Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Benefits of Automatic Print Inspection in Case Coding

Ensure flawless case coding with real-time automatic print inspection—eliminate misprints, reduce costly errors, and maintain packaging integrity across high-speed production lines.

Understanding Automatic Print Inspection

The fastest lines in manufacturing can churn out thousands of boxes per hour. In such an environment, even a single misprinted code isn’t just a blemish; it’s a potential bottleneck, a costly recall, or a missed delivery window. For manufacturers who rely on printed codes for packaging traceability, product integrity, and line efficiency, manual spot checks are no longer sufficient.

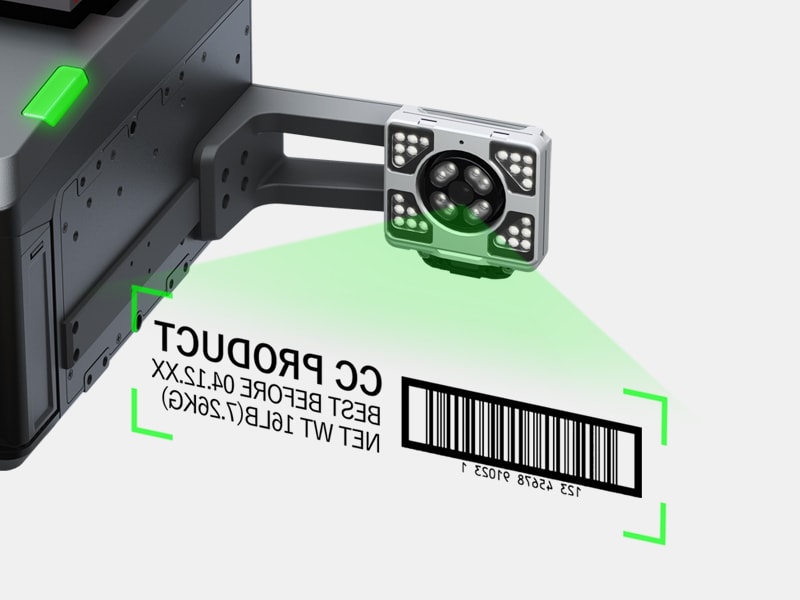

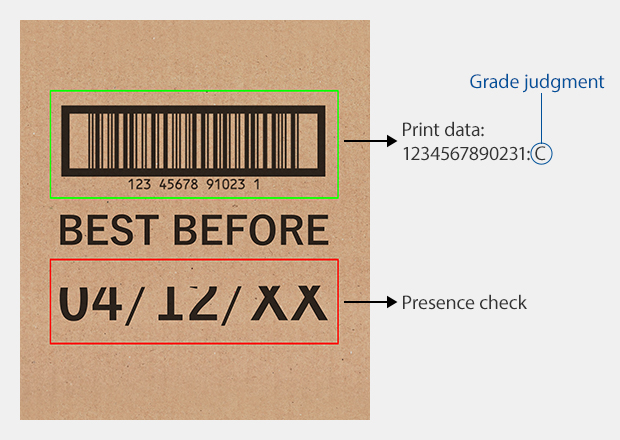

Automatic print inspection solves this by checking every printed code the moment it comes into contact with the surface. These systems scan every code in real time, detecting print fading, smudges, skewed characters, and barcode readability issues as they occur. They’re built to verify presence, legibility, and accuracy without slowing production, offering a level of case coding accuracy that’s impossible with traditional methods.

Print inspection isn’t limited to OCR or barcode reads anymore. When connected directly to case coders, the inline print verification logic mirrors what’s actually printed, eliminating mismatches between expected and actual output. This means that every code is verified not only for its format but also for its print quality on the packaging, ensuring it meets the required standards.

We’re here to provide you with more details.

Reach out today!

How Automatic Print Inspection Transforms Case Coding

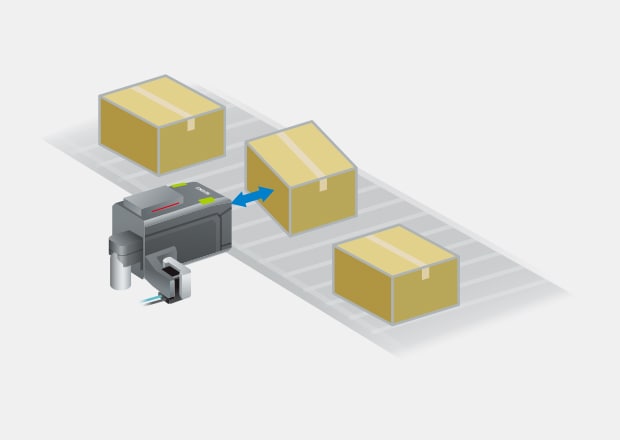

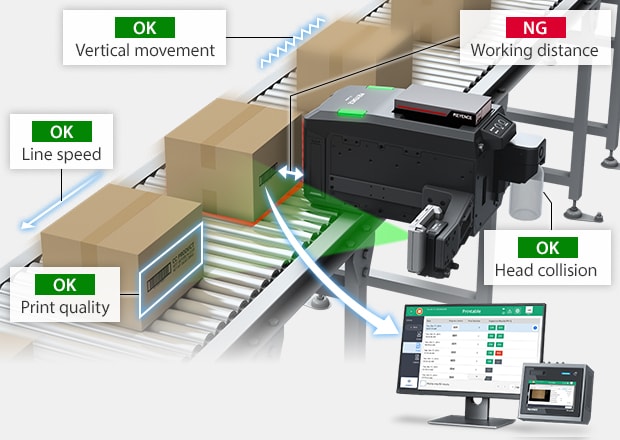

Most coding issues don’t stem from faulty equipment, but from factors that occur between scheduled checks, such as printhead misalignments, material variations, worn nozzles, speed changes, or ambient vibration.

Product shifting out of print range

Vibration detection

Automatic synchronization of print and inspection settings

Print inspection for packaging tracks codes from the moment they’re applied, comparing them to expected parameters and triggering rejections or alerts the instant something goes wrong. This prevents faulty codes from reaching the next station. When linked directly to the case coder, inspection settings adjust automatically based on the selected print program, eliminating the risks of manual synchronization errors.

Reducing Errors and Enhancing Quality in Case Coding

No production team wants to deal with re-labeling, rework, or worse, a recall over a smudged expiration date. Yet, those problems persist on lines where inspection still relies on manual checks or periodic audits. It’s not just the mistakes that cost money; it’s the time lost discovering them.

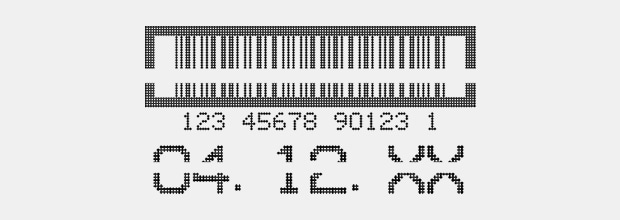

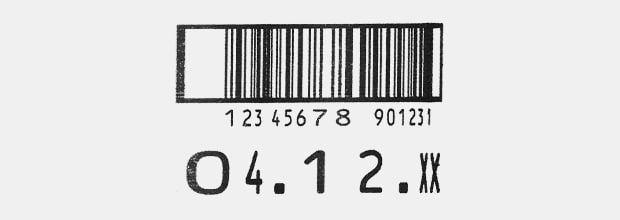

Missing lines

Stretched or compressed codes

Automatic print inspection helps maintain consistency on packaging lines that deal with constantly changing box sizes, substrates, or print conditions. Vision systems detect common defects like missing characters, streaking, distorted barcodes, or faded ink. They flag bad prints automatically, isolate the issue, and give operators the chance to address it without halting the entire line.

Instead of depending on human eyes to catch fast-moving codes, systems designed for industrial print quality control verify every mark as it's made. That consistency doesn’t just reduce mistakes; it reinforces case coding accuracy.

Curious about our pricing?

Click here to find out more.

Detecting Print Quality Degradation Early for Proactive Maintenance

Over time, even a well-calibrated printhead will lose fidelity. Nozzle clogs, vibration, and ink flow inconsistency all lead to blurry or broken characters that don’t scan.

The key difference with inline print verification is timing. It detects issues before they escalate. With integrated vision hardware, these systems flag quality drops as they emerge, giving operators the data they need to take immediate action, whether it’s a quick clean, a swap, or a simple adjustment to keep the line running.

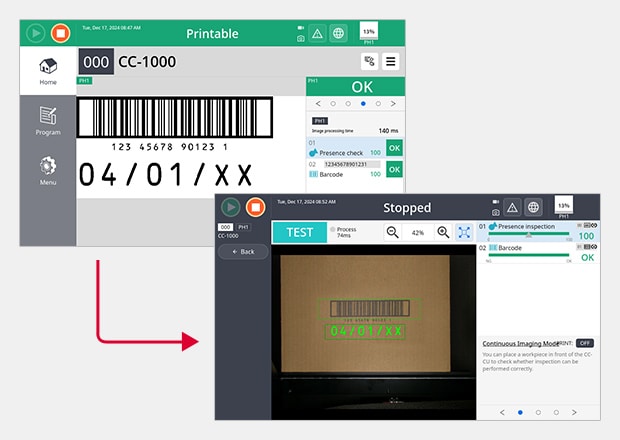

In KEYENCE integrated setups, print and inspection settings are linked, and the system automatically adjusts inspection thresholds when switching print jobs. This eliminates the need for separate calibration, and more importantly, removes room for error when jobs change mid-shift.

Simplified Setup and Operation with Integrated Inspection Systems

One of the common hurdles in industrial print quality control has always been complexity. Multiple devices mean multiple settings, and the more manual adjustments needed, the more likely something gets missed.

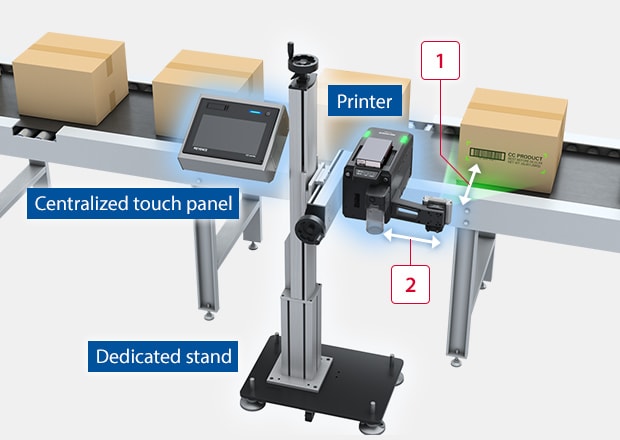

Modern inspection setups remove that friction. Integrated systems configured through a unified interface reduce setup time and training overhead. When inspection cameras are integrated into the printer's control panel, users only need to configure the job once.

-

1Fixed distance for ideal lighting and field-of view

-

2Fixed distance for optimal print inspection

On systems like the KEYENCE CC-1000 Series, the integrated vision camera connects directly to the controller and synchronizes automatically with the selected print settings. Inspection parameters are updated whenever the print job changes, keeping the inspection target aligned with what is actually being printed.

This camera is also specifically engineered for reliable inspection on cardboard surfaces. It not only verifies the presence or absence of printed codes but also reads barcodes and 2D codes with precision, ensuring they are present, legible, and scannable. Its tailored design guarantees consistent performance on the unique texture and color variations of cardboard packaging.

Discover more about this product.

Click here to book your demo.

Future Trends in Print Inspection Technology

Case coding is a part of a larger chain that includes data capture, production monitoring, and packaging traceability. As supply chain expectations continue to rise, so does the need for inspection systems that provide full visibility without slowing throughput.

Operation status visualization

* Example using multi-sensor unit

The push toward smarter inspection has already begun. Systems are trending toward more real-time defect logging and intelligent alarms that distinguish between critical faults and minor fluctuations. Print inspection for packaging isn’t just about quality anymore; it’s about data. Inspection images and metadata can be stored and accessed for audits, root cause analysis, and long-term optimization.

The latest KEYENCE systems store inspection images alongside pass/fail data, allowing teams to investigate print quality shifts after the fact. This kind of traceability turns inspection from a reactive safety net into a forward-looking analytics tool.

Upgrade to real-time print inspection with KEYENCE. Contact us today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Is Barcode Readability Verified on Cardboard?

Vision systems grade barcode quality according to ISO standards and are specifically calibrated to handle textured substrates, such as corrugated cardboard.

What Industries Benefit Most from Case Coding Inspection?

Industries with traceability requirements, such as food, beverage, pharma, and consumer goods, see the greatest gains from automatic print inspection.

How Does Automatic Print Inspection Differ from Manual Inspection?

Manual checks sample a fraction of prints and rely on human consistency. Automatic systems perform inline print verification in real time with objective criteria.

How Does Automatic Print Inspection Reduce Overall Costs?

It prevents bad products from advancing, eliminates rework, reduces labor strain, and minimizes the chance of costly recalls or missed compliance targets.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper