Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

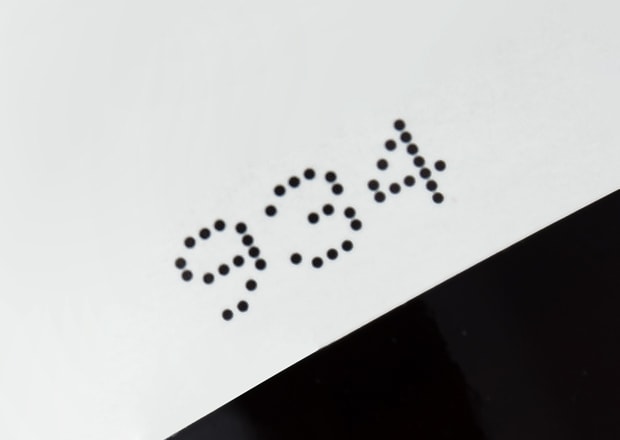

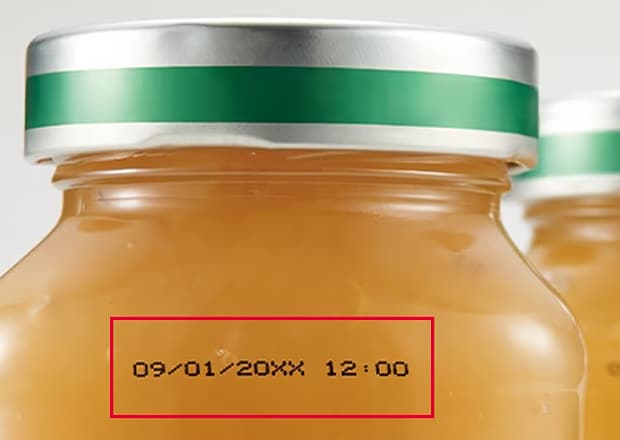

Date and Lot Codes Printing on Glass Bottles

Glass bottles of wine or jam are date coded while moving on a belt conveyor or in a bottle-filling machine. CIJs can print clear characters without flaws, even on curved surfaces. It is also possible to mount a CIJ on a labeler to print before labels are applied to bottles. Glass bottles are mostly used to store perishable goods and require legible expiration dates and lot codes. However, due to the properties of glass as a printing substrate, as well as the speed of the bottling line, printing on glass bottles comes with its own set of challenges.

Wine

Jam

Challenges in Printing on Glass Bottles

Glass is a hard and brittle material, mainly used for its strength and recyclability in the food and pharmaceutical industries and other industries that deal with perishable goods, such as cosmetics.

The biggest challenges when it comes to printing on glass are directly tied to the material properties of glass: mostly its non-absorbance and smooth surface. The fact that glass doesn’t absorb ink means the ink has to adhere to the surface of the substrate, which can be a problem due to the smooth surface.

However, if the ink has enough adhesion and dries quickly, it circumvents both problems.

We’re here to provide you with more details.

Reach out today!

Key Features for Glass Bottle Printing

As stated above, using an adequate glass bottle printer and ink is paramount for printing on glass. A good printer ensures that the printed text or barcode is legible, as it provides crucial information about the product’s expiration date and other information tied to logistics.

Print speed and precision are incredibly important; however, we mustn’t neglect the significance of ink, which has to be durable to withstand bottling operations, storage, transport, and use by the end user. And if the bottles are reusable, the ink must also be washable, on top of the aforementioned durability.

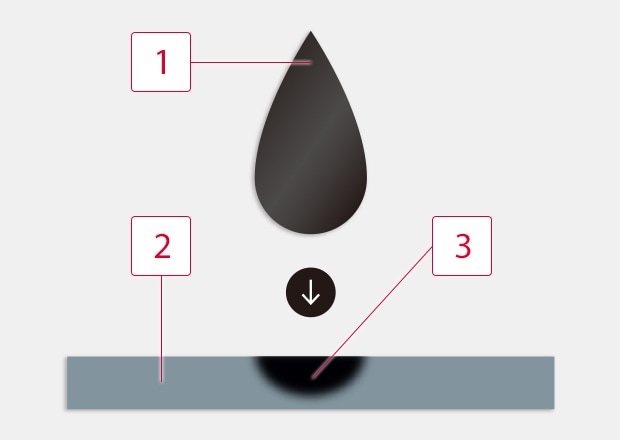

Properties of Dye Ink

- No precipitation when mixed with liquid

- Absorbed by print targets

- Short-term fade resistance

-

1Dye ink

-

2Target

-

3Dye ink sinks into targets easily

Glass Bottle Inkjet Coder Technology

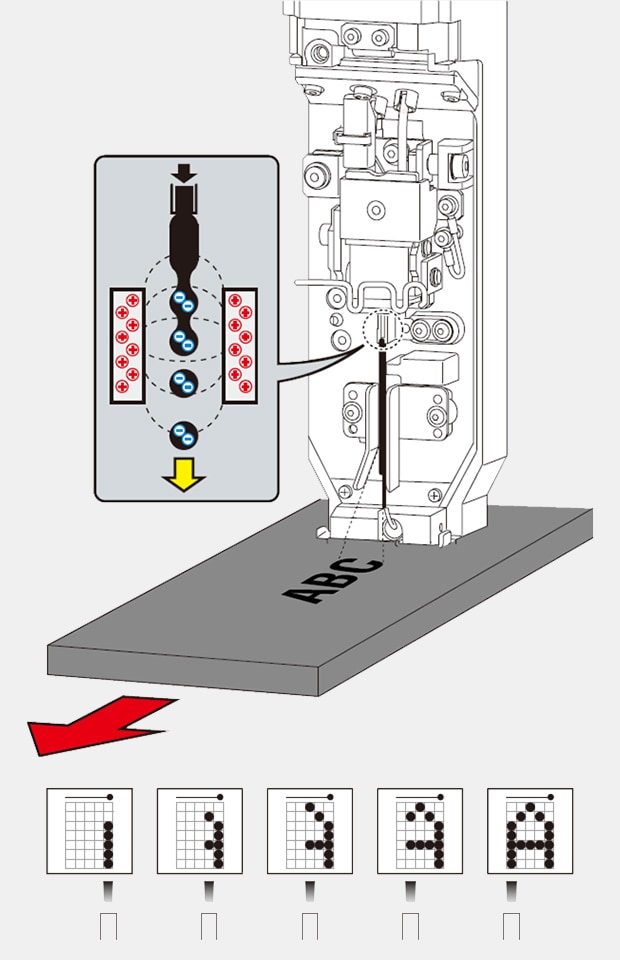

Printing on glass bottles is usually done using continuous inkjet printers, abbreviated as CIJs. CIJ printers rely on the continuous flow of ink that is pushed through a high-pressure nozzle inside the printhead.

The process breaks down the ink into small droplets, which are then electrostatically charged and deflected onto a substrate. The result is legible, and high-quality print that is achieved at great speeds, making CIJ printers perfect for glass bottle coding in bottling facilities.

- Step 1: Pressurized ink is supplied to the print head from the controller.

- Step 2: Ink is fed to the nozzle which has the piezoelectric oscillator and discharge hole.

- Step 3: The ink is discharged while being oscillated by the piezoelectric oscillator, and it is simultaneously given a negative electrostatic charge. The ink is formed into an ink column, but when saturated with the negative charge, the ink becomes particles, and those particles separate from the ink column.

- Step 4: The electrostatic detection sensor monitors the ink particles to ensure they receive the appropriate electrostatic charge to prevent malfunction.

- Step 5: The ink particles that discharge from the nozzle pass between two deflecting electrodes where an electrical field is generated by a voltage of around 7000 V. At this time, a bending force acts on the ink particles according to their electrostatic charge to change the direction they travel. Synchronously, the target or print head is moved perpendicular to the ink particle travel direction to print the desired content.

- Step 6: Ink not used for printing is collected in a pipe called the gutter and reused.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Glass Bottle Printing

What Are the Benefits of Continuous Inkjet (CIJ) Technology on Glass Bottles?

The benefits of using CIJ technology on glass bottles are legible, durable, and high-quality prints achieved at high speeds suitable for mass production.

Why Is Date/Lot/Serial Number Printing Crucial on Glass Bottles?

Date code printing on glass bottles, lot code printing on glass bottles, and serial coding all have different purposes. Date codes typically refer to the manufacturing and expiration date of a product for safety purposes. Lot codes are assigned to a group of products made together under similar conditions, which is crucial for quality control and traceability. Serial numbers are unique identifiers assigned to individual items.

Most Food, Drug, and cosmetics require a best by date by law. To take this a step further, KEYENCE is the only manufacturer that makes marking systems like CIJ and inspection equipment like presence absence and OCR cameras. This guarantees a nice lot code or best by date is on every product.

Why Choose Our CIJ Printers for Lot/Date Coding on Glass Bottles?

Not only is KEYENCE’s MK-G Series of CIJ printers precise, reliable, and fast, but it also eliminates all the guesswork that might be associated with maintenance due to self-troubleshooting features implemented in the product.

Have more questions about continuous inkjet technology? Learn more today.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper