance, eliminating the need for costly service contracts commonly linked with traditional continuous inkjet printers. Consequently, businesses can achieve savings by avoiding expensive and time-consuming on-site visits or repairs.

Additionally, the simplified and automated maintenance technology of the KEYENCE CIJ minimizes downtime and reduces labor costs associated with equipment maintenance. By freeing up time for skilled workers from routine tasks such as cleaning printheads or changing filters, they can focus on more critical tasks and improve overall productivity.

All CIJs are just a tiny part of the process. The main focus of the maintenance staff is to ensure the machinery manufacturing your product is running as smooth as possible. Lot codes are generally small but required parts of this process that take up an abnormally large amount of time for conventional CIJ. The MK-G Series eliminates the time-consuming and labor-intensive maintenance tasks associated with conventional CIJ printers, allowing skilled workers to concentrate on more important tasks.

Conventional head cleaning

Manual cleaning was required to wash residual ink off the inside of the head.

Auto-shower cleaning

In addition to cleaning the ink paths, the key parts of the head are also subject to high-pressure cleaning. This negates the need for manual cleaning.

Curious about our pricing?

Click here to find out more.

Streamline Operations and Reduce Reliance on Skilled Labor with KEYENCE MK-G Series CIJ

The advancement of the 5th generation KEYENCE CIJ printer, particularly the MK-G Series, has transformed the operation and maintenance of inkjet printers. By integrating proprietary sensor technologies, this CIJ frees up time for skilled technicians and eliminates specialized product knowledge for its operation and upkeep. Additionally, its compact design and user-friendly interface facilitate seamless integration into existing production lines.

Reach out to KEYENCE today to discover how the MK-G Series can enhance your operations and minimize dependence on skilled labor.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Inkjet Printer Tech Guide [BASIC KNOWLEDGE EDITION]](/img/asset/AS_114378_L.jpg)

Continuous inkjet (CIJ) printers work by discharging ink particles to print information such as characters and figures on targets. This document describes the differences between industrial use inkjet printers and office-use printers, as well as their structures, circulation principles, and application examples.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper