Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

CIJ Coding for Packaged Foods | High-Quality Marking Solutions

Every packaged item that is shipped from a food production line must carry accurate data through batch numbers, expiration dates, and lot codes that connect products to their source. Reliable printed information protects consumers, supports compliance, and keeps production running. With advanced continuous inkjet (CIJ) printers for food packaging, manufacturers gain a dependable way to keep codes clear and legible across every material on the line.

Coding Solutions for the Packaged Foods Industry

Packaged food lines operate at high speed and under constant demand. From flow-wrapped snacks to frozen entrées, each product type introduces new variables such as curved surfaces, condensation, and tight label space. Meeting those challenges calls for packaged food coding solutions designed for industrial food packaging.

KEYENCE CIJ systems deliver consistent print performance without slowing production. Non-contact printing adapts to film, plastic, cartons, and glass with precision. Automatic ink conditioning and stable droplet control keep codes sharp through long shifts. The result is a readable mark that withstands handling, transport, and temperature changes common in packaged foods.

We’re here to provide you with more details.

Reach out today!

The Importance of Accurate Food Packaging Codes

Accurate coding is part of food safety and consumer confidence. Every printed lot code and expiration mark links production data to traceability records. Missing or unclear information can cause recalls, compliance issues, and wasted product. Reliable date coding for packaged foods helps identify when and where an item was made, supports inventory rotation, and protects brand reputation.

Regulatory expectations across the food industry continue to grow. Clear, durable print supports packaging compliance coding for distributors, retailers, and auditors. High-quality marking also communicates transparency to customers. A crisp, easy-to-read code signals accountability and professionalism in every package.

Applications for Date Coding in Packaged Foods

Food packaging comes in nearly every shape and material. Pouches, trays, sleeves, and coated cartons each present a different surface and workflow condition. CIJ technology handles these variations with steady output at production speed. Printing lot codes on food packaging often means dealing with moisture, curved surfaces, and limited clearance. The fine droplet stream of a CIJ printer can mark those surfaces without contact, avoiding smears or transfer.

In industrial food packaging, flexibility is key. CIJ systems maintain adhesion on both porous and non-porous materials while using fast-dry inks that stay readable in cold or humid environments. Each mark carries production data such as best-before dates, batch numbers, or serialized lot codes tied directly to traceability systems. Consistent coding across packaging types keeps visibility strong from processing to shipment.

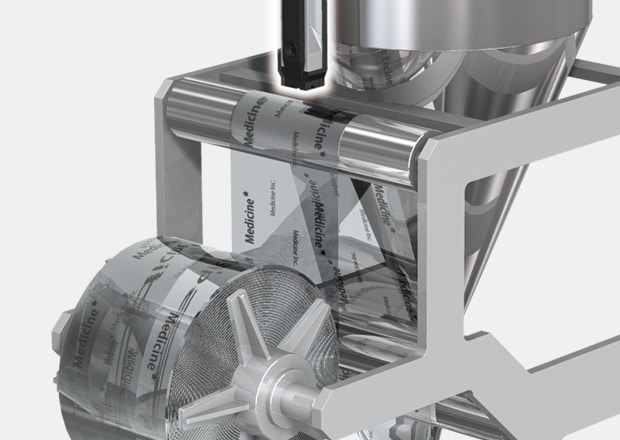

Films

Packaged foods date coding mistakes can cause spoilage and customer dissatisfaction. KEYENCE CIJs ensure compliance with strict date coding regulations, providing reliable, high-quality, and accurate date and lot codes on packaged foods.

Printing example

Installation example

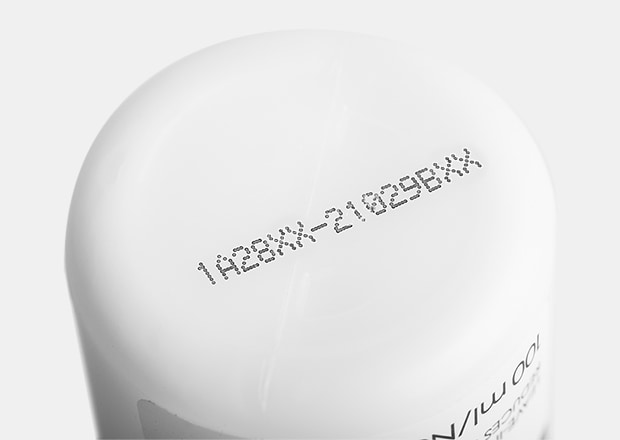

Containers and Caps

In coding on packaged foods, container shapes can challenge manufacturers. KEYENCE industrial inkjet printers solve this with non-contact printing, ensuring clear, legible product information on curved surfaces.

Printing example

Installation example

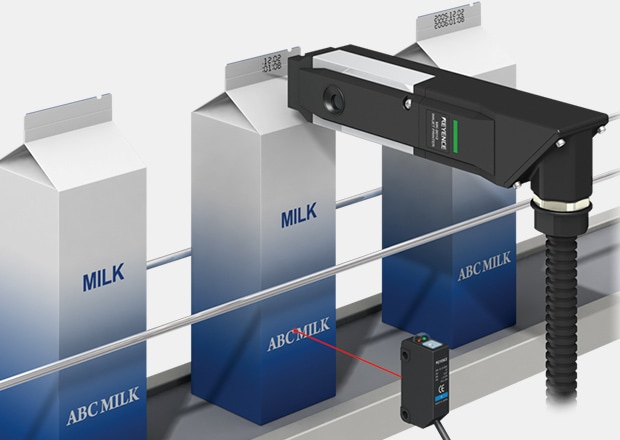

Cartons

Incorrect or missing date codes can spoil carton-packaged foods. KEYENCE CIJs ensure accurate, visible date codes on various surfaces with non-contact printing technology.

Printing example

Installation example

Hard Plastic Containers

Hard plastic containers need durable date codes for traceability. KEYENCE CIJs mark PP and PET containers with high throughput/marking speed, ensuring quality in high production volumes.

Printing example

Installation example

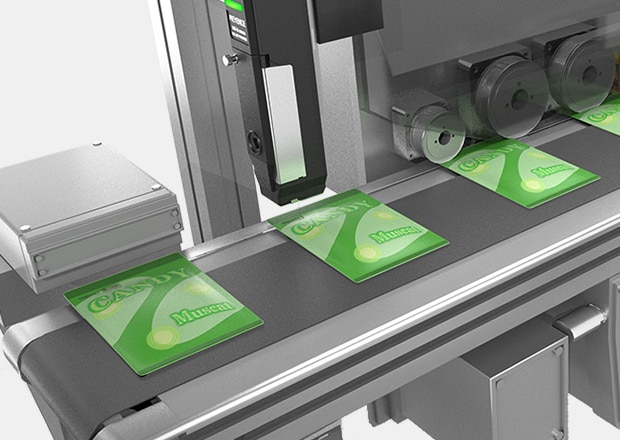

Flexible Plastics

Stamps or labels are hard to use on flexible plastic packaging due to the uneven surface. KEYENCE CIJs offer automatic maintenance, troubleshooting, and easy nozzle replacement, reducing downtime and increasing productivity.

Printing example

Installation example

Pouches

Traditional methods are often expensive, time-consuming, and ineffective. Stamps/labels may not adhere well to flexible pouches. KEYENCE CIJs print on various packaging materials, including PET, PP, PE, and more.

Printing example

Installation example

Curious about our pricing?

Click here to find out more.

Challenges in Coding and Marking for Packaged Food Industry

- Packaging Material Limitations

Each material's unique properties demand different printing approaches. KEYENCE CIJs deliver high-quality, smudge-resistant coding on packaged foods and can print on curved, irregular, and textured surfaces. - Regulatory Requirements

Non-compliance with regulations leads to fines, recalls, lost contracts, and reputation damage. KEYENCE CIJs can work in tandem with vision systems to easily print and verify batch numbers and expiry dates, ensure traceability, and identify defective products. - Maintaining Coding Consistency Across Different Production Lines

A major challenge in coding on packaged foods is ensuring consistency across different production lines. KEYENCE CIJs eliminate rework and scrap by integrating across varying lines. They mark multiple materials with dates, lot numbers, and safety codes.

CIJ for Packaged Food

KEYENCE CIJs stand out for their fast and accurate coding capabilities. They enable manufacturers to identify and trace defective or substandard products. This feature is crucial in the packaged food industry as it ensures that only high-quality products reach consumers.

CIJ technology minimizes the chances of human error in packaged food coding and marking processes. This leads to more reliable and efficient coding, ensuring that all packaged food products are accurately labeled with the correct information.

Why Choose KEYENCE CIJ Printers for Packaged Food Date Coding

KEYENCE developed its MK-G Series CIJ printer for food packaging to meet the demands of high-volume production, featuring automatic cleaning, smart startup and shutdown routines, and a stainless-steel housing rated IP55 for damp or washdown environments. These systems reduce maintenance and downtime, letting operators focus on production.

Stable ink circulation and precise viscosity control support long runs while maintaining drop accuracy, while fast-dry and MEK-free inks provide strong contrast on flexible film, PET, and coated cartons. A compact printhead simplifies integration beside conveyors or fillers, while internal diagnostics and event recording help supervisors track line performance.

Benefits of CIJ Technology for Packaged Foods

Continuous inkjet printers feature non-contact operation, which prevents damage to packaging while supporting high throughput. Automated ink management minimizes waste, and durable components limit downtime between runs. Operators gain simple control through an intuitive interface that shortens setup time during product changeovers.

In packaged food coding solutions, this reliability supports consistent coding, dependable compliance, and long-term cost control. CIJ technology adapts as packaging designs change, giving producers confidence that each printed code will remain traceable and legible when products reach store shelves.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Date Coding in the Packaged Food Industry

What Are the Date Coding and Lot Coding Requirements in the Food Packaging Industry?

Packaged foods date coding indicates shelf life, expiration date, and production batch. Packaged food coding and marking are essential for tracking, traceability, and ensuring food safety and quality.

Can KEYENCE's MK-G Series CIJ Coder Accommodate the Diverse Packaging Materials Used in the Pre-packaged Food Industry?

Yes, the KEYENCE MK-G Series CIJ coder is designed to accurately print on a wide range of packaging materials including paper, cardboard, plastic, metal and even glass surfaces.

What Specific Industry-First Features Does KEYENCE's CIJ Introduce to Enhance Production Efficiency and Reliability in the Packaged Food Manufacturing Industry?

KEYENCE CIJs have introduced; MIL standard-compliant impact-resistant print head structure, a self-diagnosing and troubleshooting smart dock, a backup power module, and an event recording function.

What Are the Benefits of Using CIJ Solutions for Quality Control and Product Identification in Date Coding in the Packaged Food Sectors?

There are several benefits: easy integration with vision systems/inspection equipment to verify presence of printed content and enhance compliance with regulations, no compromise on accuracy for speed, traceability and product safety, and minimal down time for cleaning and maintenance.

How Does KEYENCE's MK-G Series Technology Contribute to Reducing Downtime and Increasing Productivity in Packaged Food Date Coding?

KEYENCE's MK-G Series technology minimizes downtime in packaged foods date coding with self-diagnosing capabilities and step-by-step instructions and videos, enabling easy troubleshooting, free printer monitoring network connectivity, rapid nozzle clog recovery with a patented one-touch nozzle replacement, and email alerts for unmatched production visibility.

What Is a CIJ Printer, and How Does It Work for Packaged Foods?

A CIJ printer projects tiny ink droplets onto moving products without contact, marking curved or uneven surfaces at line speed with sharp, durable print.

Why Is Coding Important in Packaged Food Production?

Printing lot codes on food links each product to its production data, supporting traceability, freshness checks, and regulatory compliance.

How Does CIJ Printing Improve Packaging Compliance?

CIJ systems produce consistent, legible codes for audits and recalls, while automated cleaning and ink control keep data accurate.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)