Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Simplify Any Case Coding Setup with CC‑1000 Series, the World’s First Smart Multi-Sensing Unit

Case coding automation is only as effective as the conditions surrounding it, and on high-speed lines, these conditions often fluctuate. Yet fluctuating line speeds, box vibration, and mechanical collisions often disrupt even well-calibrated systems.

The KEYENCE CC‑1000 Series’ SMART Multi-Sensing Unit (MSU) overcomes these challenges. This integrated system actively adapts to production line conditions, correcting errors before they happen. From line setup to high-speed runtime, the MSU brings intelligent control to every phase of the print process.

Why the SMART MSU Matters for Print Quality

Print quality issues often arise from more than just the printhead. Slight variations in conveyor motion, target distance, or substrate stability can result in misaligned barcodes, stretched data matrix codes, or dropped characters. Traditional systems rely on rigid parameters and manual calibration, leaving room for inconsistency.

Blurred codes

Wavy codes

The CC‑1000 Series SMART MSU solves this by monitoring and adjusting to real-time conditions. With sensors that monitor vertical distance, line vibration, and product movement, the system maintains clean print geometry even when the line isn’t perfect. High-density 360 DPI printing provides sharp barcodes and logos, and the built-in camera confirms output integrity without operator intervention. By continuously adapting to variable conditions, the MSU supports consistent quality from box to box.

We’re here to provide you with more details.

Reach out today!

Why the MSU Is Essential for Efficient and Reliable Printing

Line stability affects more than print appearance; it directly impacts productivity and maintenance. In conventional setups, print variation often goes unnoticed until products are rejected downstream, or reach customers with unreadable codes.

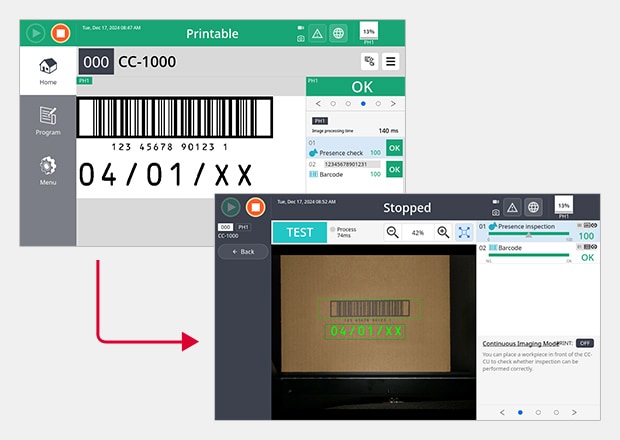

Zero print distortion

The SMART MSU addresses these issues with real-time adjustments and automatic alerts. It tracks print triggers, monitors movement, and compensates for dynamic changes like vibration or speed spikes. As part of a fully integrated system, these sensing functions enable case coder automation without the complexity of third-party equipment or manual calibration.

Automatic synchronization of print and inspection settings

Because the sensors are fully integrated with the print logic, there’s no need for additional setup, alignment, or software. Print and inspection parameters synchronize automatically, and built-in maintenance tools, such as one-touch head core replacement and nozzle self-cleaning, minimize downtime. Compared to modular third-party inspection systems, the CC‑1000 Series provides a compact, intelligent solution with significantly lower operational overhead.

CC‑1000 Series’ 4 Sensor Capabilities

The SMART Multi-Sensing Unit combines four sensing functions into a single device:

- Print Trigger Detection: Confirms when a box is present and ready for print, even if its position fluctuates.

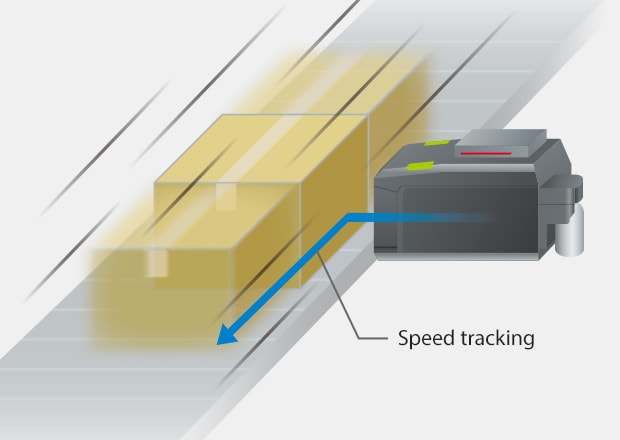

- Speed Change Tracking: Compensates for fluctuations in conveyor speed to maintain accurate print timing and prevent barcode stretching.

- Distance and Vibration Detection: Measures vertical displacement and vibration to maintain stable character alignment.

- Head Collision Detection: Identifies unexpected box contact and prevents damage by pausing the operation to avoid potential harm.

Each sensor works in concert with the CC‑1000 Series’ high-resolution print engine and inspection camera. The system doesn’t just react to issues; it prevents them by proactively adjusting output with every unit.

Curious about our pricing?

Click here to find out more.

Print Trigger Detection

Accurate triggering is essential for alignment. If printing starts too early or too late, even a high-resolution print file will miss its mark. The CC‑1000 Series uses precise laser-based print trigger detection to identify the target position with sub-millimeter accuracy.

Unlike mechanical or light gate systems, this sensor accommodates product variations without requiring adjustments. The result is consistent placement, reduced waste, and better print quality monitoring at high speeds. This level of responsiveness is especially important when handling varied carton sizes or staggered box spacing, where standard trigger setups often fail. By automating this process, the system enables true case coder automation without added hardware or configuration steps.

Speed Change Tracking

Conveyor speed doesn’t stay constant; variations from product spacing, accumulation, or operator intervention can alter timing within seconds. Even minor fluctuations can distort printed barcodes, stretch characters, or cause misreads in downstream scans.

The MSU compensates automatically. A four-point red LED sensor monitors real-time velocity, adjusting the printhead’s timing with each pass. This keeps horizontal print dimensions consistent, so barcode ratios remain within readable tolerances even when the line speed drops mid-cycle.

By synchronizing print pulses with conveyor motion, the CC‑1000 Series avoids the resolution loss common in systems that operate with static or encoder-only triggers.

Discover more about this product.

Click here to book your demo.

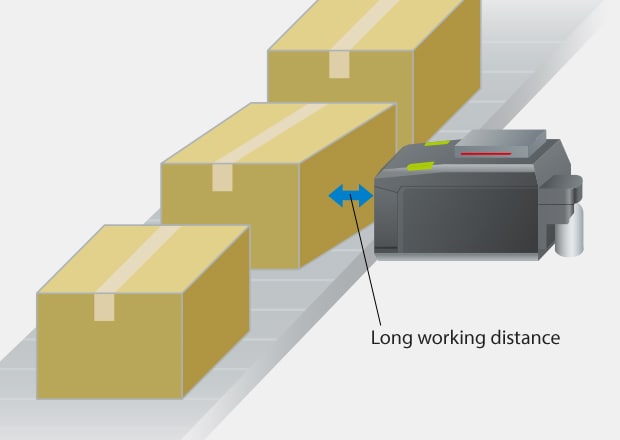

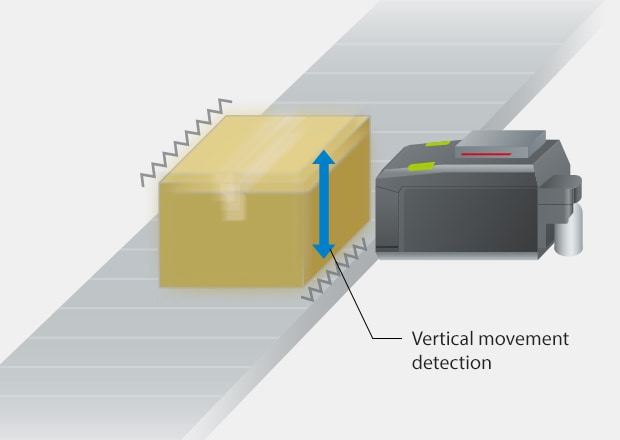

Distance & Vibration Detection

Rigid printhead mounting only goes so far. On roller conveyors or automated lines, product bounce and lateral motion introduce subtle but significant shifts in vertical distance. When left uncorrected, these shifts can cause ink misting, blurred codes, or nozzle impact.

The MSU’s dual-laser system tracks vertical offset and vibration in real time. It flags when box position deviates beyond tolerance, and its long-throw printhead design (up to 15 mm 0.6″) makes sure the head remains clear of collisions even when box alignment is imperfect.

This is particularly important for mixed SKUs or unsealed cartons where surface height varies. With built-in vibration and distance detection, the CC‑1000 Series maintains legibility and prevents wavy codes caused by vibration and box weight variation, all without sacrificing speed.

Head Collision Detection

Unplanned box contact can damage nozzles, causing production to come to a halt. Where older systems rely on crash sensors or stop switches, the SMART MSU detects head collision risks early and reacts instantly.

By analyzing data from onboard sensors, the MSU detects when a box is misaligned or about to collide with the printhead. It can pause printing the moment excess vibration or collision occurs, notify the operator, and resume once alignment is restored.

This feature also helps identify misfeeds or irregular packaging shapes that can cause cumulative alignment issues. Preventing contact protects both print quality and the lifespan of the hardware.

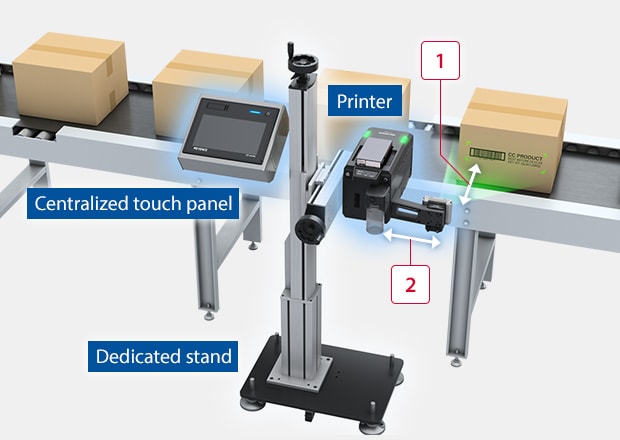

Simplify Your Printing Setup with the CC‑1000 Series’ SMART MSU

Installing a new coder typically requires encoder configuration, separate inspection equipment, and manual fine-tuning across several SKUs. The CC‑1000 Series changes that. With a single, unified system that handles sensing, printing, and inspection, setup becomes faster and far less prone to errors.

All print and inspection parameters are managed through one interface. There’s no need for external calibration, vision alignment, or camera scripting. Whether the line changes speed, the product changes size, or packaging conditions shift, the SMART MSU adapts automatically without requiring additional programming.

-

1Fixed distance for ideal lighting and field-of view

-

2Fixed distance for optimal print inspection

For operations that manage frequent changeovers or aim to reduce training time, the CC-1000 Series offers a future-ready solution designed for real-world flexibility.

Request a CC-1000 Series demo today and experience how integrated sensing and printing can eliminate complexity while protecting code quality. Contact a KEYENCE specialist to schedule your personalized demo.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can the MSU Auto-Adjust for Sudden Speed Spikes?

Yes. The speed tracking sensor continuously measures line velocity and adjusts the print timing frame by frame.

How Does Vibration Detection Safeguard Code Legibility?

The MSU detects vertical motion and compensates for it in the print logic, preventing wavy or blurred characters.

Is MSU Calibration Required After Installation?

No. The sensors are pre-aligned and integrated directly with the printer logic, eliminating the need for separate calibration or teaching.

What Makes the CC-1000 Series’ SMART MSU Different from Traditional Coding Systems?

It replaces multiple hardware modules, trigger sensors, encoders, and inspection cameras with a single integrated device that adjusts in real time.

Can the MSU Handle High-Speed Production Lines?

Yes. The MSU supports up to 197 ft/min (60 m/min) with precise print control and inspection at full speed. The CC-1000 Series itself can handle speeds upwards of 328 ft/min (100m/min).

What Industries Benefit Most from the CC-1000 Series’ MSU?

Any operation that prints on cardboard cases, especially in the food, beverage, personal care, and logistics industries, will benefit from simplified setup and high-speed consistency.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper