Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Coding on Rubber Products

Rubber products like pipes and hoses, produced through extrusion molding, require durable, high-contrast markings for identification and traceability. However, the flexible nature of rubber and the continuous production processes make achieving precise, long-lasting codes challenging. Traditional stamping methods often result in smudging or incomplete prints, compromising readability. In demanding environments where safety and performance are critical, lot coding helps manufacturers track production history and address defects quickly.

The MK-G Series continuous inkjet printer improves this process with self-diagnostic functions that ensure accurate, uninterrupted coding while minimizing errors. Its remote control capabilities allow operators to manage multiple printers from a PC or smartphone, optimizing efficiency.

Common Challenges in Coding and Marking on Rubber Products

A key challenge in lot coding on rubber products is achieving clear, legible prints, especially with pigmented inks. While effective for marking on dark surfaces, these inks can clog nozzles, causing production delays, errors, and higher costs. Other challenges for rubber products include:

- Dusty and Hot Environments: Dust particles and high temperatures can compromise the quality and durability of printed codes, leading to smudging or fading.

- Coding Integrity: Its non-porous nature and low surface energy often cause poor ink adhesion and coding errors.

- Integration with Production Line: Frequent manual adjustments and equipment maintenance often cause costly downtime, disrupting efficiency and delivery schedules.

- Constant Reliability: The manufacturing process can be lengthy and can take days or weeks. Traditional contact-based stamping methods often fail during this time due to quick stamp wear, leading to higher costs and inconsistent marking quality.

We’re here to provide you with more details.

Reach out today!

Why Choose the MK-G Series for Coding and Marking on Rubber Products

The MK-G Series CIJ printers offer a solution tailored to the rubber industry. Using advanced non-contact printing technology, these printers deliver reliable, high-quality markings without smudging, even during long production runs.

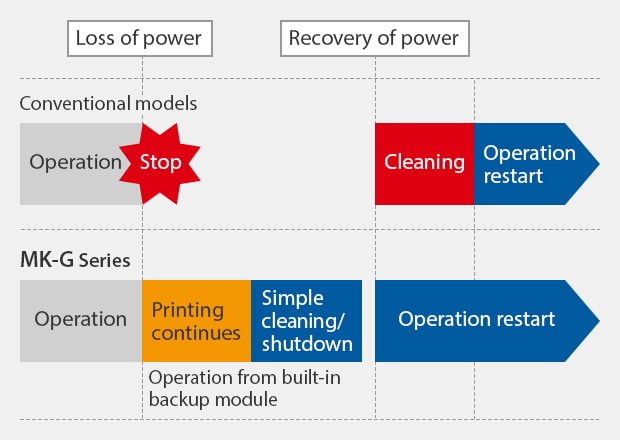

Advanced Internal-Path Cleaning System

Cleans the printer before every shutdown, even during power outages.

Consistent Print Quality

Ensures high-quality prints with minimal downtime or interruptions.

Prevents Nozzle Clogs

Reduces the risk of ink blockages, maintaining a smooth operation.

Uninterrupted Production

Supports continuous, reliable production with minimal maintenance.

Durability in Harsh Environments

IP55-rated head and controller can withstand dust, moisture, and heat. It also features an advanced automatic adjustment system that monitors environmental conditions and optimizes settings to maintain sharp, clear codes.

Optimized Ink Adhesion

Advanced ink adhesion technology and specially formulated pigmented inks deliver durable, high-visibility codes resistant to abrasion, chemicals, and extreme temperatures, ensuring seamless identification on rubber.

Seamless Integration

Fits effortlessly into any production line without downtime or extensive training, ensuring a smooth process from coding to delivery.

Non-Contact Printing

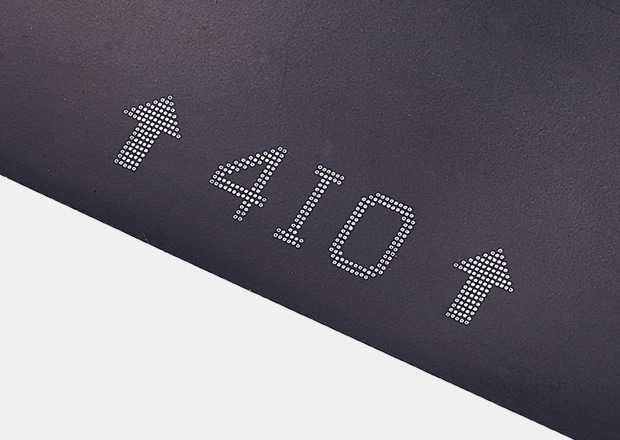

Applies ink directly to rubber surfaces for precise, high-quality markings without smudging or fading.

The MK-G Series CIJ offers a top-notch solution for efficient lot coding, especially on automotive and aerospace parts. To learn more about how these printers can enhance your operations, contact us today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Inkjet Coding on Rubber Products

How Does the MK-G Series CIJ Printer Ensure Precise Coding on Rubber Products in High-Volume Production?

The MK-G Series CIJ for the industrial industry monitors ink particles 10 times per second, automatically adjusting for optimal printing. Even in high-volume production with varying conditions like temperature and ink viscosity, the MK-G ensures precise, consistent coding on rubber products.

Why Is Date Coding on Tires Important for Compliance and Safety in the Automotive Industry?

Accurate date coding is crucial for vehicle safety. Over time, tires degrade due to heat and humidity, which can impact performance and increase safety risks. Clearly marked production dates help consumers track tire age and replace them on time, reducing road hazards.

How Does the Auto-Shower Cleaning Feature Benefit Inkjet Coding on Rubber Parts?

This feature is perfect for inkjet coding on rubber components, preventing pigmented ink clogs and ensuring consistent, high-quality results. It addresses common issues like disrupted flow and nozzle blockages, ensuring smooth operation and reliable performance.

How Does the MK-G Series CIJ Ensure Durable and Legible Markings on Rubber Products?

Faded markings on rubber products often result from nozzle blockages or ink viscosity changes. The MK-G Series solves this with advanced automation and KEYENCE sensor technology. It monitors ink flow, automatically cleans blocked nozzles, and adjusts for viscosity changes, ensuring clear and consistent markings.

How Does Lot Coding on Rubber Products Enhance Traceability and Product Integrity?

Lot coding on rubber products helps manufacturers track and trace items throughout the supply chain. It improves inventory management and allows quick identification and recall of defective or contaminated products. In a recall, detailed lot records help isolate affected items, saving time, cutting costs, and minimizing market disruptions.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper

![MK-U6000 Collection of Inkjet Printer Introduction Examples [Automobile industry Edition]](/img/asset/AS_74789_L.jpg)