Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Coding on Plastic Parts in Modern Manufacturing

Coding on plastic parts ensures traceability, authentication, and quality control, but traditional methods, such as stamping and laser engraving, often come with hidden maintenance costs, downtime, and smudging. However, inkjet technology has transformed the process, making coding on plastic parts more efficient and cost-effective.

The KEYENCE MK-G Series stands out as the world’s first continuous inkjet printer with self-troubleshooting capabilities, eliminating complex maintenance requirements. With advanced sensor technology, it performs autonomous maintenance, reducing downtime and streamlining operations for manufacturers.

Challenges in Coding and Marking on Plastic Parts

Coding and marking on plastic parts are essential in industrial manufacturing, particularly in packaging, automotive, aerospace, and electronics. However, factors such as high temperatures, ink consistency, and production conditions present unique challenges in marking plastic surfaces.

- Temperature-Related Printing Challenges: High-temperature manufacturing environments can make it difficult for traditional inkjet printers to ensure proper ink adhesions, causing smudged or illegible codes and traceability issues.

- Ink Clogging Issues: Pigmented ink provides sharp, high-contrast markings on plastics but is prone to clogging printer nozzles, causing print inconsistencies and downtime.

- Device Vibrations: Vibrations in plastic manufacturing can disrupt printing accuracy and consistency, leading to misaligned or unreadable codes on plastic surfaces, a common issue with traditional printers.

We’re here to provide you with more details.

Reach out today!

Why Choose the MK-G Series CIJ for Plastic Parts Coding

The MK-G Series continuous inkjet printer addresses these challenges by delivering high-quality, uninterrupted lot coding through advanced self-monitoring technology and automation.

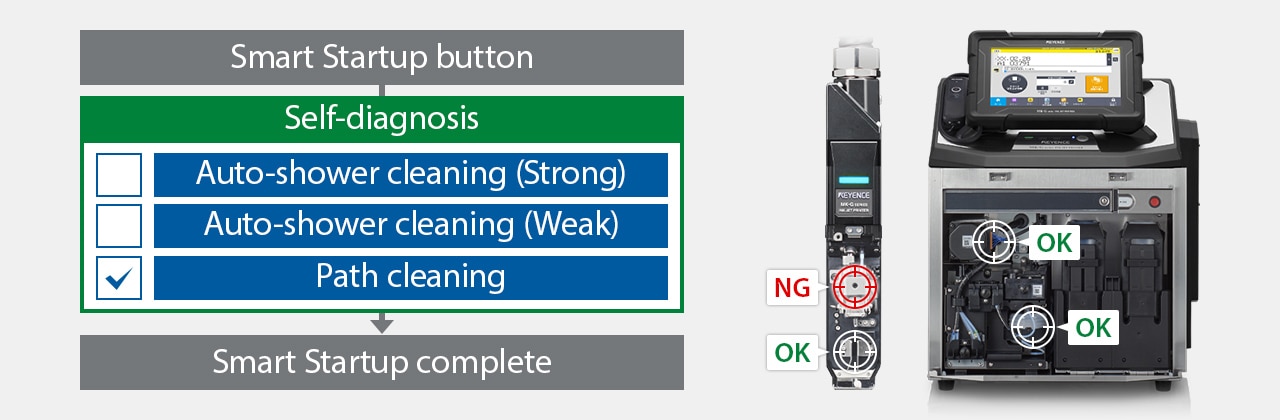

Self-Troubleshooting Capabilities

The MK-G Series CIJ automatically detects and resolves issues, eliminating the need for complex manual maintenance. Its self-cleaning system prevents clogs, ensuring consistent printing, reducing downtime, and boosting productivity.

Using the MK Dock enables self-diagnosis and cleaning to ensure stable startup.

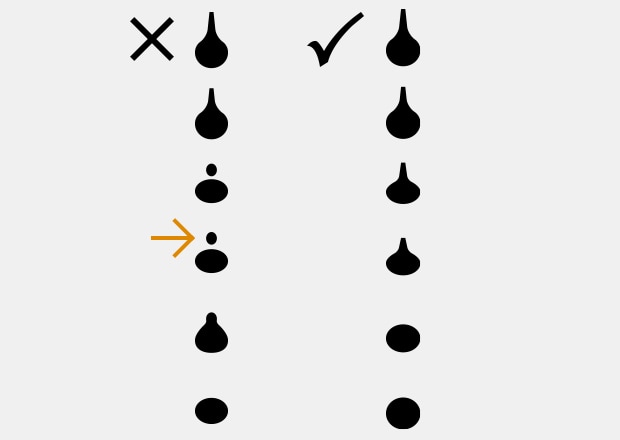

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

Ink Sensing for Extreme Conditions

The printer monitors ink particles 10 times per second, ensuring proper adhesion even in extreme temperatures, guaranteeing high-quality, reliable printing, and avoiding disruptions.

Less-than-optimal state of particles

Optimal particle state

Smart Startup and Sleep Mode

These features reduce the risk of clogs and maintain high-quality prints by automatically managing the printer's activity, minimizing downtime during production.

Durable Solvent-Based Ink

The ink is specially designed for plastic materials, offering resistance to chemicals, extreme temperatures, and tough conditions, ensuring reliable codes that last.

Precision on Various Surfaces

The MK-G Series can print on curved, uneven, or smooth plastic surfaces, making it adaptable for a wide range of lot coding applications.

Intuitive Touch Panel

An intuitive interface simplifies setup and operation, allowing for hassle-free lot coding and minimizing operator errors.

Compact, Space-Saving Design

Optimized for production lines with limited space, offering high-performance printing in a small footprint.

Versatile Customization

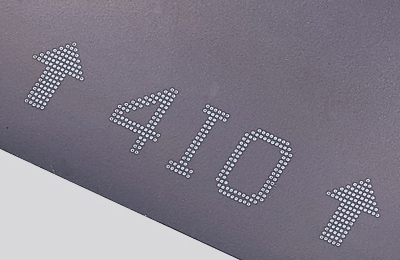

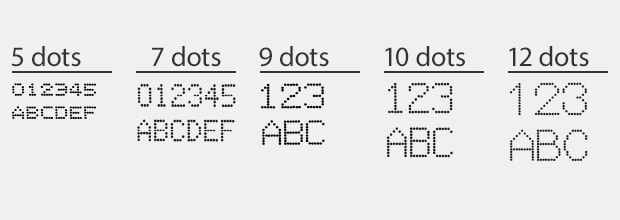

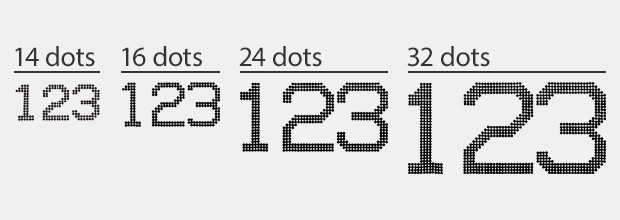

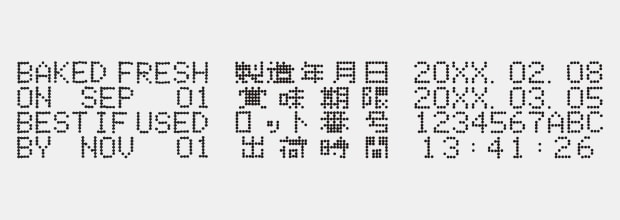

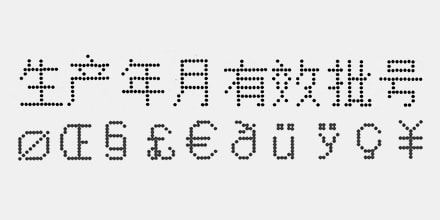

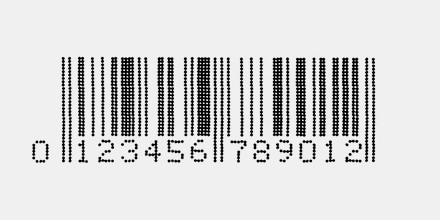

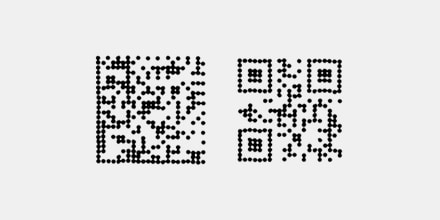

Supports adjustable print height, font sizes, styles, and barcodes, ensuring precise branding and compliance with regulatory standards.

5-12 dots

14-32 dots

Four-line printing

Logotypes

Unique-character languages

Barcode

2D codes

Streamline production with the MK-G Series CIJ printer. Contact us to learn more!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Coding on Plastic Parts

How Does Coding and Marking on Plastic Parts Improve Traceability and Compliance in Automotive Manufacturing?

Coding on plastic parts acts as a unique identifier for each component. This coding on automotive and aerospace parts allows for efficient tracking, tracing, and quality control throughout the supply chain while ensuring industry standards are met.

How Does the MK-G Series Printer Ensure High-Quality Coding on Uneven Plastic Surfaces?

The MK-G Series uses advanced CIJ technology for efficient, non-contact printing on plastic components. Its micro-nozzle ensures precise, high-quality prints, perfect for small characters and 2D codes, even on uneven surfaces.

How Does the MK-G Series Printer Simplify CIJ Maintenance to Improve Efficiency and Reduce Downtime in Coding Plastic Parts?

The MK-G Series printer boosts efficiency and reduces downtime with its automatic cleaning function. Whenever the printer shuts down—intentionally or due to a power outage—it runs a cleaning cycle. This eliminates the need for manual cleaning, prevents clogs, and ensures smooth operation.

How Does the MK-G CIJ Printer Support Consistent Code Printing on Plastic Parts Under Varying Temperature and Humidity Conditions?

The MK-G Series CIJ printer performs reliably in diverse conditions with an IP55 rating for dust and water protection, which is ideal for manufacturing environments with varying temperatures and humidity. Its advanced sensor technology ensures precise, consistent code printing on plastic parts, even in fluctuating conditions.

How Does the MK-G Series Handle High-Speed Production Lines Without Compromising Print Quality on Plastic Parts?

The MK-G Series delivers high-speed production, printing up to 2,525 characters per second. Advanced CIJ technology ensures precise, consistent marking at rapid speeds without sacrificing quality or clarity.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)