Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Beverage Coding and Marking Machines

In beverage production, speed is constant. Every can or bottle leaving the filler must carry a durable, legible mark that withstands shipping and storage. From glass bottles to aluminum cans and paper cartons, beverage marking keeps every product traceable as it moves down the line. Continuous inkjet (CIJ) printers handle that work at full pace, combining fast printing with the durability that beverage environments demand.

Efficient Coding Solutions for the Beverage Industry

High-output beverage lines move fast, often thousands of bottles or cans per minute. CIJ printers apply codes without contact, keeping print quality steady even as line speeds or container shapes change. They mark glass, PET, aluminum, and cartons with equal precision.

Compact printheads fit tight spaces, integrate with conveyors, and move easily between lines. Because coding happens continuously, operators can run longer without interruptions while maintaining sharp, readable lot and date information. This reliability supports both small producers and large facilities operating around the clock.

We’re here to provide you with more details.

Reach out today!

Why Accurate Marking Is Essential in the Beverage Industry

Accurate date coding on beverages ties production to real-world timelines as a legible mark tells retailers when to rotate stock and gives shoppers quick confidence in what they’re buying. When each batch carries its own identifier, tracking it through distribution takes minutes instead of hours.

Strong beverage marking also reflects directly on brand quality. A faint or misplaced code can make an otherwise perfect product look careless, undermining consumer confidence For companies selling premium or craft drinks, clean, consistent marking protects both the packaging design and the trust that design builds.

Date Coding and Marking on Beverages

Bottles

Bottles come in various shapes, sizes, and materials to meet manufacturers' needs. Continuous inkjet printers provide precise printing to code and mark bottles accurately. CIJ printers ensure clear, readable codes, meeting industry standards.

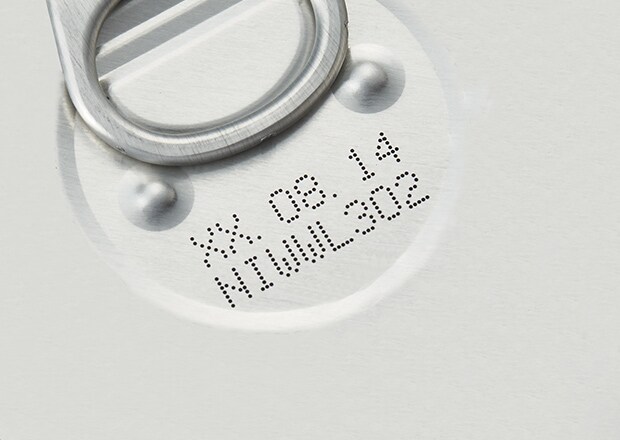

Printing example

Installation example

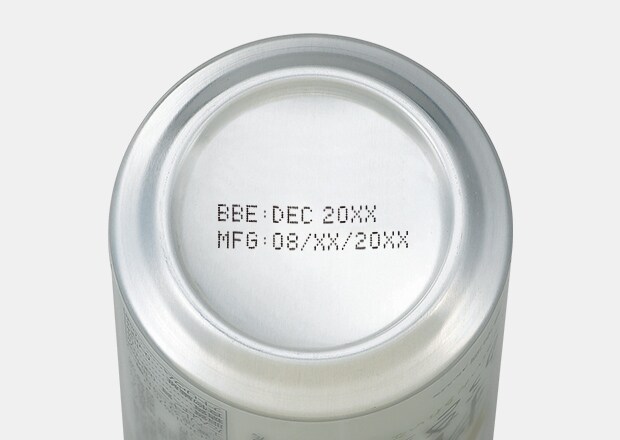

Cans

Cans are popular for beverages, especially carbonated drinks. Industrial inkjet printers ensure high-quality, legible codes on metal cans, even in harsh environments. One-touch nozzle replacement for immediate error recovery, minimizing downtime and ensuring efficient production.

Printing example

Installation example

Printing example

Installation example

Glass Bottles

Proper labeling on glass bottles is crucial. The MK-G Series' impact-resistant design can withstand any falls/impact during glass bottle marking. It also offers reliable, uninterrupted lot coding/date coding for clear/accurate labeling.

Printing example

Installation example

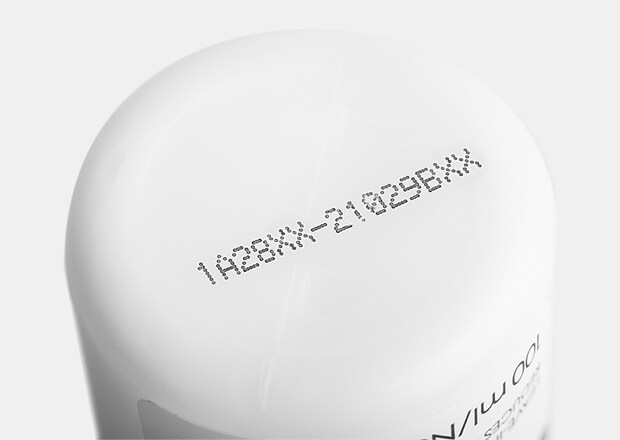

Hard Plastic Containers

Hard plastic containers are widely used in the beverage industry, making accurate beverage date coding essential. CIJ technology offers self-troubleshooting for quick issue resolution and easy maintenance/cleaning.

Printing example

Installation example

Curious about our pricing?

Click here to find out more.

Challenges in Beverage Marking

Beverage lines face unique challenges, including condensation, sugar dust, and high humidity. These factors, along with cold-fill operations and frequent washdowns, can cause smudging or adhesion loss on unprotected printers. Routine cleaning only adds to the stress, exposing equipment to water and chemicals.

CIJ printers built for beverage environments use sealed housings, stainless-steel frames, and automatic printhead cleaning. CIJ inks can struggle to mark damp surfaces, but our formulation maintains clear, legible codes even when bottles move directly from filling to packaging. These features sustain print stability at the speed beverage lines demand.

Why Choose KEYENCE CIJ Printers for Beverage Date Coding

KEYENCE CIJ printers are designed for continuous use in demanding beverage environments. Automatic maintenance and nozzle recovery reduce manual cleaning, keeping production steady during long runs. The system’s monitoring tools alert operators to performance changes before issues develop.

Ink options match nearly any beverage marking need. Our CIJ inks are engineered for versatility, delivering clear, durable codes on glass, PET, and other smooth materials. High-contrast formulations enhance readability on dark substrates, while washable options support returnable glass programs. Specialized formulations provide clear, permanent codes without affecting the package design or material appearance.

KEYENCE CIJ models sustain beverage-class speeds while producing clear, consistent characters. Their sealed printheads and corrosion-resistant construction stand up to washdowns and cold rooms, making them reliable where uptime and print clarity matter most.

Tailored Solutions for Beverage Marking Needs

No two beverage lines run under the same conditions. Temperature swings, container materials, and throughput all influence which bottle coding machine makes sense. For most operations, CIJ technology covers the widest ground (fast lines, mixed substrates, and flexible layouts) while laser systems provide lasting codes for premium or decorative packaging.

Case coders tie the process together by marking boxes and trays, closing the loop from product to pallet. Because beverage coding and marking setups differ, integration flexibility matters as much as speed. CIJ systems drop into existing conveyors and fillers with minimal changeover. Whether the facility bottles a few thousand units a day or runs several lines nonstop, these printers keep coding consistent and ensure production runs smoothly.

Start Improving Your Beverage Marking Today

Contact us for personalized beverage printing solutions.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Date Coding on Cans and Bottles in the Beverage Industry

What Are the Benefits of Implementing KEYENCE Date Coding CIJ Technology in the Beverage Industry?

The benefits include compliance with regulations, no compromise on accuracy for speed, traceability and product safety, and minimal maintenance requirements and downtime.

How Does KEYENCE's CIJ Technology Cater to the Specific High Demands of Coding on Cans and Bottles?

One main advantage is its ability to deliver fast, accurate beverage coding and marking without compromising print quality. The built-in diagnostics of KEYENCE CIJ systems ensure consistent performance and prevent beverage coding errors, minimizing downtime and reducing waste.

How Does CIJ Help Manufacturers Comply with Regulatory Requirements and Industry Standards for Date Coding on Beverages?

CIJ printers provide high-speed, reliable performance for printing batch numbers, expiry dates, and other crucial info. They ensure traceability in production, aiding quality control and compliance with safety regulations.

Can MK-G Series Coders Seamlessly Integrate into Existing Beverage Production Lines for Tracking and Traceability?

They are compact, easily adaptable, and simple to install in your production setup. Since MK-G Series coders require no skilled labor and less human interaction, resulting in less user error, they offer a cost-effective beverage coding and marking solution.

Why Is Date Coding on Cans and Bottles Critical for Product Traceability and Recall Management?

Beverage date coding enables manufacturers to consistently track products through the supply chain with high-quality codes and can swiftly identify affected batches during a recall.

Can KEYENCE Printers Handle High-Speed Beverage Production Lines?

Yes. KEYENCE CIJ printers match beverage line speeds while maintaining consistent code placement through integrated sensors.

How Do KEYENCE Printers Maintain Legibility on Beverage Packaging?

Our CIJ inks deliver consistent, legible codes in typical production environments, with automatic printhead cleaning that maintains mark quality and minimizes downtime, even in areas prone to temperature changes or light moisture.

Are KEYENCE Printers Suitable for Marking Both Plastic and Glass Bottles?

Yes. Our inks grip glass, and contrast inks stay clear on PET. The printhead adjusts easily to curved bottles, keeping bottle coding steady at full speed.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)