Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Why Long Throw Distance Is Crucial for High-Quality Box Printing

On paper, case coders are simple: get ink onto a box without smudges, streaks, or missed data. But real-world production lines are rarely that clean. Boxes vary in height, spacing isn’t perfect, and cardboard flaps aren’t always flat. The throw distance, the space between the printhead and the box, determines whether the job is completed cleanly or becomes a maintenance headache. Long throw isn’t just about giving operators more room to work. It’s about building margin into the system so that coding doesn’t fail when conditions aren’t ideal.

KEYENCE designed the CC-1000 Series with that reality in mind. With a 15 mm 0.6" throw distance, the system prints high-resolution marks on corrugated surfaces without needing perfectly staged cartons. That distance isn’t just for show. It’s a buffer against splashback, printhead protection, and a built-in margin for everyday disruptions.

Understanding Throw Distance in Case Coding

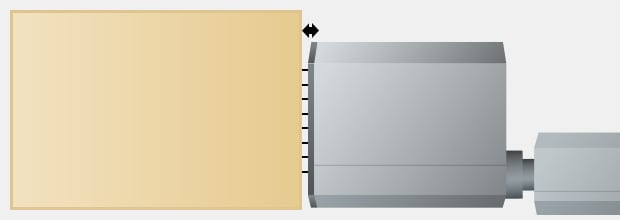

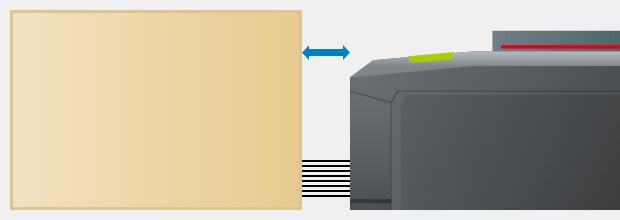

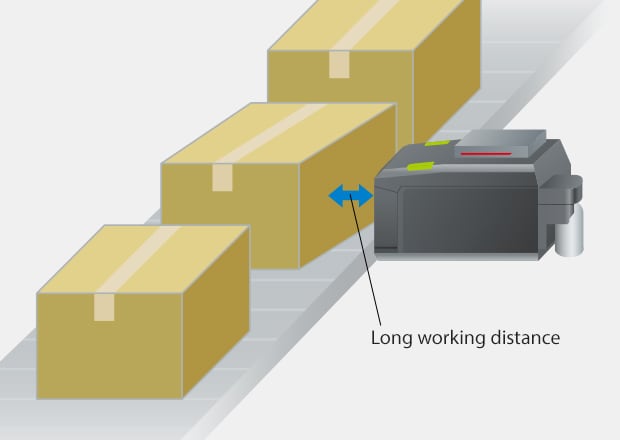

Throw distance directly affects how reliably a printer can place ink on moving targets. In terms of coding precision, reliability matters more than most realize. Typical high-resolution printers have to operate within 2-3 mm 0.08-0.12" of the box surface. That margin for error disappears the moment a box is slightly bowed, stacked unevenly, or shifts on the line. The longer the throw distance, the more real-world tolerance the system can absorb.

KEYENCE CC-1000 Series prints at distances up to 15 mm 0.6", roughly five times greater than conventional case coders. That extra spacing opens up installation options. It eliminates the need for custom brackets, rigid rails, or constant alignment. Because the printer can be mounted farther from the box face, it stays out of harm’s way during normal handling and palletization. That also means faster integration: lines can be retrofitted or reconfigured without tearing down and rebuilding every time the box dimensions change.

Conventional models (short working distance)

CC-1000 Series (long working distance)

We’re here to provide you with more details.

Reach out today!

Challenges with Short-Distance Printing

Blurred codes

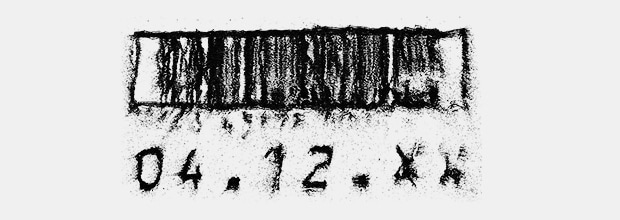

Short-throw distance demands a near-perfect production environment. Most coders built for close-up work assume every box runs with a true flat surface, consistent spacing, and no skew. In reality, even a few millimeters of variation can lead to blurred prints, missing data, or splattered ink.

Case coder splashback is one of the biggest issues with close-range systems. When ink strikes an uneven or glossy surface from too short a distance, it can ricochet back into the printhead. Over time, that builds up around the nozzle and leads to partial clogs. Ink mist inside the housing accelerates nozzle clogging and affects the consistency of every subsequent print.

There's also mechanical wear. Minor impacts from irregular box edges, even those too small to notice, can cause tiny shifts in printhead alignment. That shift compounds over time and introduces print drift, especially on wider characters or barcodes. The result? More downtime, more manual cleanings, and higher part replacement rates. Some facilities build entire cleaning schedules just to keep short-throw printers running reliably.

How Long Throw Distance Solves Splash Back and Head Collision Problems

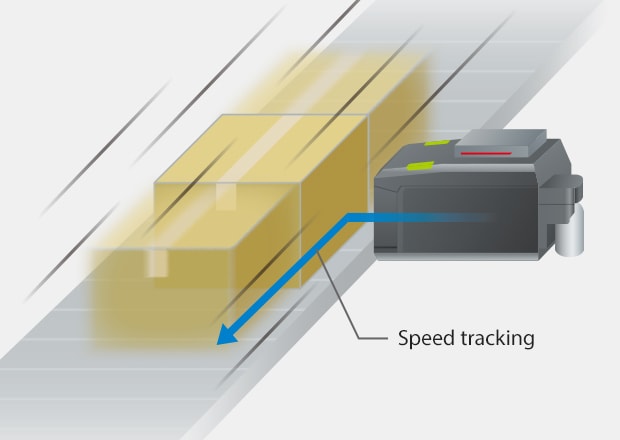

A longer throw solves both issues by design. Inkjet splashback becomes a non-factor when the ink has enough distance to land cleanly and the printhead is far enough back to avoid reflected mist. Print clarity stays consistent because the ink trajectory remains stable across the full throw range, even on non-flat boxes.

By putting more distance between the box and the hardware, collisions are less likely to occur. No more printhead crashes caused by bowed cartons or imperfect conveyor motion. This physical buffer extends the working life of the printhead and significantly reduces the need for emergency cleaning cycles or part swaps mid-shift.

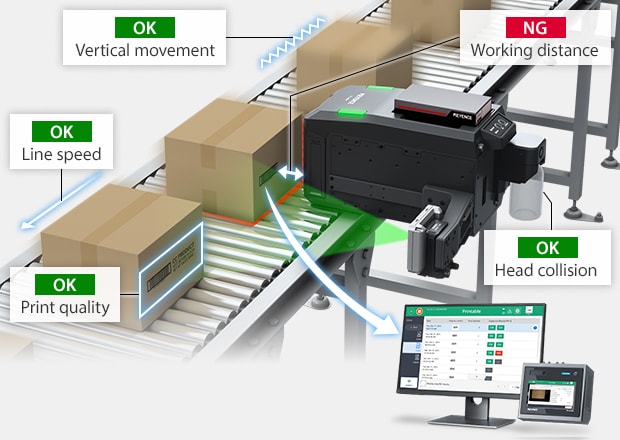

In the CC-1000 Series' case, that long-throw is paired with smart sensors that detect box position and adjust timing in real-time. That’s not just about printing cleaner, it’s about making the system resilient. Even as boxes fluctuate in height or alignment, print quality stays stable and consistent.

Curious about our pricing?

Click here to find out more.

Detecting Print Quality Degradation Early for Proactive Maintenance

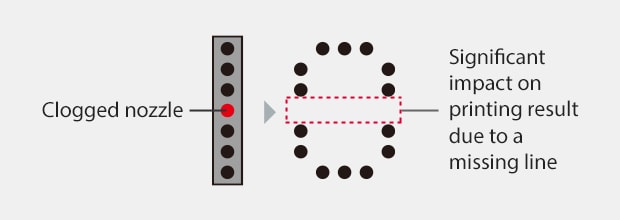

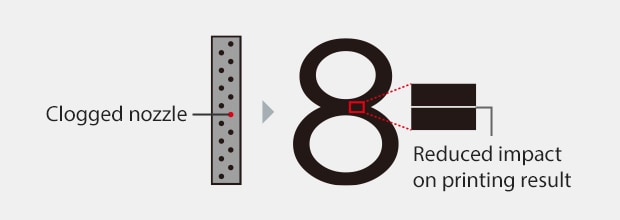

Ink placement matters just as much as distance. High DPI provides each character with sharper edges, higher contrast, and improved scannability, while also playing a role in fault tolerance. At 360 DPI, the CC-1000 prints using a larger number of nozzles than legacy 180 or 200 DPI systems. If a few nozzles clog, the remaining ones can still carry the load. Text stays legible, and barcodes stay scannable.

Conventional models (low-resolution)

CC-1000 Series (long working distance)

Older case coders don’t have that redundancy. A single clogged nozzle in a low-DPI printhead can create gaps, breaks, or smears, especially in alphanumeric codes or serialized data. On high-speed lines, those defects aren’t always caught before boxes move downstream.

More DPI also means more detail. This is particularly important when printing logos, QR codes, or product IDs that need to be machine-readable throughout logistics chains. Whether it’s scanned at a distribution center or verified during inventory, that extra sharpness cuts down read errors and returns.

Why Reliable Printing Means Less Waste and Greater Efficiency

Missed codes slow everything down and can require rework, inspection, and often repalletization. In some cases, they trigger regulatory non-compliance or customer chargebacks. Every bad print is a hidden cost.

Long-throw printing helps prevent those incidents before they occur. Fewer splashbacks mean cleaner heads, more consistent ink flow, and better long-term output. Reducing head contact means fewer alignment issues, less calibration drift, and fewer service calls.

Over time, that reliability compounds, resulting in less rework and fewer rejected boxes. No more holding pallets due to failed code inspections; downtime decreases, throughput increases, and operators focus on printing, not troubleshooting.

Operation status visualization

* Example using multi-sensor unit

For operations that run short production runs or frequently changeover, consistency matters more than speed. The CC-1000 Series' long-throw distance printing and nozzle redundancy provide that consistency, regardless of how often substrates, sizes, or layouts change.

Discover more about this product.

Click here to book your demo.

The Critical Role of Throw Distance in Industrial Box Printing

There’s no shortage of case coders that work well on paper. However, the throw distance separates the printers that survive in industrial settings from those that don’t. It’s what lets a coder stay stable during shift changes, SKU transitions, or packaging inconsistencies.

The KEYENCE CC-1000 Series doesn’t just offer more distance, it pairs that spacing with high-resolution output, smart detection, and self-compensating nozzle logic. That’s what allows it to run with fewer interruptions while still meeting the code quality demands of today’s supply chains.

For facilities coding thousands of boxes a day, across multiple substrates and setups, a longer throw isn’t a nice-to-have. It’s the only way to keep moving.

See how the CC-1000 Series reduces clogs and wear with long-throw printing, supports printhead protection and keeps your line running without interruption.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Causes Splashback in Box Printing?

Inkjet splashback occurs when ink is applied too close to the surface, particularly on uneven or coated boxes, causing droplets to bounce back into the printhead and potentially trigger clogs over time.

Does Throw Distance Affect Ink Quality?

While it doesn’t change the ink itself, longer throw distance helps maintain output consistency by minimizing mist, preventing buildup, and allowing ink to settle more cleanly on the substrate.

How Does DPI Factor Into Box Print Clarity?

DPI determines how precisely ink is placed; higher DPI translates to sharper edges, crisper barcodes, and greater resilience against minor nozzle clogs.

Is Long-Throw Distance Printing Compatible With All Box Sizes and Materials?

Yes, long-throw systems accommodate variations in box height, shape, and surface texture, making them especially useful on lines with frequent changeovers or less rigid packaging requirements.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper