Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Efficient Pet Food & Animal Feed Packaging with Continuous Inkjet & Case Coder Solutions

Pet food and animal feed lines move at a steady pace, and packaging varies from flexible pouches to rigid cans and large corrugate cases. Clear codes support traceability, production timing, and distribution accuracy across every package style.

KEYENCE offers coding on pet food and animal feed packaging solutions with the MK-G Series continuous inkjet printers (CIJ). Perfect for high-speed production, it prints on various materials and has a self-cleaning function, minimizing downtime and maintenance costs.

Ensuring Compliance in Pet Food & Animal Feed Packaging with KEYENCE

Pet food and feed producers handle multiple regulations tied to safety, freshness, and ingredient visibility. A date and batch coding printer allows teams to apply the lot numbers, expiration dates, serial data, and other production details required for traceability. Packaging surfaces change across product families, and each one demands codes that stay readable through handling, storage, and transport. KEYENCE continuous inkjet platforms support a consistent print structure on films, foil, rigid containers, and coated materials.

We’re here to provide you with more details.

Reach out today!

High-Speed Inkjet Printers for Pet Food and Feed Production Lines

Modern feed operations run long hours, and production speed shapes every decision on the floor. An industrial inkjet printer keeps variable information aligned with that pace. Non-contact inkjet marking is well-suited for this environment because it forms characters while the target remains in motion.

Pouches, cans, chub packs, and bottles often travel on vibration-heavy conveyors, and stable droplet control keeps alphanumeric characters sharp as each product passes the print head. A continuous inkjet (CIJ) printer for animal feed production handles line variation, curved surfaces, and mixed materials without slowing upstream or downstream processes.

CIJ & Case Coders for Pet Food Packaging

Primary and secondary packaging call for different coding approaches. CIJ platforms place production data on flexible and rigid formats at high speed, while case coders, like the CC-1000 Series, take on the outer cases used for bulk shipments, wholesale distribution, and warehouse handling. Combining both in a single workflow simplifies the movement of information from the primary package to the carton. This supports both retail-level traceability and pallet-level visibility. CIJ systems carry most of the workload across pouches, cans, and bags, while the case coder focuses on box printing and large-character markings for corrugated and shrink-wrapped trays.

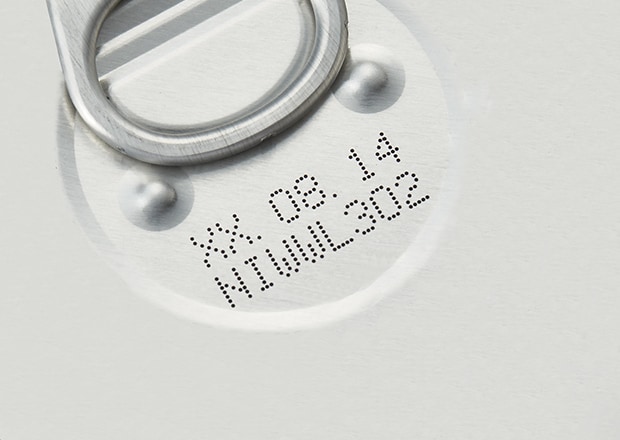

Metal Cans

Metal cans are popular for pet food packaging due to their durability. With an intuitive interface and automated self-maintenance, ensure high-quality, consistent markings at high speeds with the MK-G-Series.

Printing example

Installation example

Paper Bags

The MK-G Series simplifies the paper bag coding process, requiring no technical skills for operation or maintenance, reducing downtime and costs by eliminating service contracts. Recovery is easy with simple guidance or automated troubleshooting.

Printing example

Installation example

Chub Packs

Chub packs are flexible, cylindrical bags. The unit uses non-contact printing and adaptive settings to ensure high-quality coding on pet food and animal feed packaging surfaces, including curved or uneven packs.

Printing example

Installation example

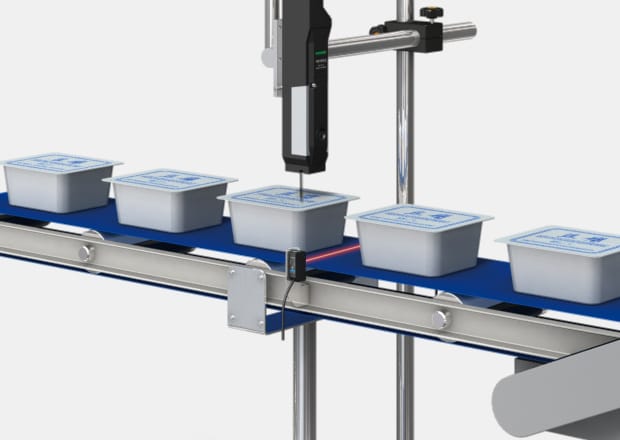

Rigid Plastic Bottles and Cups

Installing an inkjet printer on a conveyor belt enables companies to mark hundreds of plastic bottles and cups per minute. Parallel-filled products can be marked by traversing the inkjet print head.

Printing example

Installation example

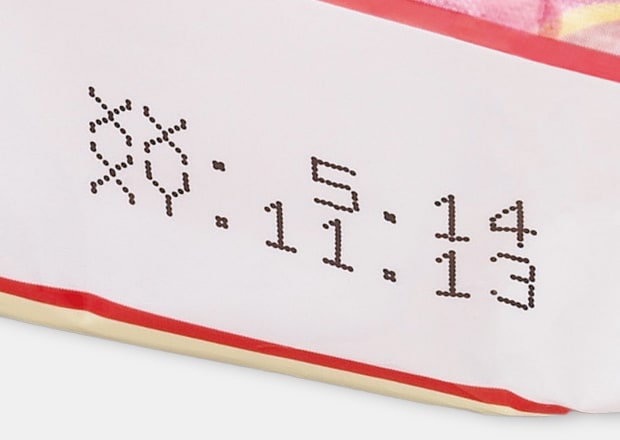

Flexible Plastic and Foil Bags and Pouches

Our CIJ offers variable data printing, marking accurate expiration dates and batch numbers on each package. This saves time and reduces human error by eliminating manual labeling of individual containers of varying shapes.

Printing example

Installation example

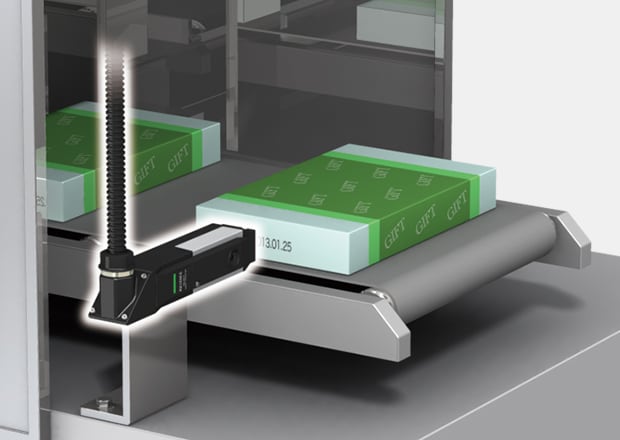

Cartons

The MK-G Series offers reliability with high-speed and durable carton printing, sensing ink particles 10 times per second to ensure high-quality print in changing conditions.

Printing example

Installation example

Curious about our pricing?

Click here to find out more.

Challenges in Coding and Marking on Pet Food and Animal Feed Packaging

Variable Packaging Surfaces

Each surface, like plastic bags or metal cans, requires a unique coding approach. The MK-G Series has a conditioning tank system that collects solvent after cleaning, which helps maintain stable print quality.

Production Environments

A major pain point in production is frequent maintenance. The MK-G features self-diagnostic routines and auto-cleaning, saving technicians time and ensuring consistent coding on pet food and animal feed packaging.

High-Speed Production

With rising consumer demand, manufacturers seek to optimize production. Our industrial inkjet printers provide performance analytics, monitoring hourly operation status, including error counts, operating hours, temperature, and viscosity for up to 100 days.

Coding Compliance Requirements

Maintaining legibility on codes to ensure compliance is vital. Our MK-G Series automatically senses and adjusts ink particles, ensuring clear codes even in varying production environments.

Discover more about this product.

Click here to book your demo.

The Role of Inkjet Printers in Maintaining Freshness and Traceability

Clear production and expiration data support product freshness, guide rotation, and keep ingredient tracking aligned across every stage of movement. A stable inkjet coding system places this information on substrates that face varied conditions, including heat from retort processes, cold storage, or abrasion during transport. Non-contact inkjet marking keeps character formation consistent, allowing the printed data to remain visible through each stage of the packaging and shipping process.

How KEYENCE Inkjet Printers Improve Operational Efficiency in Feed Production

A reliable industrial inkjet printer reduces operator tasks and supports high uptime across long production windows. Automated cleaning routines and built-in ink stability checks lessen the amount of hands-on attention a CIJ printer needs. This helps teams maintain print quality during extended runs or environmental variation. A CIJ printer for animal feed production supports these conditions with controlled ink behavior and a sealed print head design to reduce downtime and increase production flow.

Box Printing Case Coding

Secondary packaging in pet food and animal feed often includes bulk corrugate cases and large shipping cartons. Box printing keeps these containers aligned with lot and batch data used upstream on primary packaging. A case coder places clear, high-resolution characters on corrugate so warehouse teams can scan and sort feed products quickly.

Get in touch to learn about our CIJ & case coder solutions for pet food packaging.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Date Coding in the Pet Food and Animal Feed Industry

What Is the Importance of KEYENCE Inkjet Printers in Helping with Pet Food Packaging Traceability?

Lot, date, and batch coding on pet food and animal feed packaging is essential for product traceability, expiration date tracking, and regulatory compliance in the pet food and animal feed industry.

What Are the Key Factors to Consider When Selecting a Date-Coding Solution for Pet Food and Animal Feed Packaging?

Key factors to consider include the speed and ease of maintenance, packaging materials, production line speed/throughput, and ease of integration into production lines.

Can the MK-G Series Accommodate the Diverse Packaging Materials Used in the Pet Food and Animal Feed Industry?

Yes, the MK-G Series can accommodate various packaging materials like pouches, paper sacks, and metal cans, and integrates seamlessly into existing lines.

How Does KEYENCE CIJ Technology Reduce Cost and Downtime in Pet Food and Animal Feed Packaging Date Coding Operations?

Our MK-G Series printers have an IP55-rated head and controller for dust and water resistance, ensuring reliable operation in dirty and wet environments, and reducing cost and downtime.

How Does the MK-G Series Support Compliance with Pet Food and Animal Feed Packaging Coding and Marking Industry Regulations?

The CIJ ensures compliance with regulations by providing accurate, legible coding for consumer safety and traceability. It prints high-quality codes at high speeds that marketing will love.

What Are the Benefits of Non-Contact Inkjet Marking for Pet Food Packaging?

Non-contact inkjet marking forms high-quality characters while the product stays in motion, maintaining readable codes on curved, uneven, or vibration-prone surfaces like pouches, chub packs, bottles, and bags.

What Is the Benefit of Using a Case Coder for Pet Food Carton Labeling?

Case coders support box printing on corrugate and provide large, scan-ready markings for shipping, palletizing, and warehouse handling.

Can CIJ and Case Coder Systems Work Together in Pet Food Operations?

Yes. CIJ handles primary packaging, while the case coder applies secondary codes on cases. Together, they keep product, case, and pallet information aligned across the entire workflow.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper