Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

The Impact of Quality and Traceability Solutions for Coding on Dairy Products

Quality and traceability of products are two important production aspects dairy companies must get right. To ensure that milk, yogurt, cheese, and other dairy products meet regulatory and consumer quality standards, manufacturing companies must invest in printers that ensure clear, accurate, and durable lot/date coding. The right system also helps during traceability efforts in case of product recalls.

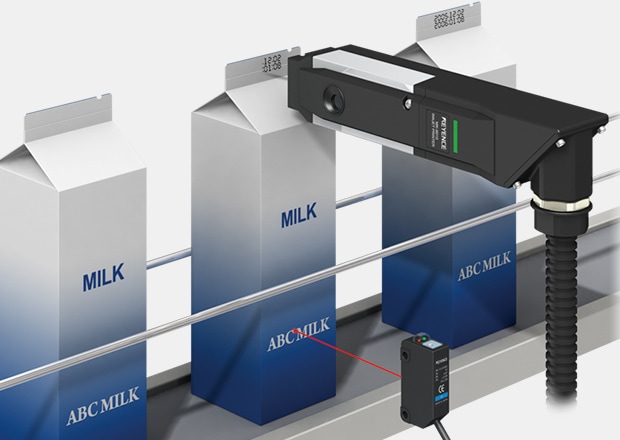

Installation example

Explore how continuous inkjet printers (CIJs) can help improve the quality of prints, such as the expiration date when coding dairy products. Learn also why manufacturers desire KEYENCE MK-G Series CIJ printer solutions.

Understanding Lot/Date Coding on Dairy Product Packaging

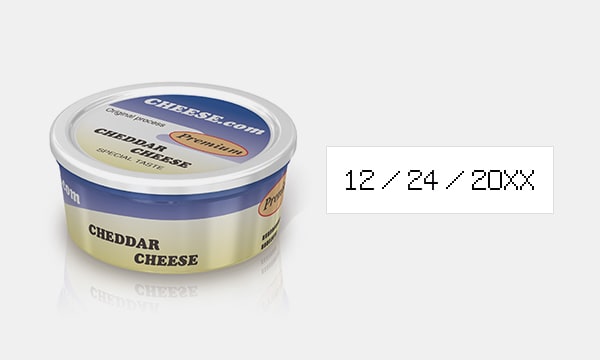

Lot coding is usually a mix of unique numbers and letters that identifies a specific batch or production run. On the other hand, date coding is the printing or coding of production or expiration date information on a product’s primary and or secondary packaging.

The structure of lot codes is formed based on information such as production date, shift, line number, and sequential number. These data types are used to create a unique combination of letters and numbers to identify a specific production batch. Common examples of date codes are used by, expiration date, and best-before/sell-by.

Lot or date codes can be printed on primary packaging like yogurt cups or milk cartons or secondary packaging materials such as cartons containing multiple units of primary packaging.

Dairy industry coding and marking are important for several reasons. Expiration date coding, for example, serves as a guide for customers on product freshness and expiration. This benefit ties into the significance of regulatory compliance. Regulatory requirements ask that product packaging include necessary information, including disclosures of allergies. There is no point in producing products if they pose health risks to consumers.

Understanding the role of lot/date coding helps manufacturers ensure they select the right coding solution for their production lines.

Ice cream

Cheese (cup container)

We’re here to provide you with more details.

Reach out today!

Why Is Lot/Date Coding Dairy Products Critical?

Both lot coding and date coding are crucial for traceability and quality assurance in the production of dairy products.

During a recall, for example, lot coding can help identify the batch of affected products so that every product in the production run/batch can be isolated and investigated. The root cause of customer dissatisfaction can then be pursued.

Without the right printer for lot coding on dairy products, handling and correcting situations like recalls where traceability is critical becomes a challenge. Accurate date coding primarily provides information relating to food quality, helping consumers know when products have lost freshness or are no longer suitable for consumption.

Curious about our pricing?

Click here to find out more.

Common Coding and Marking Challenges in the Dairy Industry

Speed, accuracy, integration of coding systems, and visibility of prints on varying packaging surfaces are some challenges manufacturers face when coding and marking food packages.

Production lines must move quickly if manufacturers are to meet consumers' ever-increasing demands. Traditional printing solutions are notoriously slow. Their inability to keep up with modern production requirements leads to inefficiencies and, eventually, downtime.

This is where printers for dairy coding, such as continuous inkjet printers, come into the picture as a solution provider. CIJ printers offer high-speed printing capabilities, making them the preferred marking technology in many applications, including dairy production.

Apart from human operators programming the right lot codes or date information on a printer for accuracy of input, industrial printers must be able to print on varying packaging materials without smudges or prints erasing. Print information inaccuracies could lead to food allergies as a result of missing nutritional information. A handful of allergy cases with consumers is enough to precipitate massive product recalls or heavy regulatory fines, which can be very costly for the business.

Another challenge for dairy product manufacturing lines is finding a printing and coding system that can integrate with existing production lines and be adaptable. Adaptability is especially key because consumer tastes are changing, leading to the need for new packaging material sizes and substrates.

To avoid the costs associated with constantly switching printing systems or making costly production line changes, dairy companies require versatile printing solutions. Fortunately, KEYENCE offers a CIJ for the food and beverage industry. Our print solutions solve speed, accuracy, flexibility, and adaptability challenges manufacturers face in the dairy industry.

Discover more about this product.

Click here to book your demo.

How the KEYENCE MK-G Series CIJ Coder Can Enhance Quality and Traceability in the Dairy Industry

The MK-G Series Integrated Smart Assist Camera and Smart Program Changing feature helps prevent printing mistakes that often stem from user input during changeover. When printer settings are switched on, the corresponding vision system’s settings are also changed, enabling mistake-free inspections. This versatility and adaptability contribute immensely to quality product delivery into the market.

The stability of ink particles under extreme temperature and humidity conditions ensures consistent print quality. One way the MK-G Series combats temperature and humidity changes is with our Ink Particle Optimization (Break Point Monitor) which adjusts the break point of each droplet of ink as viscosity changes due to temperature fluctuations. By implementing this feature, we can ensure consistent, quality prints, in ever changing environments. Accurate and reliable printing also translates into effective product documentation and traceability for manufacturers.

Another reason the MK-G Series is the product of choice for many dairy manufacturers is due to the several functions that are automated and require a low input of skilled labor. Thanks to the MK Dock, the printer is self-diagnosing and troubleshooting which allows the unit to recover from errors and required cleaning quicker than other unit on the market.

Tool-free, one-touch part replacement paired with on-screen instructions allows operators without specialized knowledge the ability to complete troubleshooting and replacement of faulty parts that can cause production downtime.

To learn more about how the MK-G Series can help with dairy product packaging date coding lot coding, contact us today.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)