Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Coding on Batteries and Other Curved Surfaces

As demand for high-performance batteries grows, manufacturers need precise, durable, and efficient marking solutions that keep pace with high-speed production lines and evolving industry standards. However, curved surfaces, small marking areas, and material compatibility create significant challenges for lot coding, traceability, and compliance.

The KEYENCE MK-G Series revolutionizes manufacturing by solving common issues like smudged codes and reliance on skilled operators. With cutting-edge features, it sets a new standard for precision and efficiency, streamlining operations and delivering superior results.

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking on Batteries

The battery industry faces unique challenges in coding and marking products like lithium-ion and lead-acid batteries and even coding on automotive and aerospace parts. Batteries need clear and consistent lot codes to ensure traceability and compliance.

- Coding on Curved Surfaces: Most batteries have cylindrical or round shapes, making it difficult for traditional battery date coding and marking methods to achieve clear and legible codes.

- Printing on Small Areas: Battery components have limited surface space, making it challenging to print high-contrast, micro-precision codes.

- Keeping up with Rapid Manufacturing Pace: The rapid growth of the battery industry has led to shorter production cycles, higher throughput, and more frequent product changes, making traditional methods like manual labeling or stamping outdated.

Why Choose the KEYENCE MK-G Series CIJ Printer to Enhance Battery Coding Efficiency

The MK-G Series CIJ for industrial manufacturing offers an advanced solution for lot coding on batteries and other curved surfaces with state-of-the-art non-contact marking technology designed to produce sharp, long-lasting codes while maintaining the speed required for fast-moving production lines.

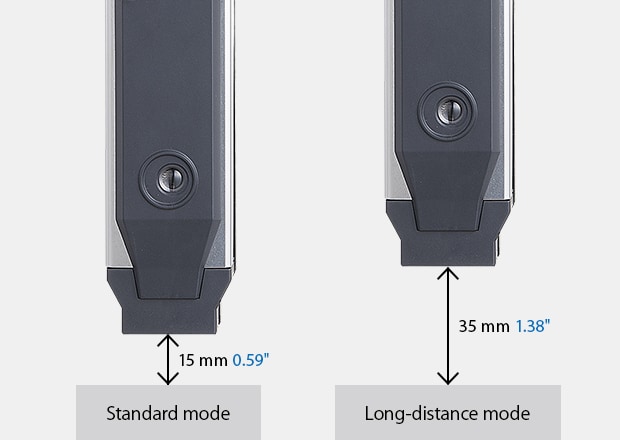

Long-Distance Mode for Curved Surfaces

The MK-G Series continuous inkjet printer allows the print head to be positioned up to 35 mm 1.38″ from the target, accommodating surface curvature and minimizing print inconsistencies.

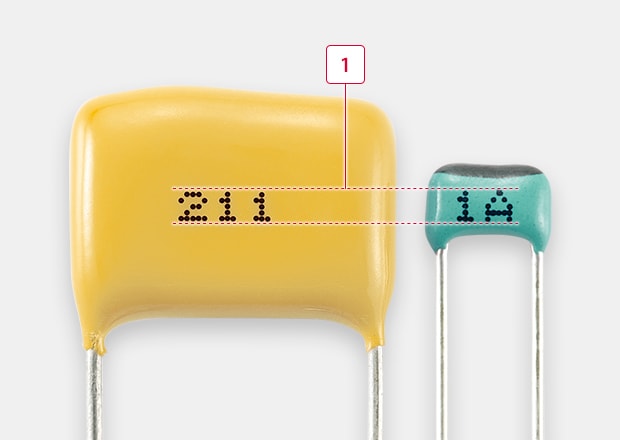

Advanced Micro Nozzle for Small Surface Printing

Designed for high-precision marking, the MK-G Series delivers sharp, legible 2D barcodes and small-character printing on compact battery components, ensuring reliable tracking and traceability.

-

1Character height 0.6 mm 0.02"

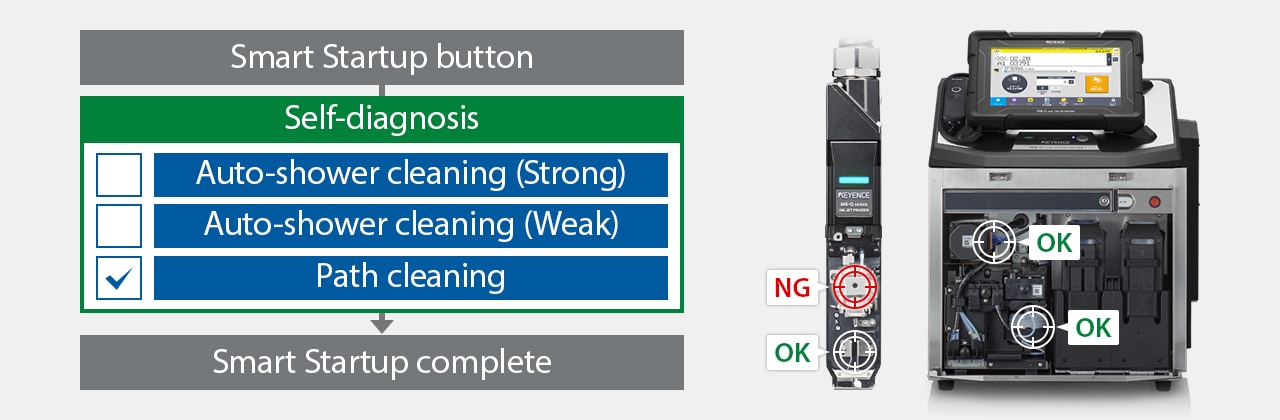

Self-Troubleshooting and Automated Maintenance

The MK-G Series CIJ self-diagnoses and performs automatic maintenance, eliminating the need for specialized operator expertise and reducing costly downtime.

Non-Contact Printing for Delicate Surfaces

Produces clear, high-quality prints while protecting sensitive materials, making it ideal for curved batteries.

Preserves Protective Coatings on Batteries

Unlike laser marking, inkjet printing prevents damage to corrosion-resistant coatings, ensuring optimal battery performance and compliance with industry standards.

Upgrade your battery coding process with the KEYENCE MK-G Series. Contact us today to learn more!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Marking and Coding on Batteries and Other Curved Surfaces

What Role Does Lot Coding on Batteries and Other Curved Surfaces Play in Regulatory Compliance and Product Recalls?

Lot coding on batteries and curved surfaces is essential for regulatory compliance and preventing product recalls. It ensures traceability in industries like pharmaceuticals, medical devices, and electronics, where strict adherence to safety standards is mandatory. Lot codes help manufacturers to quickly identify quality or safety issues, minimizing any potential harm to consumers and maintaining compliance with regulatory requirements.

How Does the KEYENCE MK-G Series CIJ Improve Production Efficiency for Coding on Curved and Irregular Surfaces?

The MK-G Series self-diagnostic system identifies and resolves issues, decreasing the need for manual maintenance. With features like automated troubleshooting and ink management, the printer maintains high-speed operation without interruptions from clogs or ink inconsistencies. Its advanced ink circulation system minimizes waste while preserving print quality, making it a cost-effective choice for high-volume manufacturing. By eliminating manual interventions and streamlining operations, the MK-G Series enhances throughput, lowers error rates, and delivers reliable, high-quality coding on curved and irregular surfaces.

How Does the MK-G Series CIJ Ensure Durable and Legible Markings on Batteries and Light Bulbs?

The MK-G Series produces high-resolution codes on smooth, reflective, or small-diameter objects, ensuring traceability and compliance. Additionally, the MK-G Series supports high-adhesion, heat-resistant ink formulations that endure high temperatures and environmental exposure, guaranteeing smudge-free markings on light bulbs and battery casings.

How Do the MK-G Series CIJ’s Advanced Features Support Efficient Battery Date Coding in High-Volume Production Environments?

The MK-G Series delivers high-speed coding on batteries and other curved surfaces at up to 1,827 characters per second, ideal for high-volume production. It ensures precise marking with clear codes and features automatic cleaning before shutdown to stay ready for every shift, even after power interruptions.

What Battery Materials Can the KEYENCE MK-G Series CIJ Printer Mark, and How Does It Handle Material Compatibility Challenges?

The KEYENCE MK-G Series CIJ printer offers precise, reliable marking on materials like metal, plastic, glass, and coated surfaces. With versatile inks and advanced technology, it ensures durable, high-contrast markings with excellent adhesion, even on irregular surfaces.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper