Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Optimizing Operations with the MK-G Series: A Printer So Simple Anyone Can Maintain It

The MK-G Series is transforming production lines with advanced coding solutions that enhance efficiency and streamline operations. With cutting-edge technology and an intuitive interface, it’s the ideal tool for boosting productivity.

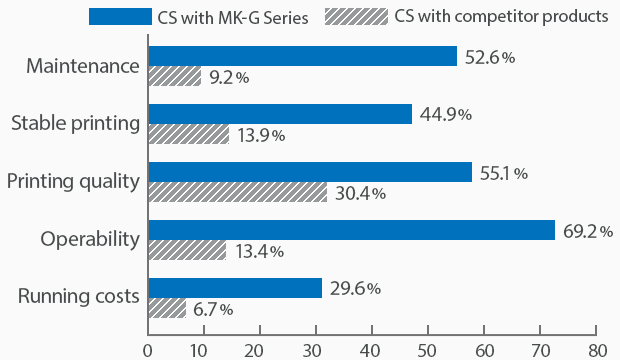

Customer satisfaction with the MK-G Series and competing products

The KEYENCE MK-G Series has five main areas where it reduces problems frequently encountered with continuous inkjet printers, which have earned the MK-G Series its favorable reputation when compared to competing products.

Addressing Industry Challenges with Continuous Inkjet Printer Maintenance

Industries that depend on printing technology face issues such as frequent industrial inkjet printer service and maintenance needs. Traditional printers often rely on skilled technicians, which can drive up costs, cause delays, increase errors, and lead to downtime.

The challenges faced by industries are now more manageable with continuous inkjet printers. With its self-cleaning feature, the MK-G Series keeps critical print head components spotless, delivering consistent, high-quality results every time. This feature also prevents clogs that affect performance and eliminates the need for manual disassembly by a technician.

We’re here to provide you with more details.

Reach out today!

Why the MK-G Series Stands Out as the Easiest Industrial Inkjet Printer to Operate

Industrial inkjet printers often struggle with complex setups and maintenance for continuous inkjet printers. The MK-G Series is an easy-to-operate industrial inkjet printer, as it makes cleaning effortless with its Smart Startup button. With just one press, it evaluates the device’s status and selects the perfect cleaning method. Its emergency shutdown mechanism also safeguards the printer during power outages.

The MK-G Series goes beyond basic maintenance with interactive troubleshooting displayed on the console. Clear, illustrated instructions help even less experienced personnel resolve issues, boosting efficiency, reducing downtime, and cutting costs.

Real-Time Environmental Adjustments for Perfect Print Quality

Ink particles are sensitive to different factors in their surroundings:

- Temperature

- Humidity

- Airflow

These can all dramatically impact their behavior and, ultimately, the quality of the prints. Traditional printers often require manual adjustments to address these variables, a process that is both time-intensive and susceptible to human error.

The MK-G Series date and lot code printer introduces a solution, equipped with advanced sensors that monitor ink particle behavior at a rate of 10 times per second. With real-time data, it fine-tunes ink viscosity and temperature, providing flawless print quality.

Resolves Printing Errors Caused by Temperature Fluctuations

The optimum ink particle status for printing is always fluctuating due to the ambient temperature and ink thickness (viscosity).

The MK-G Series inkjet printer senses the ink particles 10 times per second, which enables it to continually maintain the optimum ink particle status.

This maintains perfectly printed text at all times, regardless of the surrounding environment.

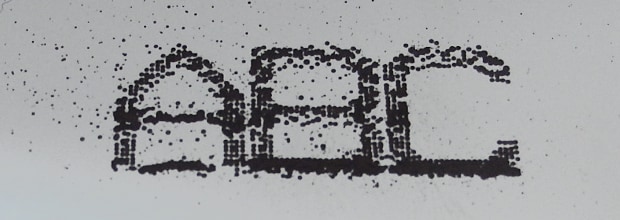

If the optimum ink particle status is not maintained, the inside of the head becomes dirty and unstable text occurs.

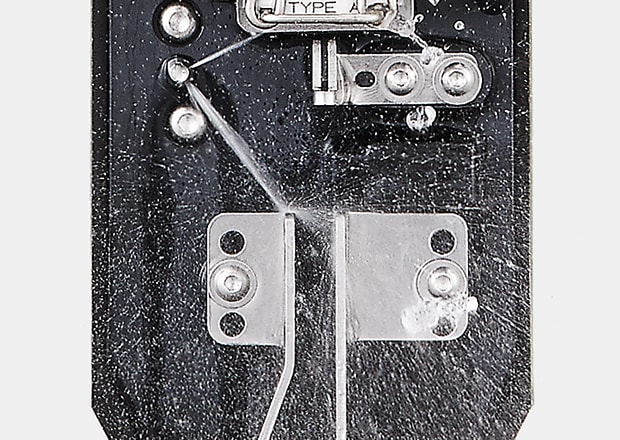

Dirt within the print head

Unstable text

| Conventional | MK-G Series |

|---|---|

|

Conventional

It’s necessary to make adjustments for the ink viscosity and temperature of the environment while visually checking the particle status.

|

MK-G Series

Ink particles are sensed and adjustments are automatically made to ensure the optimum particle status.

|

Sustainability and Cost Efficiency in CIJ Code Printer Operations

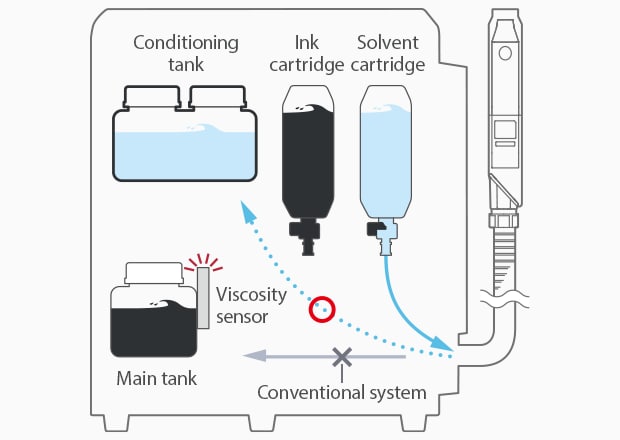

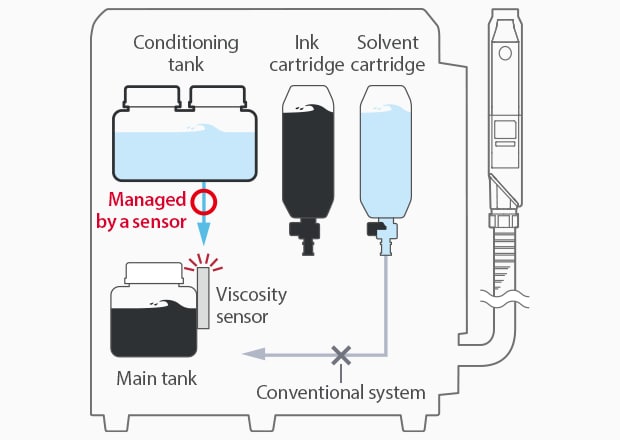

The device is equipped with a specialized tank (the conditioning tank) and a viscosity sensor for use in collecting the solvent after cleaning.

Doing this prevents ink dilution, which stabilizes viscosity and maintains perfect print quality.

During automatic cleaning

After automatic cleaning, the solvent is routed directly to the conditioning tank. This alleviates over-dilution of the ink stored in the main tank.

During viscosity management

The ink viscosity in the main tank is measured. Based on this reading, solvent is supplied to the main tank from the conditioning tank.

Nothing is wasted because priority is given to the conditioning tank.

Conventional automatic cleaning only used solvent to clean the ink paths. With the newly installed auto-shower function, the MK-G Series is able to clean the ink path and all the parts that are key to maintaining print quality all at once.

Conventional automatic cleaning

Only the ink paths are cleaned with solvent. Separate manual cleaning is required for any other dirty parts.

Auto-shower cleaning

In addition to cleaning the ink paths, the key parts of the head are also subject to high-pressure cleaning. This eliminates the need for manual cleaning.

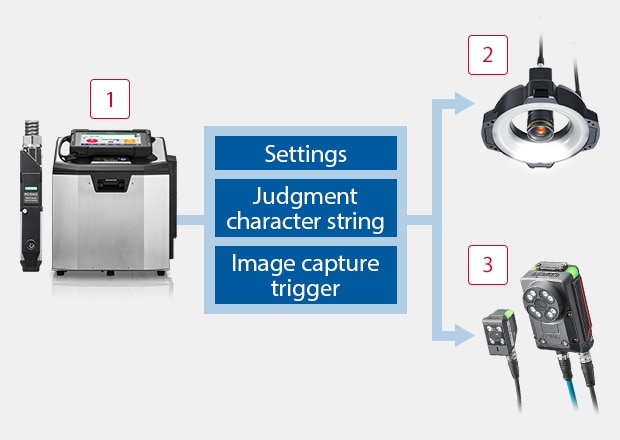

When the settings on the inkjet printer are switched, the settings on the vision system are automatically switched to match.

Simplified Installation and Reduced Operator Errors

With conventional systems, it was inevitable that inspection mistakes would occur due to incorrect selections when setting the date and lot code printer and the vision system separately. When printing settings are switched on the MK-G Series, the inspection settings on the vision system are automatically switched to match, which enables mistake-free inspections.

The devices can be connected with a single LAN cable.

-

1Continuous Inkjet Printer MK-G Series

-

2Intuitive Vision System CV-X Series

-

3Vision Sensor with Built-in AI IV4 Series

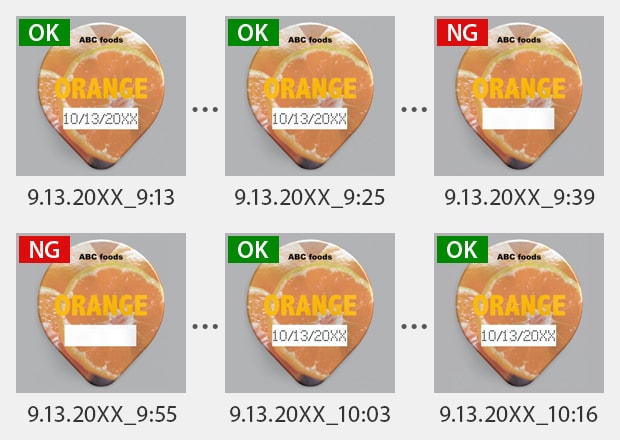

Save captured data to check inspection results for shipped products.

Image data captured using an IV4 Series Vision Sensor can be saved to a USB memory device and retrieved for checking inspection results even after a product has shipped. This is useful for tracing the causes of problems.

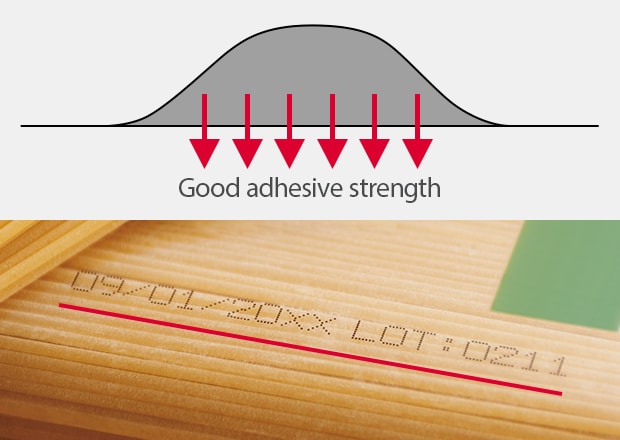

Super-Adhesive Ink for Versatile Applications

The adhesive substance in the ink, known as the ink binder, is improved to conform with even polyether resin materials, which were difficult to print on with conventional inks.

Our new ink also features increased adhesion on other materials.

Conventional ink

Printed text rubs off with conventional inkjet ink.

Super-adhesive ink

Super-adhesive ink stays on firmly.

Single Cable Connection for Vision Systems

In order to synchronize a message printed by any inkjet printer with a vision inspection system on a conventional inkjet, software is required with an additional cost.

Just one cable needed to connect, with no extra costs.

With the MK-G Series, these devices can be connected easily with a single cable, which enables printing inspections with no unnecessary costs for creating software.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Inkjet Printer Tech Guide [BASIC KNOWLEDGE EDITION]](/img/asset/AS_114378_L.jpg)

Continuous inkjet (CIJ) printers work by discharging ink particles to print information such as characters and figures on targets. This document describes the differences between industrial use inkjet printers and office-use printers, as well as their structures, circulation principles, and application examples.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper