Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Choosing the Best Technologies for Flexible Packaging Coding and Marking

Flexible packaging is popular for its versatility and cost-effectiveness, making it a popular choice across various industries. In a market with countless consumer options, product differentiation becomes crucial for businesses. Coding and marking are essential in this process, ensuring regulatory compliance and product traceability.

With a wide range of coding and marking technologies available, selecting the most suitable coding and marking solutions for flexible packaging can be a challenge. Let's explore the top flexible packaging coding and marking technologies currently on the market.

The Importance of Flexible Packaging Coding and Marking

Each industry has unique flexible packaging coding and marking requirements, from the food and beverage industry to pharmaceuticals and cosmetics:

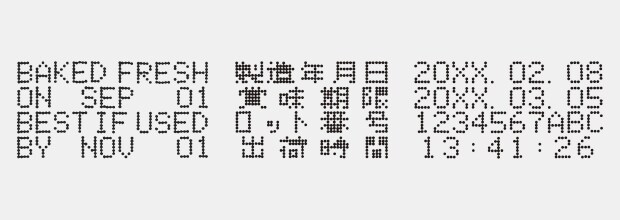

- Food industry: Accurate product identification is essential for safety and quality. Flexible packaging coding provides essential information like expiration dates and lot numbers, aiding traceability and enabling quick recalls when necessary.

- Pharmaceutical industry: Flexible packaging coding and marking are vital for regulatory compliance. Accurate labeling is essential for patient safety, as errors can have severe consequences.

- Cosmetics: Flexible packaging coding offers design versatility and cost-efficiency. In addition to meeting compliance standards, coding and marking help enhance brand image, making products stand out in a competitive market.

- Supply chain management: Reliable coding ensures easy product tracking, leading to efficient inventory management and reduced waste.

We’re here to provide you with more details.

Reach out today!

Comparison: CIJ vs. UV Laser Coders for Flexible Packaging Coding

CIJs use a continuous stream of ink droplets to create characters on the surface of the packaging material. An electrode electrically charges these droplets as they pass through a nozzle, creating a visible mark.

Alternatively, UV laser coders use a high-powered laser to mark the packaging material by altering its pigment layer. This process results in permanent, high-contrast codes.

Below is a closer look at these two technologies:

Continuous inkjet printers

Laser coders

Print Quality

UV laser coding produces high-quality, crisp, permanent marks that are resistant to fading and damage. The UV laser light induces a chemical reaction in commonly used plastic compounds that changes the color of the material. This creates contrast without damaging or removing any materials, creating permanent, high-quality codes.

Character size: 3 × 2 mm 0.12" × 0.08"

No. of characters: 10 characters

Marking pitch: 150 mm 5.91" spacing

| Line speed | Marking volume | |

|---|---|---|

|

UV laser coder

|

Line speed

150 meters 492.1'/minute

|

Marking volume

1000 items/minute

|

*Results will vary according to marking conditions and material.

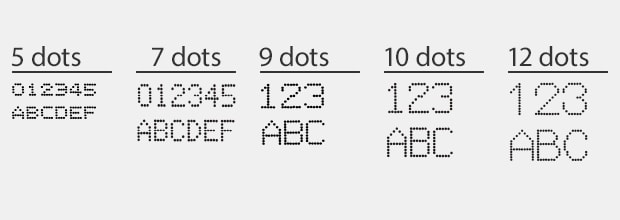

The MK-G Series CIJ prints reliable basic characters for dates or lot codes quickly, but may not offer the same level of precision and detail as laser coders. Ultimately, the choice between these two technologies will depend on the specific coding requirements of the production line.

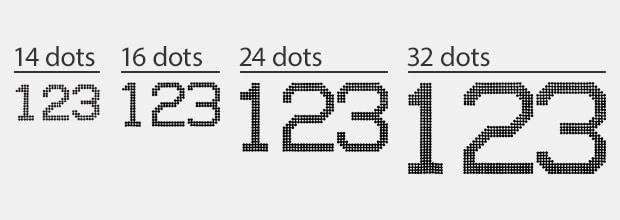

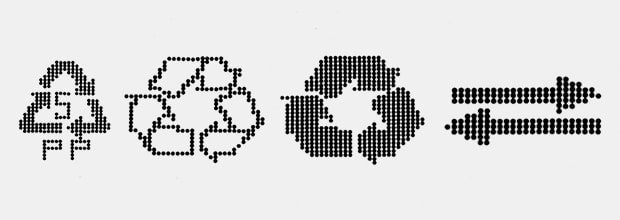

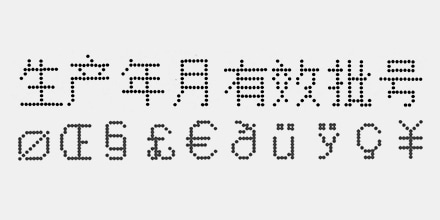

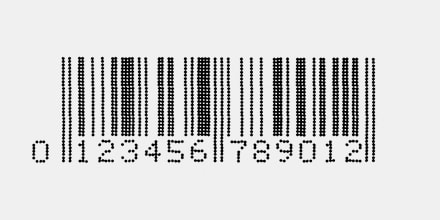

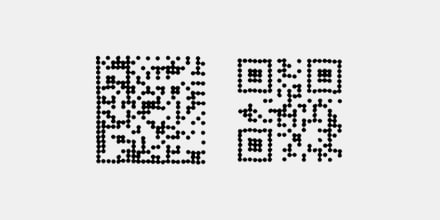

5-12 dots

14-32 dots

Four-line printing

Logotypes

Unique-character languages

Barcode

2D codes

Speed

Another important factor to consider is the speed of coding. CIJ coders have a faster printing speed compared to UV laser coders. This makes them ideal for high-volume production lines where fast coding is essential. However, with advancements in technology, UV lasers are becoming more efficient and can now compete with some CIJ coders in terms of speed.

Versatility

CIJs can create a permanent mark on almost any substrate regardless of color, texture or shape, making them a popular choice for industries that need to mark on a wide variety of materials. However, the versatility of CIJ also extends to the types of inks that can be used. Different inks serve a unique purpose, and each industry has its own requirements for marking and coding.

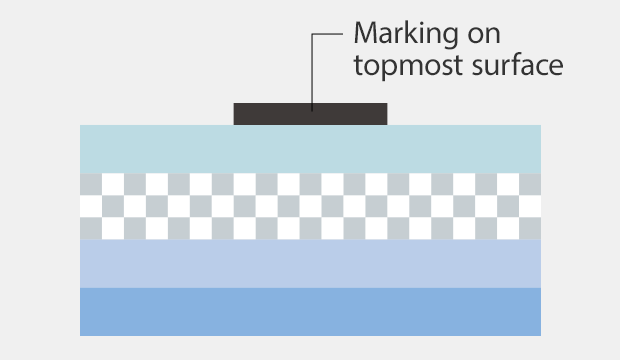

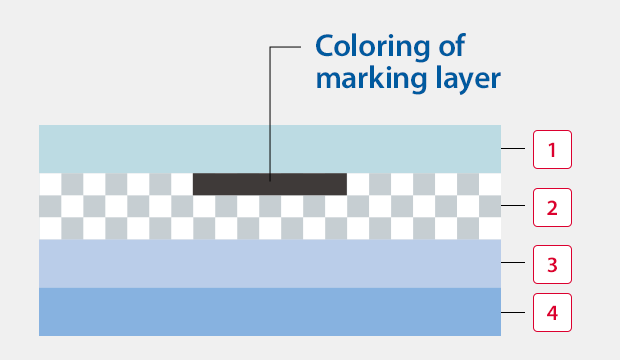

UV laser coders can also mark on most materials, but the contrast of the date or lot code may vary depending on the surface. On clear materials, in particular, the marking may not be as visible as it would be with traditional black ink. However, it is important to note that while adhesion is good with CIJ printing, it will never be as permanent as a laser mark.

Conventional ink-based systems

UV laser coder

-

1Laminated surface (transparent)

-

2Marking layer

-

3Other film layers

-

4Sealant layer

Curious about our pricing?

Click here to find out more.

Continuous Inkjet Printer for Packaging: Efficiency and Versatility

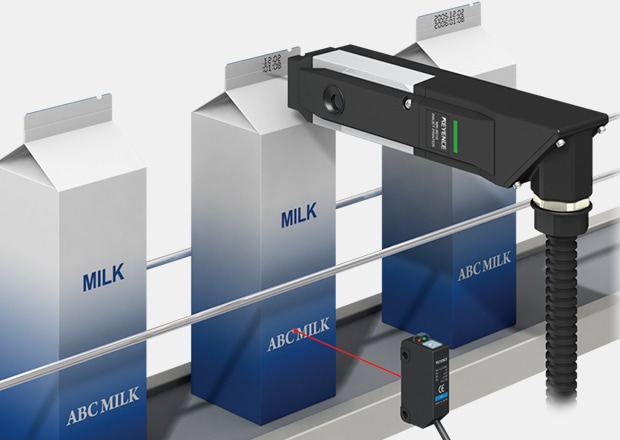

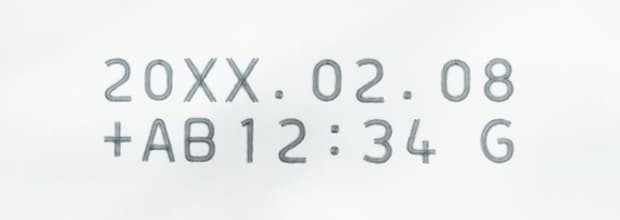

The KEYENCE MK-G Series continuous inkjet printer (CIJ) is a popular choice in the packaging industry due to its high-speed, adaptable, non-contact printing from any direction. It also easily integrates into existing machinery like filling or labeling systems, ensuring quick and hassle-free installation.

With a compact printer head, the MK-G Series offers versatility, easily fitting into tight production spaces and optimizing factory floor usage and packaging line layouts.

The MK-G Series prints on a wide range of surfaces, accommodating different-shaped containers, including curved surfaces like flexible packaging or bottles and cans crafted from materials such as plastic/PET, glass, metal, and paper — making it an ideal solution for diverse packing needs.

Cartons

Plastic/PET bottles

Discover more about this product.

Click here to book your demo.

UV Laser Coding on Packaging: Clarity and Durability

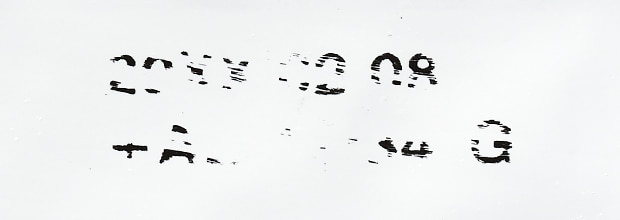

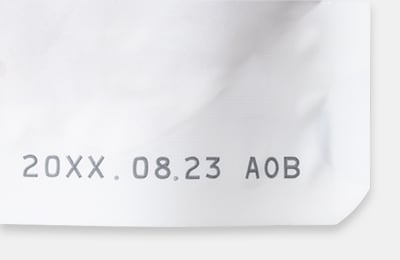

KEYENCE FP-1000 Series UV Laser Coder offers precise, permanent coding on various packaging materials. UV laser coders provide unmatched clarity, ensuring readable codes. Unlike traditional ink-based systems, it eliminates the risks of incomplete or faded markings.

The FP-1000 Series contrast marks the film itself instead of using external ink, making it resistant to oil, powder, water, and contaminants, resulting in damage-free codes that don’t fade over time.

Another key advantage of UV laser coding is its durability. Unlike conventional infrared lasers that can damage packaging due to high heat, UV lasers emit shorter wavelengths, reducing heat generation and preventing harm to delicate materials like plastic films and pouches.

UV laser coding is also an environmentally friendly solution. As it does not use external ink or consumables, it eliminates the need for regular maintenance and reduces waste production. This ultimately leads to cost savings and a more sustainable production process.

UV Lasers Are Not Affected by Traditional Causes of Marking that Fades Away

Oil

Powder

Alcohol

Heat sterilization

Conventional thermal printer

UV laser coder

* Results comparison after rubbing on the marked area of film exposed to powder before marking

-

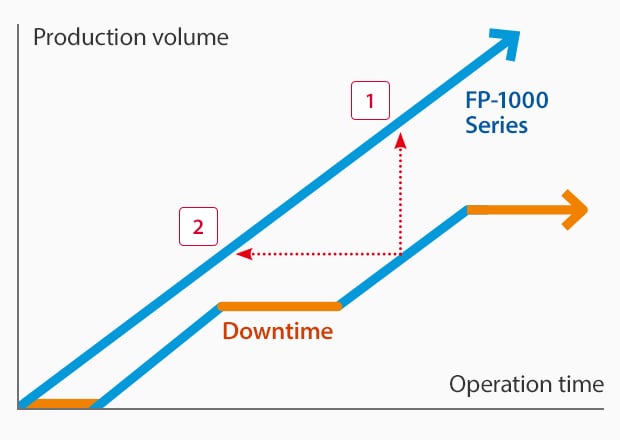

1More production in the same amount of operation time

-

2Less operation time for the same production volume

Get detailed information on our products by downloading our catalog.

View Catalog

Choosing the Right Flexible Packaging Coding and Marking Solution

At KEYENCE, we offer a wide range of high-quality and reliable flexible packaging coding and marking solutions that cater to various industries and applications. Our team of experts can help you assess your requirements and recommend the most suitable technology for your business.

Don't compromise on the quality or efficiency of your coding process. Contact us now to find out how we can provide you with the perfect solution for all your flexible packaging coding needs!

Clear Ink-Based Marking for a Wide Range of Objects

Continuous Inkjet Printer MK-G Series

Cartons

Tramsparent films

UV Laser Marking on Various Types of Packing Film

UV Laser Coder FP-1000 Series

Soft packaging materials

Pouches

We’re here to provide you with more details.

Reach out today!

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper

![Packaging Technology Introduction [Packaging Machine Edition]](/img/asset/AS_82098_L.jpg)